Special-shaped fuel cell gas diffusion layer, preparation method, fuel cell and assembly method

A gas diffusion layer, fuel cell technology, applied in fuel cells, battery electrodes, electrical components, etc., can solve the problems of high contact resistance of bipolar plates, weakened drainage performance, and uneven gas distribution on the surface of the catalytic layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

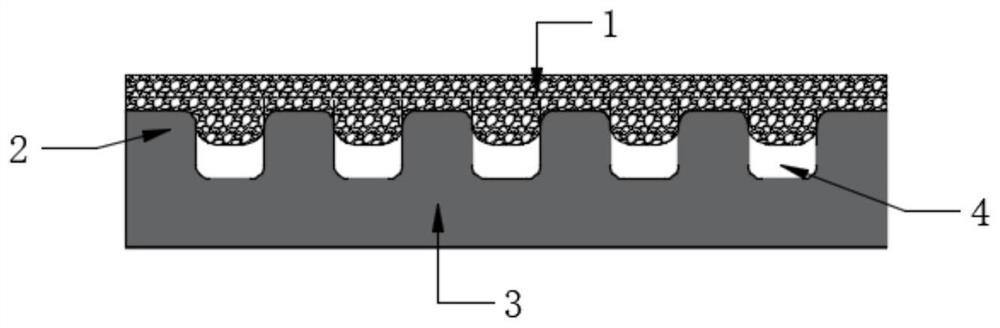

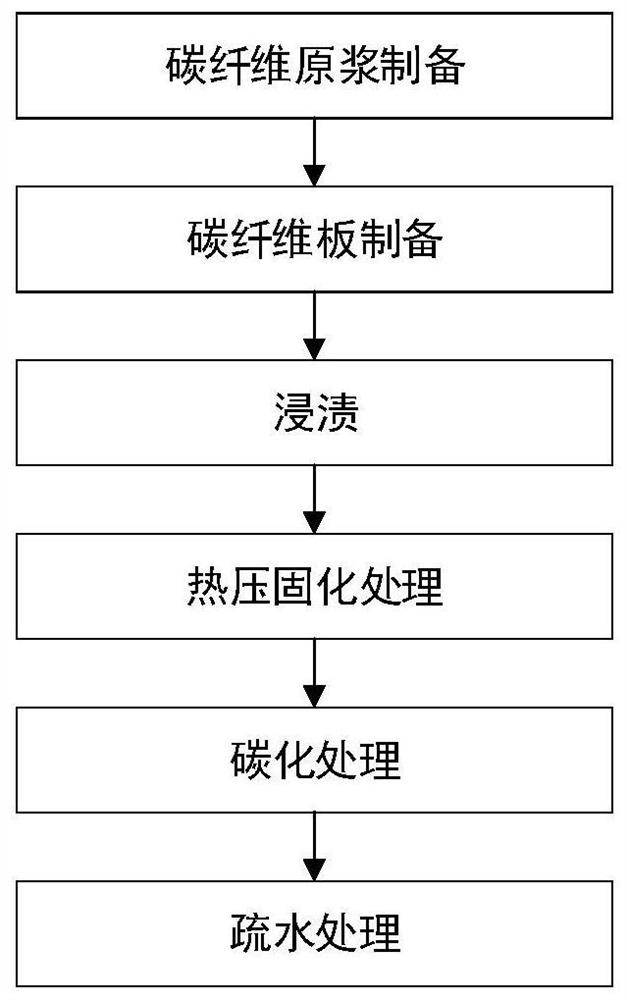

[0064] This embodiment provides a gas diffusion layer for a special-shaped fuel cell (for a schematic diagram, see figure 2 ) and its preparation method.

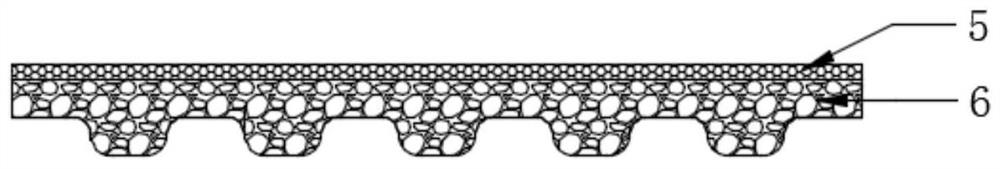

[0065] The heterogeneous fuel cell gas diffusion layer described in this embodiment includes a carbon fiber substrate layer and a microporous layer stacked in sequence, and one side of the carbon fiber substrate layer has continuous and alternately arranged convex parts and concave parts, so that the side surface is convex and concave. Special-shaped structure; the distance m between the convex part and the other side of the carbon fiber substrate layer is the maximum thickness of the carbon fiber substrate layer, and the distance n between the concave part and the other side of the carbon fiber substrate layer is the minimum thickness of the carbon fiber substrate layer, n / m =90%, the maximum thickness of the carbon fiber substrate layer is 200 μm, and the thickness of the microporous layer is 30 μm. The porosity of the ...

Embodiment 2

[0084] This embodiment provides a gas diffusion layer for a special-shaped fuel cell (for a schematic diagram, see figure 2 ) and its preparation method.

[0085] The heterogeneous fuel cell gas diffusion layer described in this embodiment includes a carbon fiber substrate layer and a microporous layer stacked in sequence, and one side of the carbon fiber substrate layer has continuous and alternately arranged convex parts and concave parts, so that the side surface is convex and concave. Special-shaped structure; the distance m between the convex part and the other side of the carbon fiber substrate layer is the maximum thickness of the carbon fiber substrate layer, and the distance n between the concave part and the other side of the carbon fiber substrate layer is the minimum thickness of the carbon fiber substrate layer, n / m =80%, the maximum thickness of the carbon fiber substrate layer is 150 μm, and the thickness of the microporous layer is 100 μm. The porosity of the...

Embodiment 3

[0104] The difference from Example 1 is that n / m=60% in the gas diffusion layer, and the thickness is reduced by 40% in step 4 of the preparation method.

[0105] The compression of the gas diffusion layer in this comparative example is too large, so that the internal pores of the gas diffusion layer and the bipolar plate are smaller after the stack is assembled, and the gas transmission performance and drainage performance of the stack are reduced under high current conditions, which is prone to water flooding. , leading to a decrease in stack performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com