Preparation method of sulfur composite positive electrode material and all-solid-state lithium-sulfur battery

A composite positive electrode material, lithium-sulfur battery technology, applied in the direction of lithium batteries, positive electrodes, battery electrodes, etc., can solve the problems of large interface impedance, poor solid-solid contact, poor cycle performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing a sulfur composite cathode material for an all-solid-state lithium-sulfur battery, comprising the following steps:

[0028] (1) Uniformly mixing the conductive carbon and the sulfide solid electrolyte by ball milling to obtain mixed conductor powder, wherein the ball milling speed is 100-500 rpm, the ball milling time is 0.5-10 hours, and the ball milling is completed under the protection of an inert atmosphere;

[0029] (2) Screening the mixed conductor powder of step (1) with a sieve to obtain the sieved mixed powder;

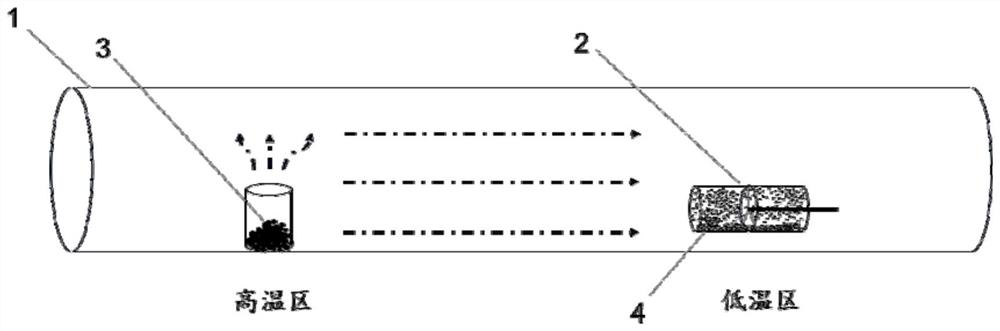

[0030] (3) Place the sulfur element in the high temperature zone of the tube furnace, place the sieved mixed powder obtained in step (2) in the drum sieve in the low temperature zone of the tube furnace, start the high and low temperature zone and roll the drum sieve, and after a certain period of time, the sulfur vapor will Deposited on the mixed powder and cooled to room temperature to obtain a sulfur com...

Embodiment 1

[0037] (1) Preparation of sulfide solid electrolyte Li 6 P.S. 5 Cl

[0038] Weigh 2N pure reagent Li according to the required stoichiometric ratio 2 S, P 2 S 5 After mixing with LiCl, put it into a zirconia ball mill tank, add zirconia balls and mill it at a speed of 300rpm for 6h, and then take out the milled powder and sieve it with a 300-mesh sieve to obtain a uniformly mixed precursor. Place the precursor in the ceramic vibration tank in the microwave equipment and vibrate and turn over, the vibration frequency is 20Hz, the amplitude is 5mm, keep it at 300°C for 10min, and obtain Li 6 P.S. 5 Cl solid electrolyte powder.

[0039] The obtained powder was pressed under a pressure of 200 MPa for 3 minutes to obtain a solid electrolyte sheet. The whole process was carried out under an argon protective atmosphere. The lithium conductivity of the solid electrolyte sheet at room temperature is 3.5×10 -3 Scm -1 .

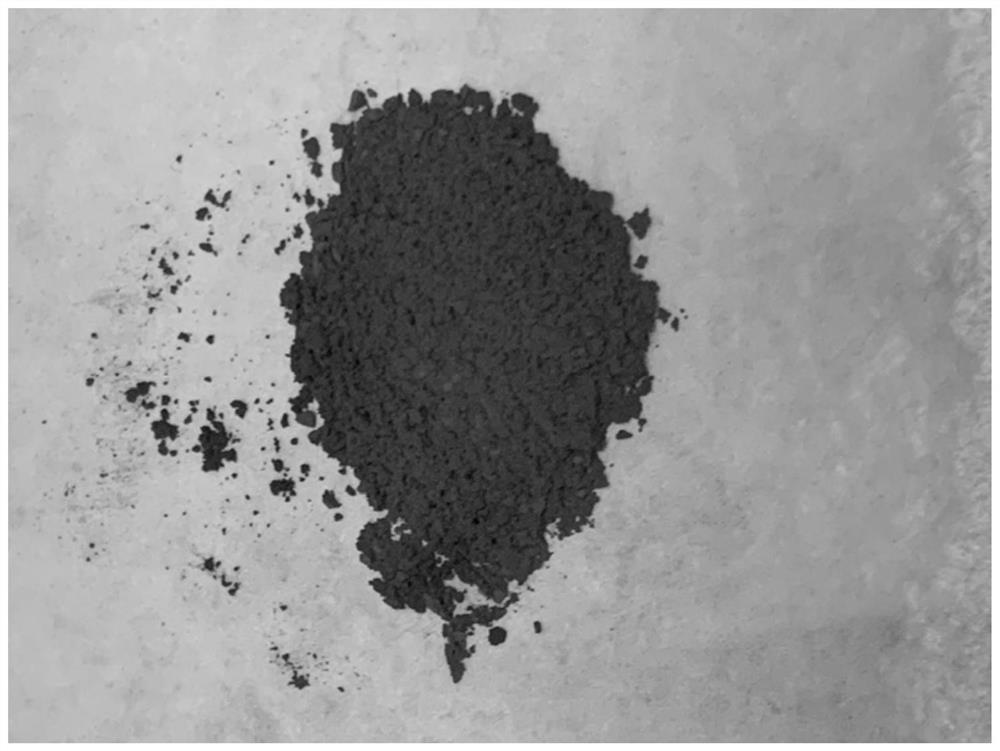

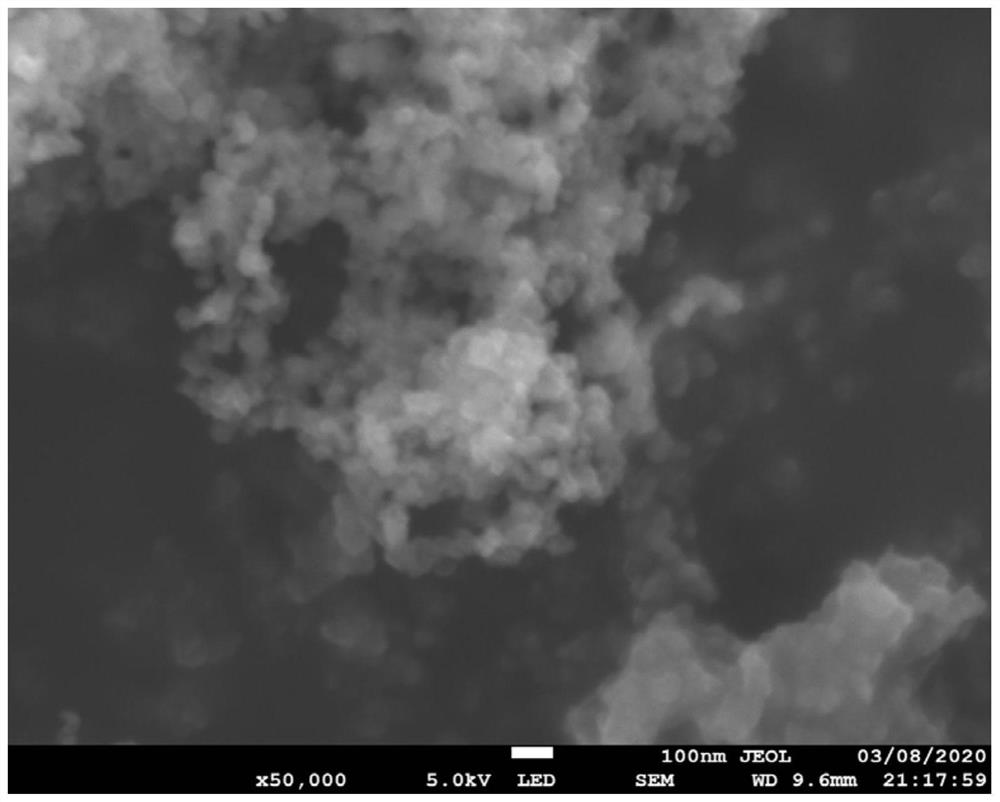

[0040] (2) Preparation of sulfur composite cathode mate...

Embodiment 2

[0045] (1) Preparation of sulfide solid electrolyte Li 6 P.S. 5 Cl

[0046] The Li 6 P.S. 5 The Cl electrolyte was also synthesized by microwave sintering. The preparation method is the same as in Example 1.

[0047] (2) Preparation of sulfur composite cathode materials

[0048] Weigh 55mg carbon nanotubes and 100mgLi respectively 6 P.S. 5 The Cl solid electrolyte was placed in a ball mill jar, and ball milled at 300 rpm for 3 h in an Ar atmosphere. After ball milling, the powder was sieved in a 2000-mesh sieve to obtain a uniformly mixed powder. Then, weigh 1.5g of elemental sulfur and place it in a quartz crucible, and place it in a high-temperature zone; then spread the sieved mixed conductor powder in a drum sieve in a low-temperature zone. The diameter of the drum sieve is 40 mm, and the length is 100 mm. The size is 5000 mesh, and the rotating speed of the trommel screen is 60rpm. The temperature in the high-temperature zone was 350°C, and the temperature in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com