Passive extrusion type pulse coal chip jet flow coal breaking pressure relief anti-reflection device and use method thereof

An extrusion-type, coal-chipping technology, applied in the fields of fluid extraction, earth-moving drilling, flushing wellbore, etc., can solve problems such as greater safety, hidden dangers, and difficult operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

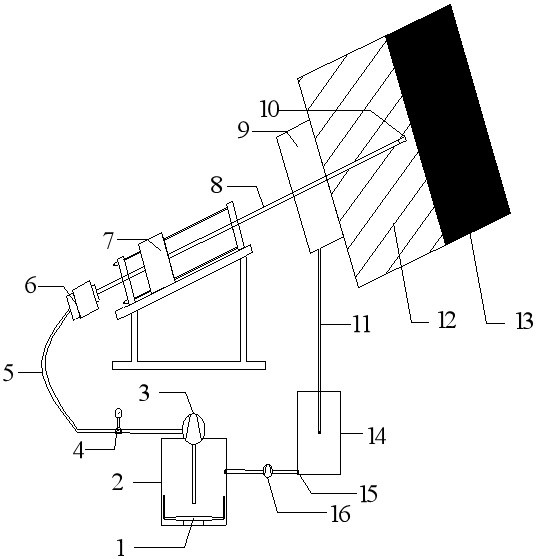

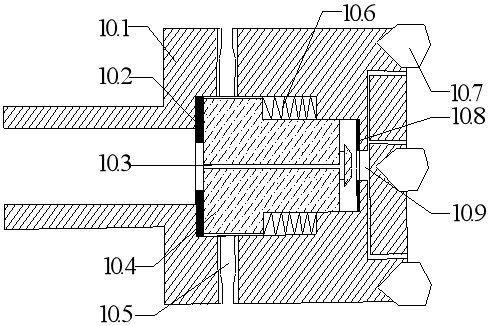

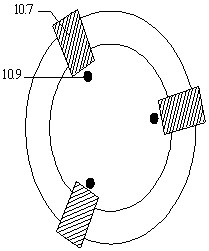

[0028] As shown in the figure, a passive squeeze pulsed coal cuttings jetting coal pressure-relief and permeation enhancement device includes a water tank 2, a mud pump 3 connected to the water tank 2, a high pressure pipeline 5 connected to the outlet of the mud 3, and A drilling rig 7 connected to the outlet of the high-pressure pipeline 5. The drilling rig 7 includes a drill rod 8 and an integrated drill bit 10 located at the end of the drill rod 8. A coal dust box 14 is provided under the integrated drill bit 10. 14 There is a jet pump 16 at the bottom outlet. The outlet of the jet pump 16 is connected to the water tank 2. There is also a rotating water tail between the drilling rig 7 and the high-pressure pipeline 5, and the end of the drill rod 8 is in contact with the rock formation 12. The dust collecting hood 9 is inclined upward, the bottom of the dust collecting hood 9 is provided with a dust collecting pipe 11, and the outlet of the dust collecting pipe 11 is in comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com