Modified polyaspartic acid ester polyurea coating and preparation method thereof

A technology of aspartic acid ester and polyurea, which is applied in the field of coatings and can solve problems such as poor adhesion of substrates and poor flexibility at low temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

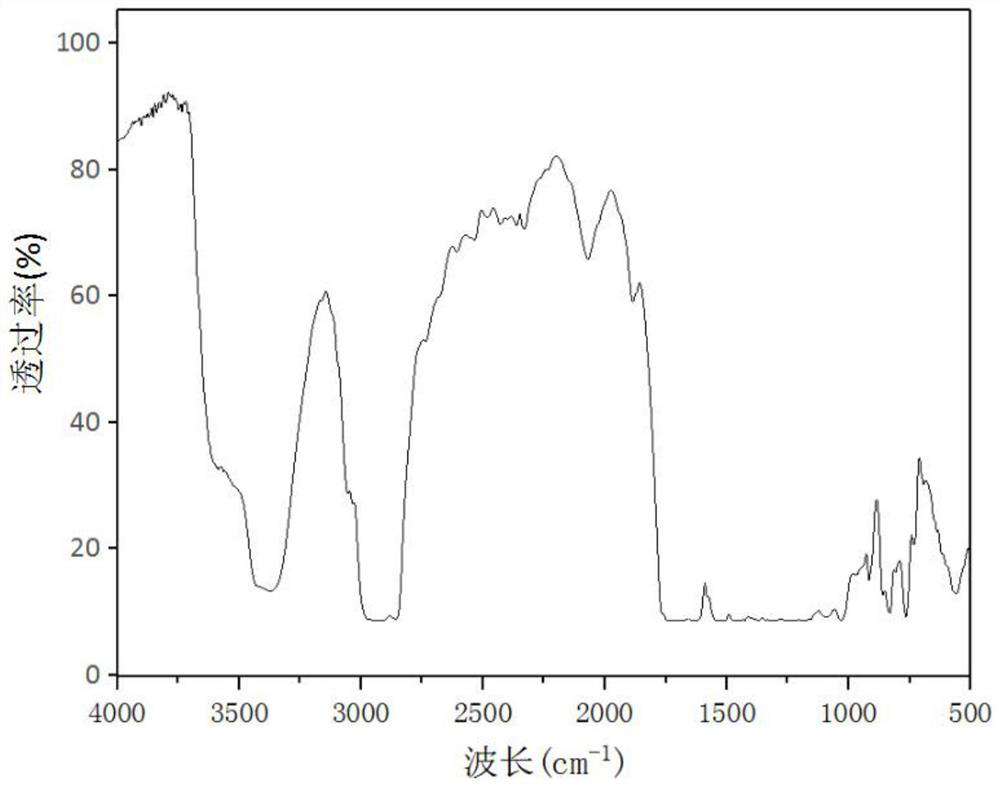

Image

Examples

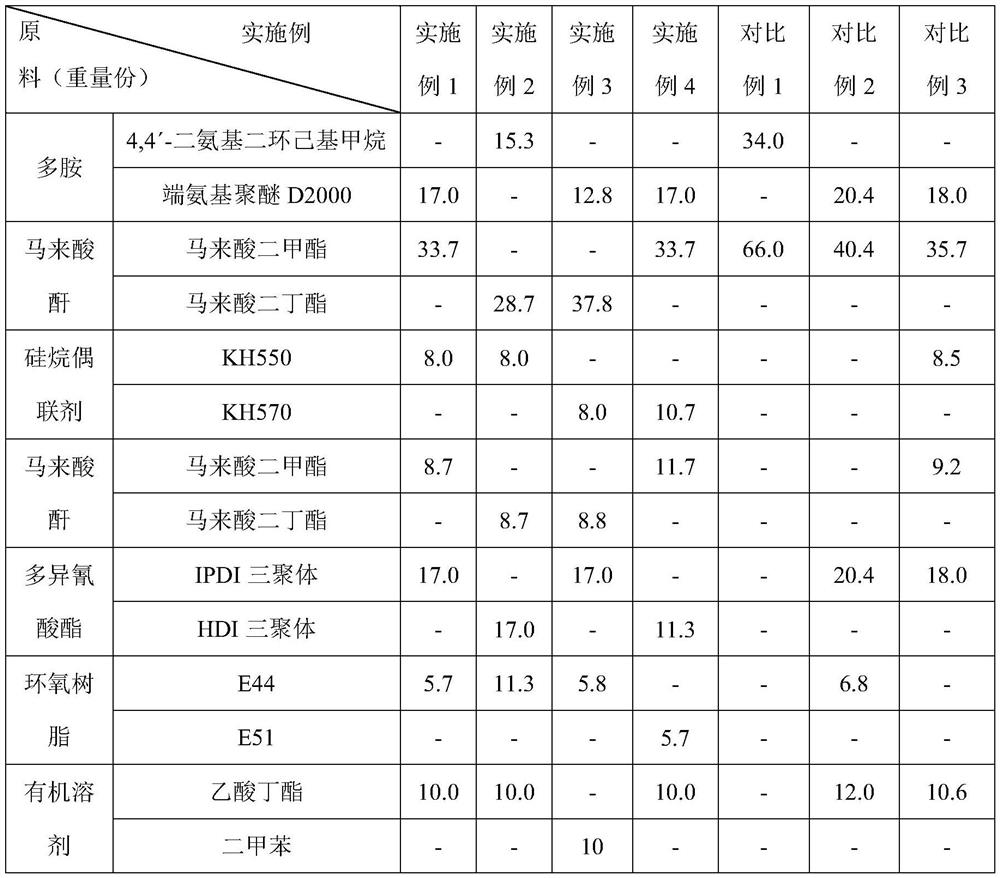

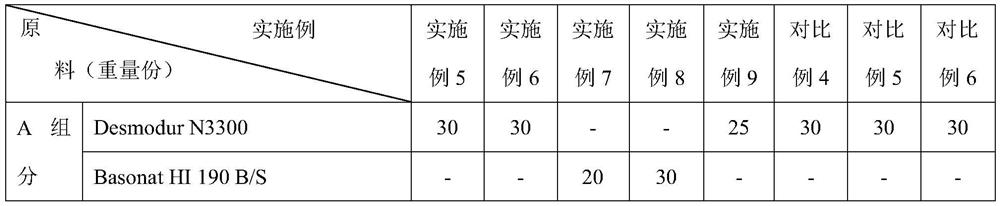

Embodiment 1

[0051] Add 170 parts by weight of amino-terminated polyether D2000 into a reaction kettle with nitrogen gas, stir and heat up to 75°C, add 337 parts by weight of dimethyl maleate dropwise into the reaction kettle, and react at a temperature of 80°C After 16 hours, cool to room temperature to obtain polyaspartic acid ester resin. Add 80 parts by weight of silane coupling agent KH550 and 87 parts by weight of dimethyl maleate into another reaction kettle with nitrogen, stir and heat up to 70°C for 8 hours; then add 170 parts by weight of IPDI trimer and keep warm at 70°C The reaction was carried out for 2 hours, cooled to normal temperature to obtain a prepolymer with -NCO active functional group, which was dissolved in butyl acetate and set aside.

[0052] Add 507 parts by weight of polyaspartic acid ester resin, 57 parts by weight of epoxy resin E44 and 75 parts by weight of butyl acetate into a nitrogen-filled reaction kettle, stir and mix evenly, and add dropwise the solutio...

Embodiment 2

[0055] Add 150 parts by weight of 4,4'-diaminodicyclohexylmethane into the reaction kettle with nitrogen gas, stir and raise the temperature to 75°C, and add 287 parts by weight of dibutyl maleate dropwise to the reaction kettle. After the dropwise addition, React at a temperature of 80° C. for 16 hours, and cool to room temperature to obtain a polyaspartic acid ester resin. Add 80 parts by weight of silane coupling agent KH550 and 87 parts by weight of dibutyl maleate into another nitrogen reactor, stir and raise the temperature to 70°C for 8 hours; then add 170 parts by weight of HDI trimer and keep warm at 70°C The reaction was carried out for 2 hours, cooled to normal temperature to obtain a prepolymer, which was dissolved in butyl acetate and set aside.

[0056] Add 437 parts by weight of polyaspartic acid ester resin, 113 parts by weight of epoxy resin E44 and 75 parts by weight of butyl acetate into a nitrogen-filled reaction kettle, stir and mix evenly, and add dropwis...

Embodiment 3

[0058] Add 128 parts by weight of amino-terminated polyether D2000 into the reaction kettle with argon gas, stir and heat up to 75°C, add 378 parts by weight of dibutyl maleate dropwise into the reaction kettle, after the dropwise addition, at a temperature of 80°C After 16 hours of reaction, polyaspartic acid ester resin was obtained. Add 80 parts by weight of silane coupling agent KH570 and 88 parts by weight of dibutyl maleate into another reaction kettle with argon, stir and raise the temperature to 70°C for 8 hours; then add 170 parts by weight of IPDI trimer and keep it warm for 70 React at ℃ for 2 hours, cool to room temperature to obtain a prepolymer, dissolve the prepolymer in xylene, and set aside.

[0059] Add 506 parts by weight of polyaspartic acid ester resin, 58 parts by weight of epoxy resin E44 and 75 parts by weight of xylene into a reaction kettle with argon gas, stir and mix evenly, and add dropwise in advance dissolved in 25 parts by weight of 338 parts b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com