Biodegradable zinc alloy anastomotic apparatus and preparation method thereof

A zinc alloy and device technology, applied in the field of degradable zinc alloy anastomotic devices and its preparation, can solve problems such as allergic reactions, unfavorable tissue observation/inspection, non-degradable titanium alloys, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

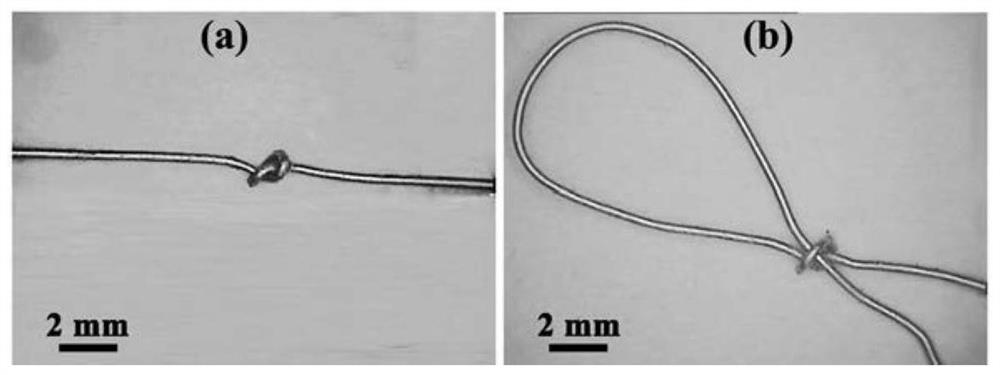

[0046] Select pure Zn (≥99.9wt.%), pure Li (≥99.9wt.%), pure Mn (≥99.9wt.%), pure Y (≥99.9wt.%) as raw materials, and melt in a medium frequency induction furnace . Using CO 2 and SF 6 The mixed gas is used as a protective atmosphere, the raw material is heated to 580° C., the melt is stirred, and the homogenized melt is poured to obtain a Zn-0.8Li-0.1Mn-0.1Y alloy ingot. The ingots were kept at 350°C for 48 hours and then water-cooled. The ingot was preheated to 250°C, the extrusion ratio was controlled to 25, and the extrusion speed was 1mm / s to obtain an extruded Zn-0.8Li-0.1Mn-0.1Y alloy rod with a diameter of 3mm. Subsequently, multiple passes of continuous cold drawing were performed at room temperature, and annealed at 250° C. between passes to finally obtain a Zn-0.8Li-0.1Mn-0.1Y alloy wire with a diameter of 0.3 mm. The degradable Zn-0.8Li-0.1Mn-0.1Y alloy sutures were obtained after the filament was encapsulated and sterilized by Co-60 gamma rays, such as figure...

Embodiment 2

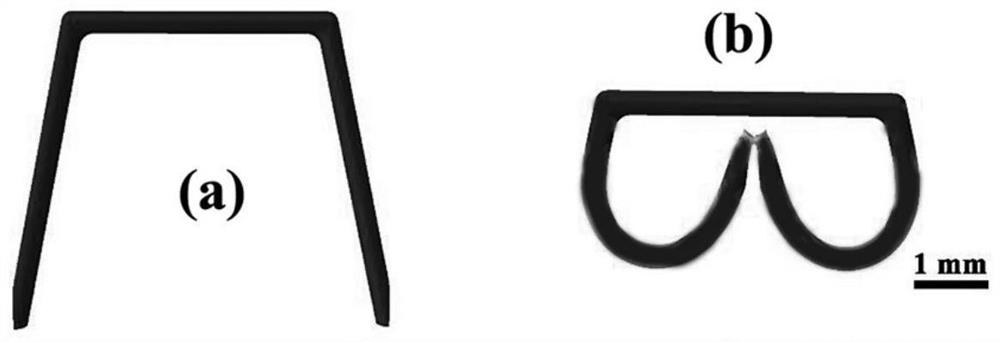

[0048] Select pure Zn (≥99.9wt.%), pure Li (≥99.9wt.%), pure Mn (≥99.9wt.%), pure Y (≥99.9wt.%) as raw materials, and melt in a medium frequency induction furnace . Using CO 2 and SF 6 The mixed gas is used as a protective atmosphere, and the temperature is raised to 500-600° C. to melt the raw materials, and the homogenized melt is poured to obtain a Zn-0.5Li-0.5Mn-0.2Y alloy ingot. The ingots were kept at 350°C for 48 hours and then water-cooled. The ingot was preheated to 250°C, the extrusion ratio was controlled to be 36, and the extrusion speed was 1mm / s to obtain extruded Zn-0.5Li-0.5Mn-0.2Y alloy rods with a diameter of 3mm. Subsequently, the extruded bar was subjected to multiple passes of continuous cold drawing at room temperature, and annealed at 250°C between passes to finally obtain a Zn-0.5Li-0.5Mn-0.2Y alloy wire with a diameter of 0.3mm material. The Zn-0.5Li-0.5Mn-0.2Y alloy wire is bent into a U shape on a special mold, and the degradable Zn-0.5Li-0.5Mn-...

Embodiment 3

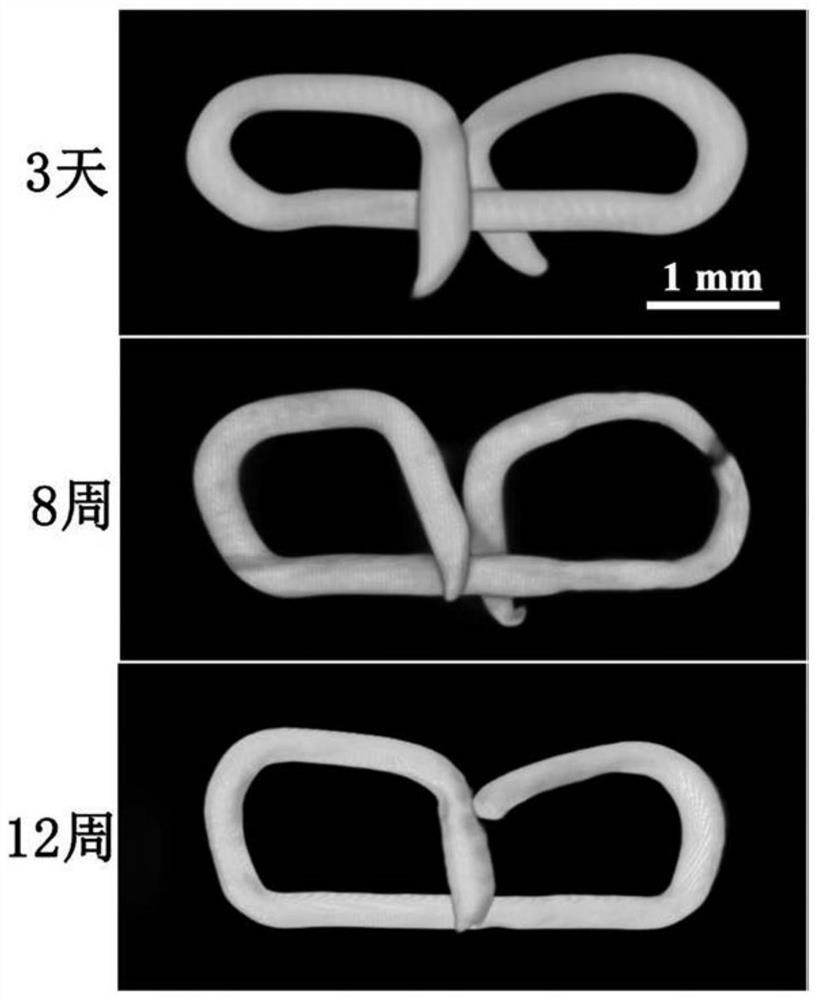

[0051] According to the method described in Example 1 and Example 2, a Zn-0.4Li-0.2Mn-0.1Y alloy ingot was obtained, and the ingot was kept at 350° C. for 48 hours and then cooled by water quenching. The ingot is machined to obtain a hollow cylindrical tube blank. The tube blank is subjected to multi-pass drawing treatment at 200-300°C, and annealed at 250°C between passes, and finally a hollow Zn-0.4Li-0.2 with a diameter of Figure 4 As shown, the staple is composed of a U-shaped Zn-0.4Li-0.2Mn-0.1Y alloy hollow nail 1, an active drug 2 filled in the hollow nail and a release channel 3 for the active drug. constitute. Under the action of the body fluid, the active drug can be released into the surrounding tissue through the two ends of the U-shaped staple to achieve a corresponding therapeutic effect. The drug-loaded Zn-0.4Li-0.2Mn-0.1Y alloy staple has firm anastomosis, uniform corrosion in tissues or organs, high tissue compatibility, and can avoid anastomosis-related comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com