Phosphorus-nitrogen-containing liquid acrylate monomer and flame-retardant vinyl ester resin and preparation method thereof

A technology of vinyl ester resin and acrylate, which is applied in the field of preparation of liquid acrylate monomer and its flame-retardant vinyl ester resin, to achieve controllable process conditions, improve flame-retardant efficiency and smoke suppression performance, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

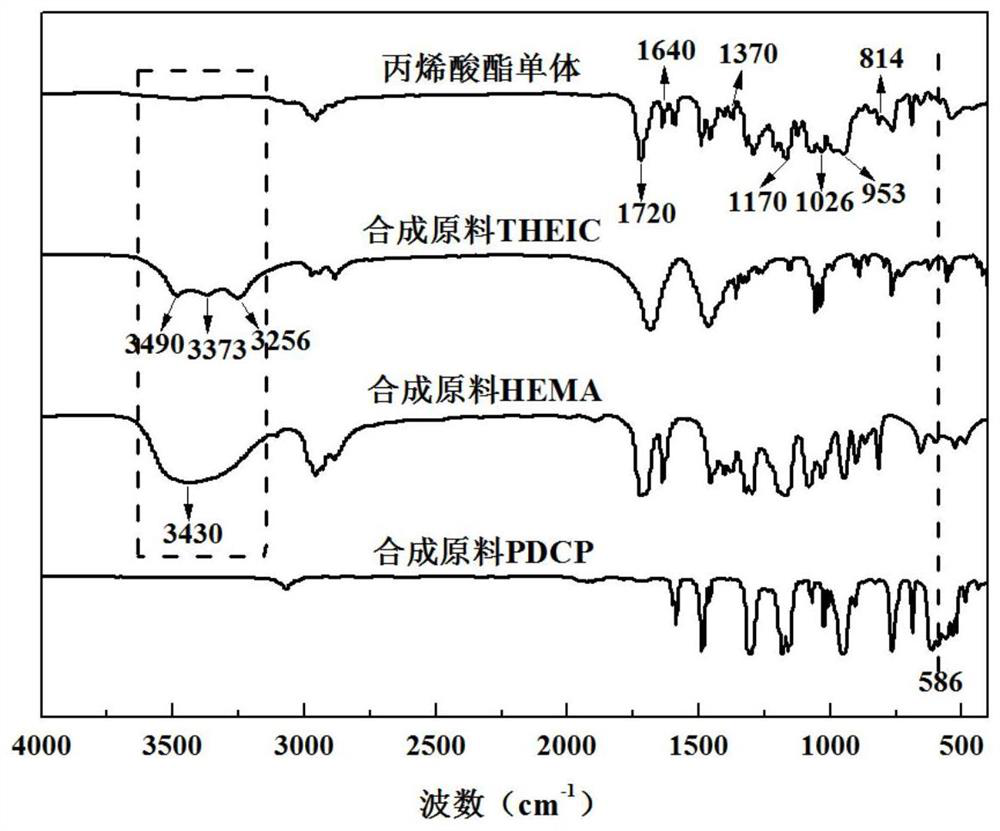

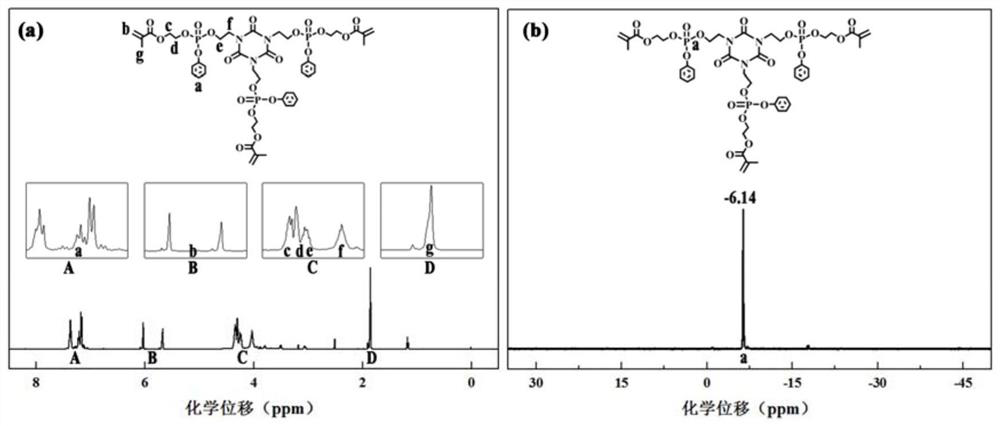

[0041] (1) Synthesis of liquid acrylate monomers containing phosphorus and nitrogen elements.

[0042] Add PDCP (22.79g, 0.108mol) and acetonitrile (350ml) in a 500ml four-neck flask equipped with a stirrer, dropping funnel, condenser and nitrogen inlet, then HEMA (14.04g, 0.108mol) , a mixed solution of triethylamine (21.86g, 0.216mol) and acetonitrile (30ml) was slowly added dropwise into a four-necked flask within 2h, and the stirring reaction was continued at this temperature for 4h. Then, catalysts 4-dimethylaminopyridine (0.63g, 2mol%) and THEIC (9.44g, 0.036mol) were added into the four-necked flask, and after stirring for 2h under ice bath, the temperature was raised to 85°C and kept for 12h. After the above system is cooled to room temperature, remove the triethylamine salt by suction filtration, pour the filtrate into a large amount of deionized water, obtain the crude product by extraction, wash it several times with deionized water, and then dissolve it in dichloro...

Embodiment 2

[0049] (1) See Example 1 for the synthesis method of the liquid acrylate monomer containing phosphorus and nitrogen elements.

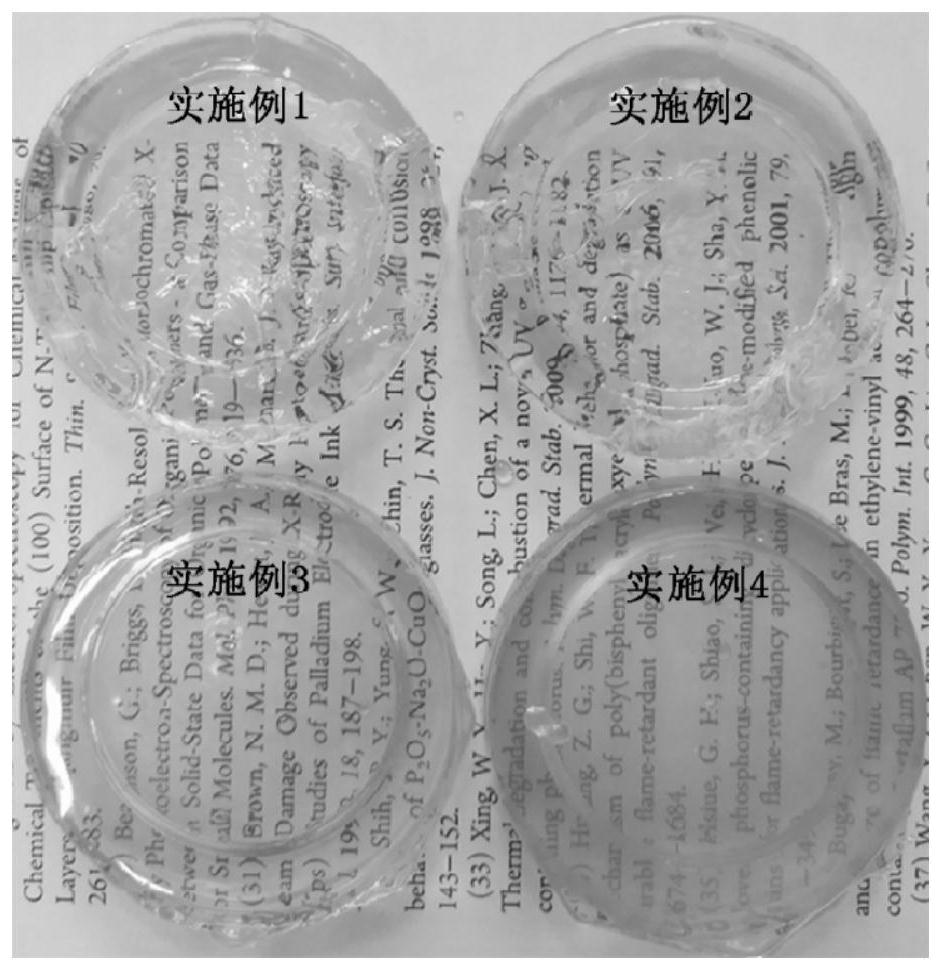

[0050] (2) Preparation of flame retardant vinyl ester resin cast body.

[0051] Add 90g of common vinyl ester resin (901-VER) and 10g of acrylate monomer flame retardant into a 100ml round bottom flask, stir vigorously at room temperature for 5min, then add 2g of benzoyl peroxide as an initiator in the flask, After stirring until the benzoyl peroxide is completely dissolved, take an appropriate amount of the mixture for process performance testing. Then degas the above mixture in a vacuum defoamer for 5 minutes, then pour it into a metal mold preheated in an oven at 80°C, and follow the curing system of 80°C / 2h+100°C / 2h+140°C / 2h The mixture is thermally cured. After the mold is naturally cooled to room temperature, it is demoulded, and an engraving machine is used to prepare the standard pattern required for the flame retardant performance test. The...

Embodiment 3

[0053] (1) See Example 1 for the synthesis method of the liquid acrylate monomer containing phosphorus and nitrogen elements.

[0054] (2) Preparation of flame retardant vinyl ester resin cast body.

[0055] Add 85g of common vinyl ester resin (901-VER) and 15g of acrylate monomer flame retardant into a 100ml round bottom flask, stir vigorously at room temperature for 5min, then add 2g of benzoyl peroxide as an initiator in the flask, After stirring until the benzoyl peroxide is completely dissolved, take an appropriate amount of the mixture for process performance testing. Then degas the above mixture in a vacuum defoamer for 5 minutes, then pour it into a metal mold preheated in an oven at 80°C, and follow the curing system of 80°C / 2h+100°C / 2h+140°C / 2h The mixture is thermally cured. After the mold is naturally cooled to room temperature, it is demoulded, and an engraving machine is used to prepare the standard pattern required for the flame retardant performance test. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com