A method for extracting high-purity linalool

A linalool, high-purity technology, applied in the field of extracting high-purity linalool, can solve the problems of low product yield and product quality, insufficient resource utilization, poor technical conditions, etc. Benefit and economic benefits, the effect of low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

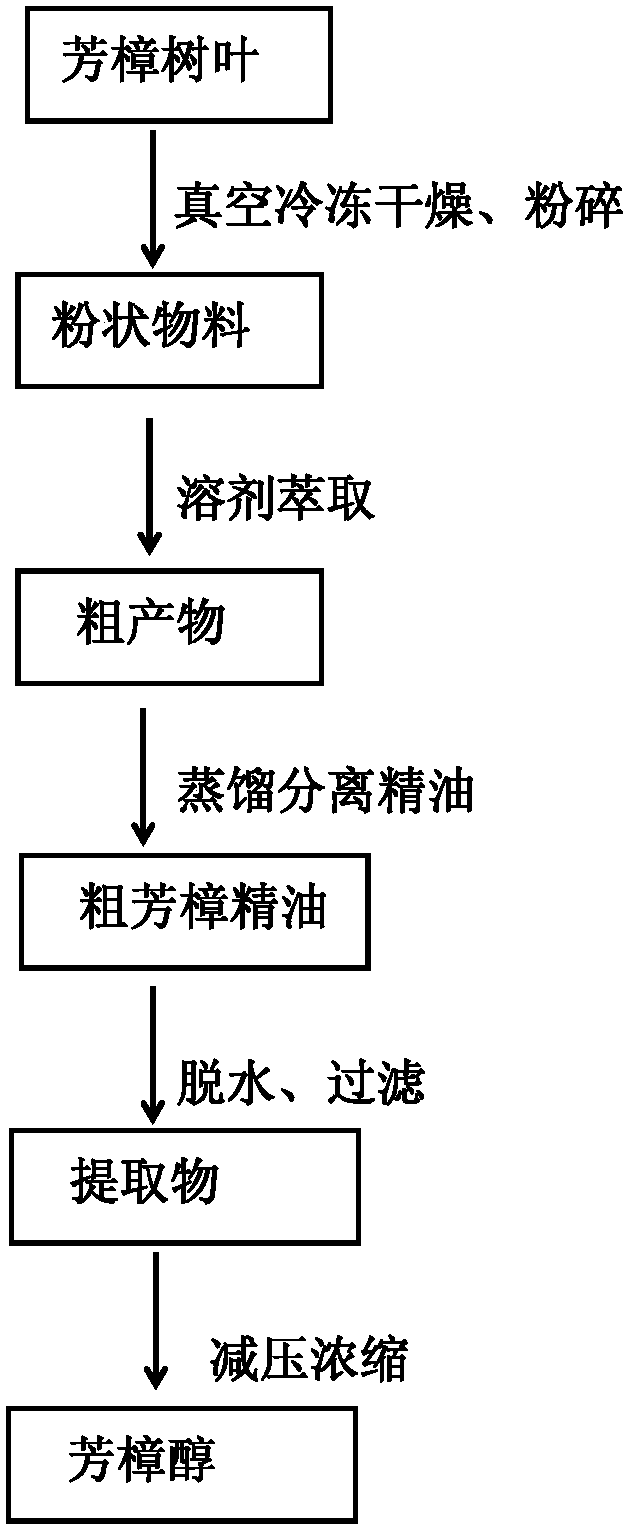

[0029] A method for extracting high-purity linalool, comprising the following steps:

[0030] (1) Raw material pretreatment: Vacuum freeze-dry the fresh leaves of Cinnamomum camphora, crush them to 60 meshes, and obtain powdery materials;

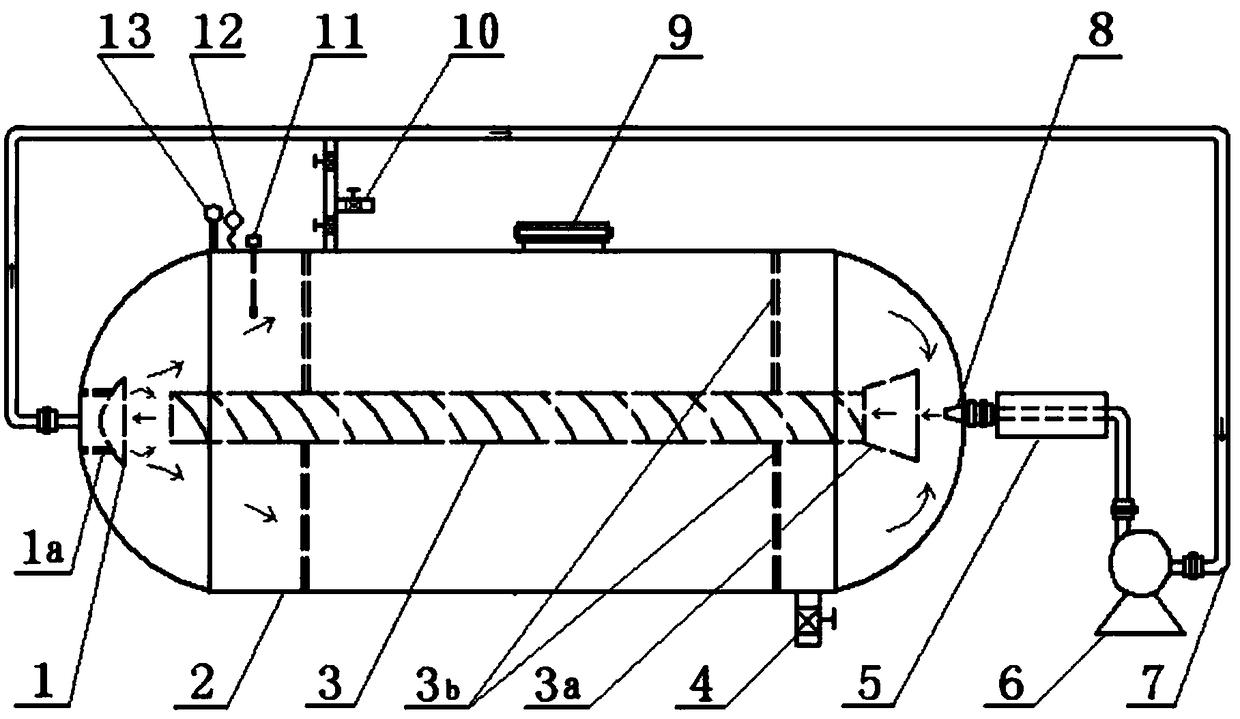

[0031] (2) Solvent extraction: Open the feeding port of the extraction device, add 100kg of powdery material, and then add ethanol and ethyl acetate mixed solvent (ethanol and ethyl acetate The weight ratio is 2:1), cover the feeding port cover, turn on the heater and pump power supply, heat up and cycle extraction, control the temperature at 50 ° C, cycle leaching for 2 hours, discharge the material from the discharge port, and remove the residue after conventional filtration , to get the crude product; the cyclic extraction passes through 6 accelerated leaching mixing zones of pump pressure mixing, nozzle jet mixing, mixing tube mixing, cover reflective mixing, tank flow mixing and pipeline flow mixing to strengthen the leaching of active...

Embodiment 2

[0037] A method for extracting high-purity linalool, comprising the following steps:

[0038] (1) Raw material pretreatment: Vacuum freeze-dry the fresh leaves of Cinnamomum camphora, crush them to 60 meshes, and obtain powdery materials;

[0039] (2) Solvent extraction: Open the feeding port of the extraction device, add 100kg of powdery material, and then add ethanol and ethyl acetate mixed solvent (ethanol and ethyl acetate The weight ratio is 3:1), cover the feeding port cover, turn on the heater and pump power supply, heat up and cycle extraction, control the temperature at 60 ° C, cycle leaching for 1 hour, discharge the material from the discharge port, and remove the residue after conventional filtration , to get the crude product; the cyclic extraction passes through 6 accelerated leaching mixing zones of pump pressure mixing, nozzle jet mixing, mixing tube mixing, cover reflective mixing, tank flow mixing and pipeline flow mixing to strengthen the leaching of active ...

Embodiment 3

[0045] A method for extracting high-purity linalool, comprising the following steps:

[0046](1) Raw material pretreatment: Vacuum freeze-dry the fresh Cinnamomum camphora leaves, crush them to 80 meshes, and obtain powdery materials;

[0047] (2) Solvent extraction: Open the feeding port of the extraction device, add 100kg of powdery material, and then add ethanol and ethyl acetate mixed solvent (ethanol and ethyl acetate The weight ratio is 2:1), cover the feeding port cover, turn on the heater and pump power supply, heat up and cycle extraction, control the temperature at 50°C, cycle leaching for 3 hours, discharge the material from the discharge port, and remove the residue after conventional filtration , to get the crude product; the cyclic extraction passes through 6 accelerated leaching mixing zones of pump pressurization mixing, nozzle jet mixing, mixing tube mixing, cover reflective mixing, tank flow mixing and pipeline flow mixing to strengthen the leaching of active...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com