Rotary hearth furnace and electric furnace reduction treatment process for stainless steel dedusting ash

A treatment process and rotary hearth furnace technology, which is applied in the direction of rotary drum furnace, process efficiency improvement, furnace, etc., can solve the problems of thin material layer in the furnace, retention, kiln body is easy to form rings, etc., to improve the heat transfer temperature difference , Improve efficiency, increase production capacity and restore quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

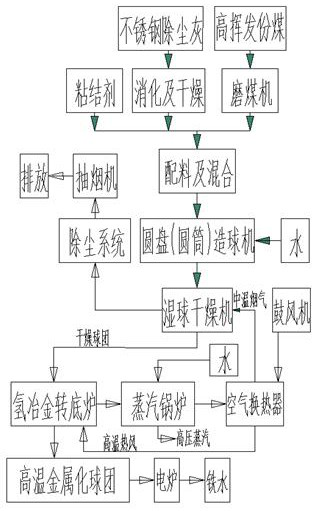

Method used

Image

Examples

Embodiment 1

[0048] A stainless steel dedusting ash rotary hearth furnace-electric furnace reduction treatment process, comprising the following steps:

[0049] S1 raw material treatment: stack the stainless steel dedusting ash with a moisture content above 6% in the site for conversion, so that the CaO entrained in the dedusting ash absorbs the moisture in the air and converts it into Ca(OH) 2 , and then dried for later use; select high-volatile coal with fixed carbon content of 44-46%, ash content of 7-9%, volatile content of 47-49%, particle size less than 20mm, preferably lignite, and high-volatile coal Grind until the particle size is less than 200 mesh, accounting for more than 80% for later use;

[0050] S2 material preparation: according to parts by weight, select 100 parts of stainless steel dedusting ash, 25 parts of lignite, and 2 parts of adhesive, and then carry out batching and mixing;

[0051] S3 pellet preparation: preparing the material obtained in step S2 into wet pellet...

Embodiment 2

[0055] A stainless steel dedusting ash rotary hearth furnace-electric furnace reduction treatment process, comprising the following steps:

[0056] S1 raw material treatment: stack the stainless steel dedusting ash with a moisture content above 6% in the site for conversion, so that the CaO entrained in the dedusting ash absorbs the moisture in the air and converts it into Ca(OH) 2 , and then dried for later use; select high-volatile coal with fixed carbon content of 44-46%, ash content of 7-9%, volatile content of 47-49%, particle size less than 20mm, preferably lignite, and high-volatile coal Grind until the particle size is less than 200 mesh, accounting for more than 80% for later use;

[0057] S2 material preparation: according to parts by weight, select 100 parts of stainless steel dedusting ash, 30 parts of lignite, and 2 parts of adhesive, and then carry out batching and mixing;

[0058] S3 pellet preparation: preparing the material obtained in step S2 into wet pellet...

Embodiment 3

[0062] A stainless steel dedusting ash rotary hearth furnace-electric furnace reduction treatment process, comprising the following steps:

[0063] S1 raw material treatment: stack the stainless steel dedusting ash with a moisture content above 6% in the site for conversion, so that the CaO entrained in the dedusting ash absorbs the moisture in the air and converts it into Ca(OH) 2, and then dried for later use; select high-volatile coal with fixed carbon content of 44-46%, ash content of 7-9%, volatile content of 47-49%, particle size less than 20mm, preferably lignite, and high-volatile coal Grind until the particle size is less than 200 mesh, accounting for more than 80% for later use;

[0064] S2 material preparation: according to parts by weight, select 100 parts of stainless steel dedusting dust, 35 parts of high volatile coal, and 3 parts of adhesive, and carry out batching and mixing;

[0065] S3 pellet preparation: preparing the material obtained in step S2 into wet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com