Black fungus oligosaccharide for preventing liver cell oxidative damage as well as preparation method and application thereof

A technology of cell oxidation and fungus oligosaccharide, applied in biochemical equipment and methods, application, digestive system, etc., can solve the problem that ultrasonic-assisted extraction is noisy, cannot meet the large demand for industrial development and production of such products, enzyme preparations high cost issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

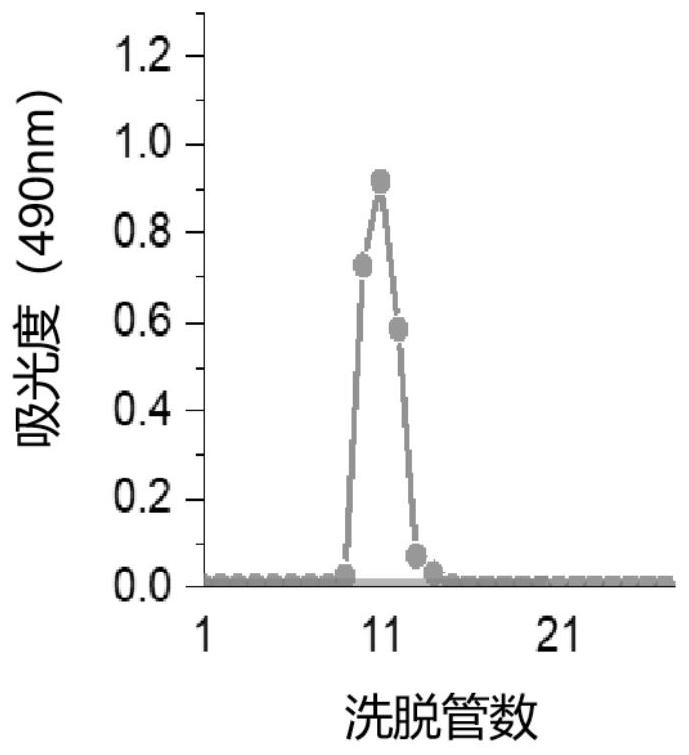

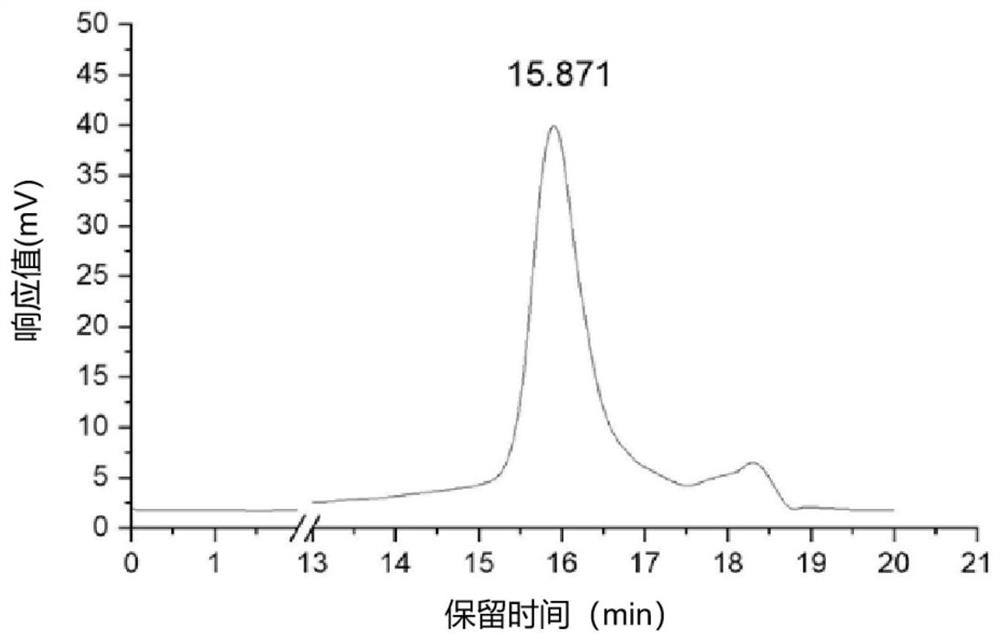

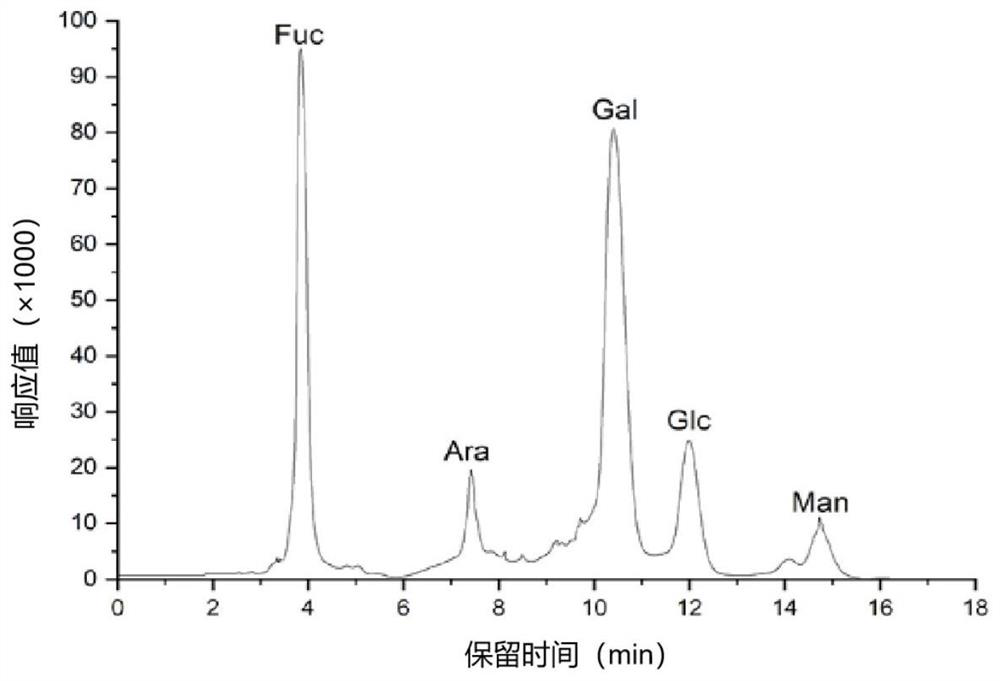

Embodiment 1

[0029] 1. Pulverize the dried fruiting body of black fungus and pass through a 40-mesh sieve to form the dried fruiting body powder of black fungus. The dried fruiting body powder of black fungus is packed into a homogenizer, and deionized water is added according to the ratio of material to liquid at 1:80. Homogenize for 10 minutes, add 10 mg / mL pectinase solution to make the quality of the enzyme 0.4% of the dry fruiting body powder of black fungus, heat and react at a constant temperature in a 50°C water bath for 1 hour, then place the beaker in a 90°C water bath for 1 hour Hours, inactivate pectinase activity, squeeze filter. A single-screw extruder was used for extrusion filtration, the diameter of the die hole of the extruder was 16mm, the temperature of the extruder sleeve was 60°C, and the screw speed was 240r / min. At 90°C, the filtrate of black fungus will be concentrated to 1 / 3 of the original volume, cooled to room temperature, add 3 times the volume of absolute eth...

Embodiment 2

[0033] 1. Pulverize the dried fruiting body of black fungus and pass through a 40-mesh sieve to form the dried fruiting body powder of black fungus. The dried fruiting body powder of black fungus is packed into a homogenizer, and deionized water is added according to the ratio of material to liquid at 1:100. Homogenize for 5 minutes, add 10mg / mL pectinase solution to make the enzyme quality 0.4% of the dried fruit body powder of black fungus, heat and react in a water bath at 50°C for 1 hour, then place the beaker in a water bath at 100°C for 1 hour , inactivate the pectinase activity, and carry out extrusion filtration. A single-screw extruder was used for extrusion filtration, the diameter of the die hole of the extruder was 8mm, the temperature of the extruder sleeve was 80°C, and the screw speed was 160r / min. At 100°C, the filtrate of black fungus will be concentrated to 1 / 2 of the original volume, cooled to room temperature, add 3 times the volume of absolute ethanol, sta...

Embodiment 3

[0037] 1. Pulverize the dried fruiting body of black fungus and pass through a 40-mesh sieve to form the dried fruiting body powder of black fungus. Put the dried fruiting body powder of black fungus into the homogenizer, add deionized water according to the ratio of material to liquid at 1:30, Homogenize for 20 minutes, add 10 mg / mL pectinase solution to make the enzyme quality 0.4% of the dry fruiting body powder of black fungus, heat and react in a water bath at 50°C for 1 hour, then place the beaker in a water bath at 80°C for 1 hour , inactivate the pectinase activity, and carry out extrusion filtration. Extrusion filtration adopts a single-screw extruder, the diameter of the die hole of the extruder is 16mm, the temperature of the extruder sleeve is 100°C, and the screw speed is 260r / min. At 80°C, the black fungus filtrate will be concentrated to 1 / 3 of the original volume, cooled to room temperature, add 4 times the volume of absolute ethanol, stand at 4°C for 12h, 8000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com