Preparation method of composite prefabricated part lining for high-temperature lime rotary kiln

A technology of lime rotary kiln and prefabricated parts, which is applied in lime production, rotary drum furnace, lighting and heating equipment, etc. It can solve the problems of low flushing service life, high-temperature lime rotary kiln lining is not resistant to erosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A method for preparing a composite prefabricated liner for a high-temperature lime rotary kiln according to the present invention comprises the following steps:

[0056] (1) Weigh and prepare raw materials;

[0057] (2) Classify the prepared raw materials and put them into the material pulverizer, crush the materials to the required particle size according to the requirements, and then mix evenly, add water accounting for 4-6wt% of the total weight of the raw materials, and grind at room temperature 5-25 degrees Celsius Stir evenly in the environment;

[0058] (3) pour the mixed material mixed with water into the model to obtain the billet;

[0059] (4) Bake the blank at low temperature until it is shaped;

[0060] Wherein, the raw material described in the step (1) comprises the following components according to the parts by mass:

[0061] 10-20 parts of alumina-based magnesium-aluminum spinel particles with a particle size of 10-5 mm;

[0062] 10-20 parts of alumi...

Embodiment 2

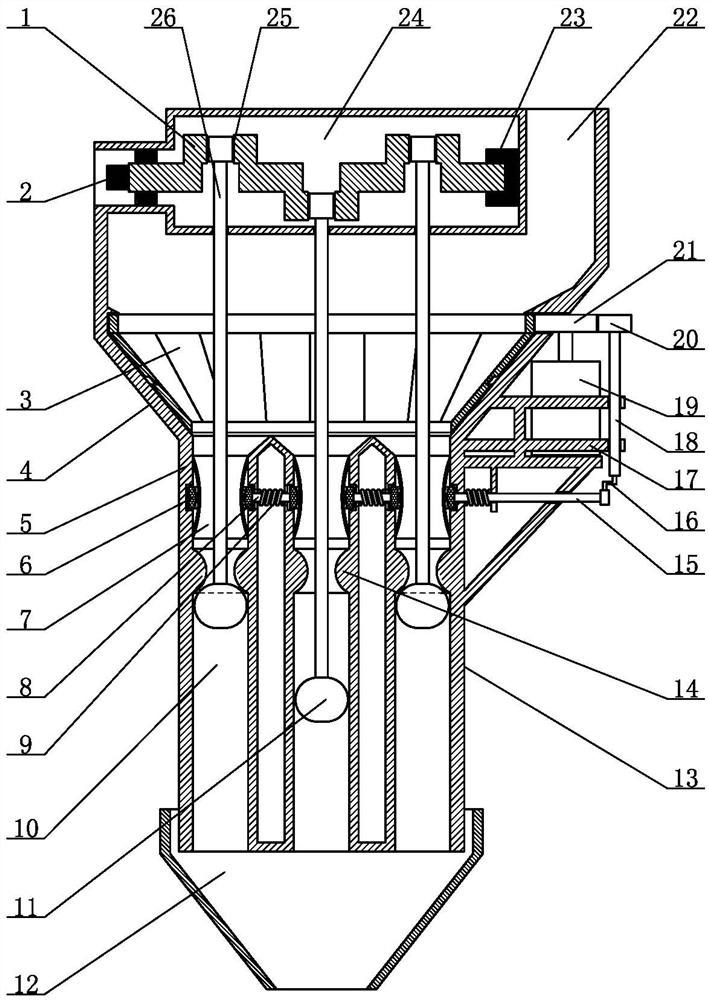

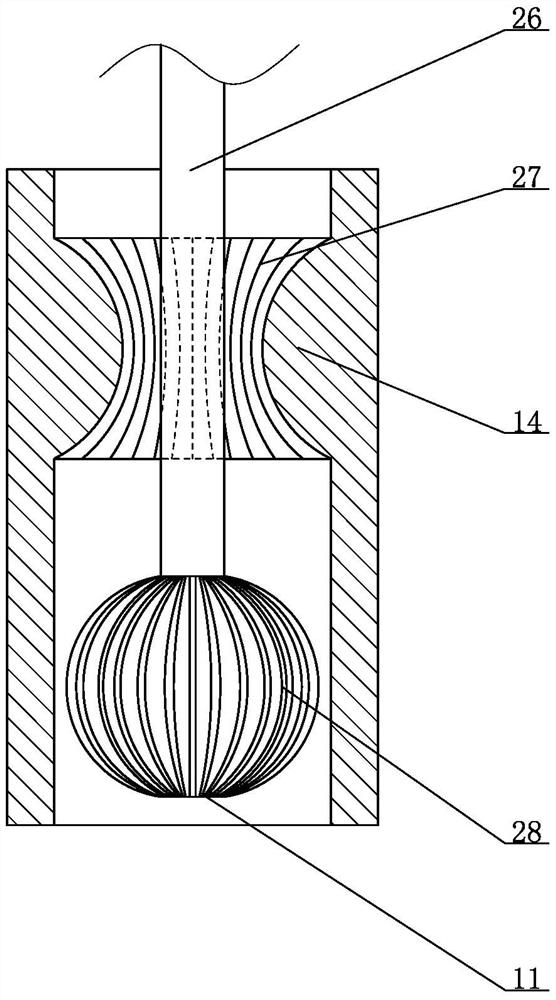

[0096] Such as figure 1 with 2 As shown, in this embodiment, the material pulverizer includes a grinding outer casing, and the grinding outer casing includes an upper material shell, an input material shell, a grinding material shell and a discharge shell, and the upper material shell , the feeding shell, the milling shell and the discharging shell are connected together from top to bottom in order, and the main cavity and the auxiliary cavity are arranged in the feeding shell, and the crankshaft is arranged horizontally in the main cavity, and the front end shaft of the crankshaft passes through the bearing seat Installed on the side wall of the main cavity, the rear end shaft of the crankshaft is connected to the crankshaft drive motor, and the crankshaft drive motor is fixed on the side wall of the other side of the main cavity; the crankshaft includes at least three connecting rod journals ; The auxiliary cavity communicates with the feed shell; the feed shell is in the s...

Embodiment 3

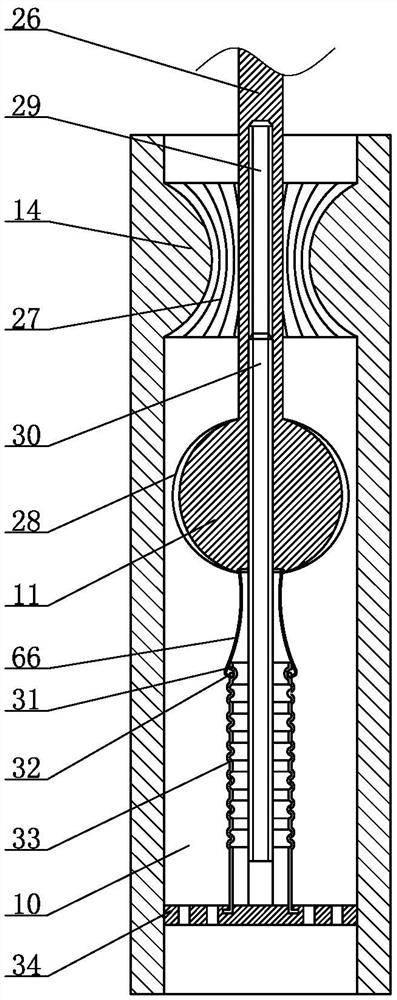

[0105] Such as image 3As shown, the material pulverizer also includes a grinding ball rotation driving device, which is arranged below the grinding balls in the grinding material sub-chamber; the grinding connecting rod includes an upper connecting rod body and a lower connecting rod body , the upper connecting rod body and the lower connecting rod body are coaxially rotatably connected, and the lower end of the lower connecting rod body is fixedly connected with the grinding ball as a whole; a strip-shaped screw hole is set upward from the bottom of the grinding ball, and the strip-shaped screw hole is upward It extends into the lower connecting rod body; the grinding ball rotation driving device includes a fixed sieve plate, which is horizontally fixed below the grinding material sub-chamber, and sieve holes are set on the fixed sieve plate; the upper center of the fixed sieve plate Vertically fix the rotating driving screw shaft, the upper end of the rotating driving screw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com