Preparation method of photo-Fenton ceramic membrane for water treatment, device and use method

A ceramic membrane and water treatment technology, applied in the field of water treatment, can solve problems such as cost reduction, inability to utilize sunlight, coating peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

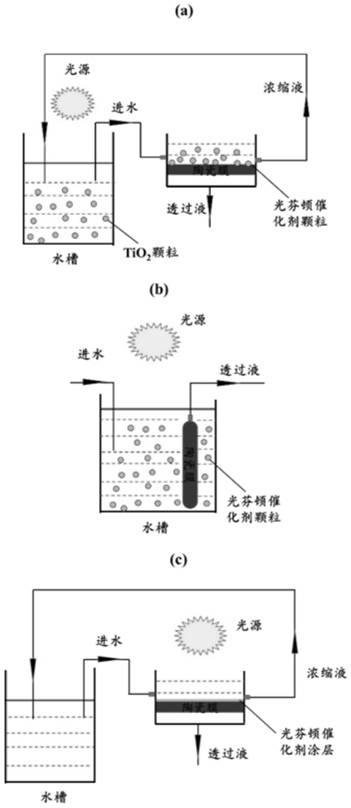

[0069] Embodiment 1 Assembly of the device of the present invention

[0070] Such as Figure 4 As shown, the device of the present invention is assembled: the device for water treatment by the optical Fenton ceramic membrane is composed of at least one treatment unit, each treatment unit includes a waste water tank 1, a ceramic membrane reactor 2, and a permeated liquid that are connected in sequence. Groove 3; A gas-liquid mixing pump 4 is arranged between the waste water tank and the ceramic membrane reactor, which is used to mix air and waste water and then pump it into the ceramic membrane reactor; 2 o 2 Liquid tank 8, used for H in the process of mixing air and waste water 2 o 2 The flow is mixed together by a gas-liquid mixing pump; a photo-Fenton ceramic membrane module 5 is arranged in the waste water tank; the photo-Fenton ceramic membrane module includes at least one piece of photo-Fenton ceramic membrane 6. Further, the H 2 o 2 The circulating liquid pump 7 co...

Embodiment 2

[0071] Example 2 Light Fenton Ceramic Membrane Laboratory Small-scale Treatment of Antibiotic Wastewater

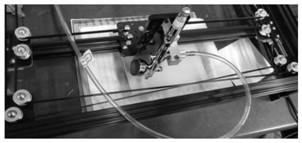

[0072] The main component of the flat ceramic membrane used (Shenzhen Huahuai New Material Co., Ltd.) is α-Al 2 o 3 , 43 channels, pore diameter 0.1μm, external dimensions 150mm×510mm×4mm, effective membrane area 0.15m 2 , pure water flux is 100m 3 / (m 2 h), the maximum operating pressure is -0.1~0.3MPa. During the experiment, the ceramic film was cut into 150mm×90mm×4mm by a water tank cutting machine for use. The cut ceramic film was ultrasonically washed with a mixed solution of distilled water: absolute ethanol: acetone (1:1:1) for 2 hours, then washed with distilled water and dried in an oven at 80°C. Store in a desiccator. Take 0.01g of solvothermal preparation [40] α-Fe 2 o 3 Nanosheet (particle size 20-50nm, specific surface area 6-10nm) photo-Fenton catalyst powder, then add 10mL of absolute ethanol solvent, 500W ultrasonic dispersion for 60min, use smal...

Embodiment 3

[0077] Example 3 Solar Fenton Ceramic Membrane Pilot Scale Treatment of Dye Wastewater

[0078] The main component of the flat ceramic membrane used in this case is α-Al 2 o 3 , 43 channels, pore diameter 0.1μm, external dimensions 150mm×510mm×4mm, effective membrane area 0.15m 2 , pure water flux is 100m 3 / (m 2 h), the maximum operating pressure is -0.1~0.3MPa. During the experiment, the ceramic film was cut into 150mm×200mm×4mm by a water tank cutting machine for use. The cut ceramic membrane is ultrasonically washed with a mixed solution of distilled water: absolute ethanol: acetone (1:1:1) for 2 hours, then washed with distilled water and placed at 90°C (or any temperature between 80°C and 100°C). temperature) in an oven, take it out and cool it, and place it in a desiccator for later use. α-Fe made by solvothermal method 2 o 3 Nanosheet (particle size 20-50nm, specific surface area 6-10nm) photo-Fenton catalyst powder, hydrogenation treatment with hydrogen (speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com