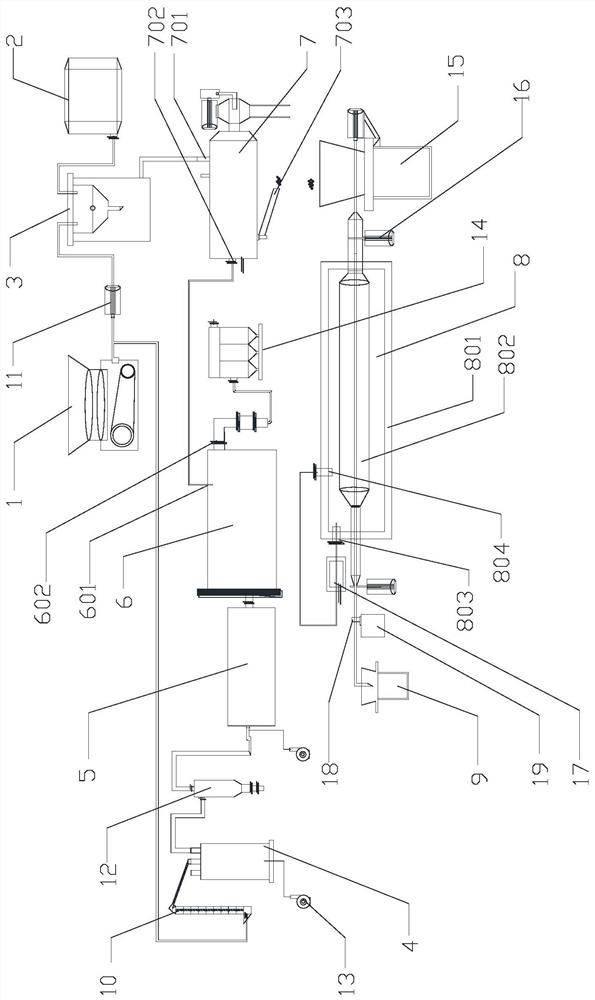

Municipal sludge and garden waste synergistic resource treatment method and system

A technology for garden waste and municipal sludge, which is applied in the field of collaborative resource disposal of municipal sludge and garden waste, can solve problems such as waste, energy consumption reduction, and high disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method of using the above-mentioned system for collaborative resource disposal of municipal sludge and garden waste, comprising the following steps:

[0046] (1) Pretreatment: The garden waste is crushed by the garden waste crusher, and the municipal sludge is dried for the first time by the filter press; the particle size of the crushed garden waste is 15mm, and the first drying The moisture content of the sludge after sludge is 60%;

[0047] (2) Mixed drying: Mix the partially crushed garden waste with the municipal sludge after the first drying in the mixing bin to form a mixed sludge, and the mixed sludge enters the steam dryer for the second drying Obtain mixed granular sludge; the mass fraction of garden waste in the mixed sludge is 20%, and the moisture content of the mixed granular sludge after drying for the second time is 30%;

[0048] (3) Dry distillation of mixed granular sludge: dry distillation of mixed granular sludge under anaerobic conditions by a dr...

Embodiment 2

[0051] A method of using the above-mentioned system for collaborative resource disposal of municipal sludge and garden waste, comprising the following steps:

[0052] (1) Pretreatment: The garden waste is crushed by the garden waste crusher, and the municipal sludge is dried for the first time by the filter press; the particle size of the crushed garden waste is 15mm, and the first drying The moisture content of the sludge after sludge is 60%;

[0053] (2) Mixing and drying: Mix the partially crushed garden waste and the municipal sludge after the first drying in the mixing bin to form a mixed sludge, and add CuCl to the mixing bin during mixing 2 , FeCl 2 and FeCl 3 The mixed solution, Cu in the mixed solution 2+ The concentration is 1.8mol / L, Fe 2+ The concentration of Fe is 0.7mol / L, Fe 3+ The concentration of the mixed sludge is 0.9mol / L, and the mass volume ratio of the mixed sludge to the mixed solution is 100g:15mL; the obtained mixed sludge enters the steam dryer ...

Embodiment 3

[0057] A method of using the above-mentioned system for collaborative resource disposal of municipal sludge and garden waste, comprising the following steps:

[0058] (1) Pretreatment: The garden waste is crushed by a garden waste crusher, and the municipal sludge is dried for the first time by a filter press; the particle size of the crushed garden waste is 10mm, and the first drying The moisture content of the sludge after melting is 58%;

[0059] (2) Mixing and drying: Mix the partially crushed garden waste and the municipal sludge after the first drying in the mixing bin to form a mixed sludge, and add CuCl to the mixing bin during mixing 2 , FeCl 2 and FeCl 3 The mixed solution, Cu in the mixed solution 2+ The concentration is 2mol / L, Fe 2+ The concentration is 1mol / L, Fe 3+ The concentration of the mixed sludge is 1mol / L, and the mass volume ratio of the mixed sludge to the mixed solution is 100g:10mL; the obtained mixed sludge enters the steam dryer for the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com