High-viscosity anti-rut modified asphalt for ultrathin overlay and preparation method thereof

A modified asphalt, anti-rutting technology, applied in building components, building insulation materials, construction and other directions, can solve the problem of insufficient durability of ultra-thin cover, poor low temperature performance, and reduce the service quality and service life of ultra-thin cover maintenance technology. Promote the scope of application and other issues to achieve the effect of improving service life and service quality, improving high temperature stability, and promoting application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0021] The present invention provides the following technical solutions: a high-viscosity anti-rutting modified asphalt for ultra-thin overlays, waste tire rubber powder pretreatment: take 30 parts by mass of 60-mesh waste rubber powder and 80-mesh waste rubber powder, and mix them Mix well, soak into the KH-550 silane coupling agent solution, place the mixture in an oven at 75°C for 24 hours, then take it out and dry it;

[0022] Preparation of high-viscosity anti-rutting modified asphalt: Take 200 parts by mass of AH-70 base aspha...

PUM

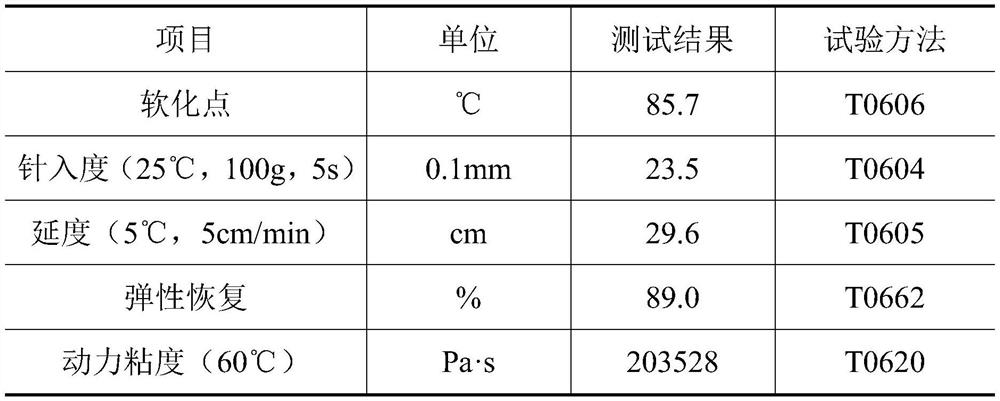

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com