Method for rapidly preparing two-dimensional covalent organic framework material at low temperature and two-dimensional covalent organic framework material

A covalent organic framework, room temperature technology, applied in the field of two-dimensional covalent organic framework materials, low-temperature rapid preparation of two-dimensional covalent organic framework materials, can solve complex operation process, high reaction temperature, long reaction time and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

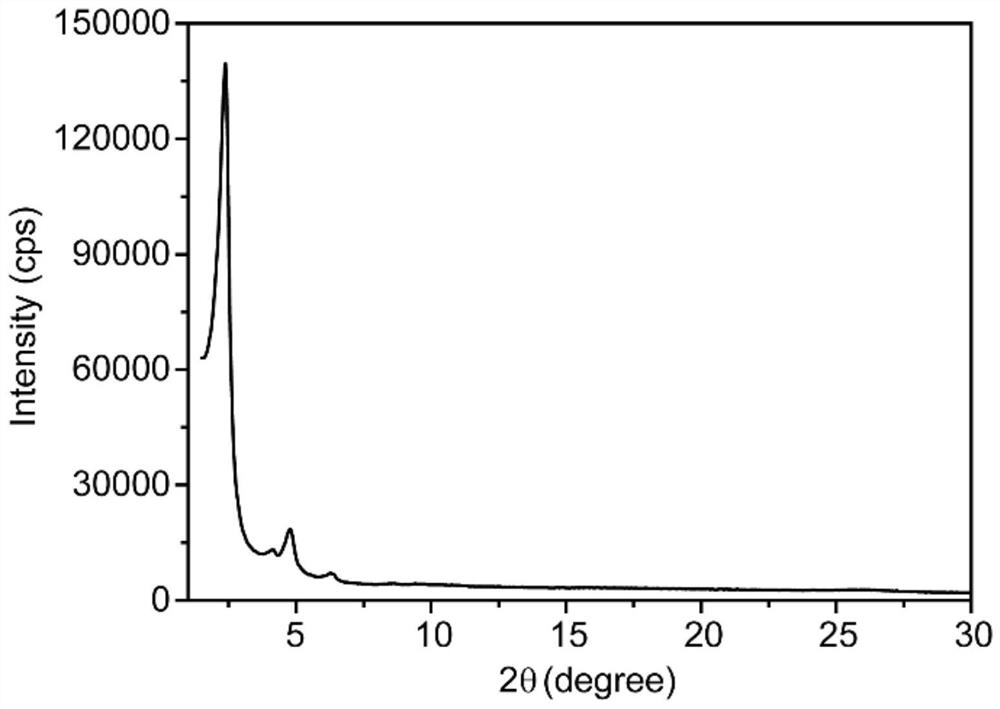

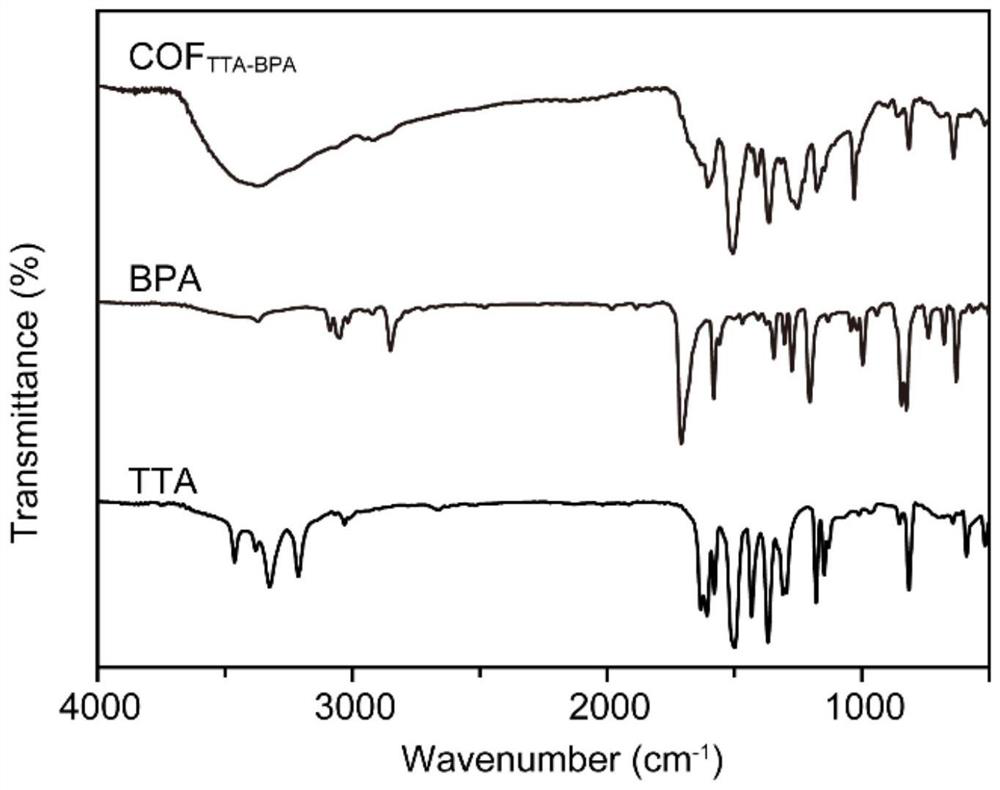

Embodiment 1

[0043] This example provides a method for rapidly preparing a two-dimensional covalent organic framework material at low temperature, as follows.

[0044] Step 1: In the reaction vessel, sequentially add 1 mL of dioxane and mesitylene with a volume ratio of 4:1 mixed solvent, 0.08 mmol 4,4',4"-(1,3,5-triazine-2 ,4,6-triyl)trianiline (4,4',4"-(1,3,5-triazine-2,4,6-triyl)trianiline, TTA) and 0.12 mmol 3,3'-bipyridine -6,6'-dicarbaldehyde ([3,3'-bipyridine]-6,6'-dicarbaldehyde, BPA), ultrasonically dispersed to obtain a mixed solution 1. Wherein, the reaction container may be a glass vessel with a lid. Specifically, the ultrasonic dispersion can be 60W for 10 seconds.

[0045] Step 2: Add 0.08 mmol of Lewis acid and 0.4 mL of acetic acid solution with a concentration of 6 mol / L into the mixed solution 1, and disperse uniformly by ultrasonic to obtain the mixed solution 2. Specifically, the ultrasonic dispersion can be 60W for 5 seconds.

[0046] Step 3: Seal the reaction vess...

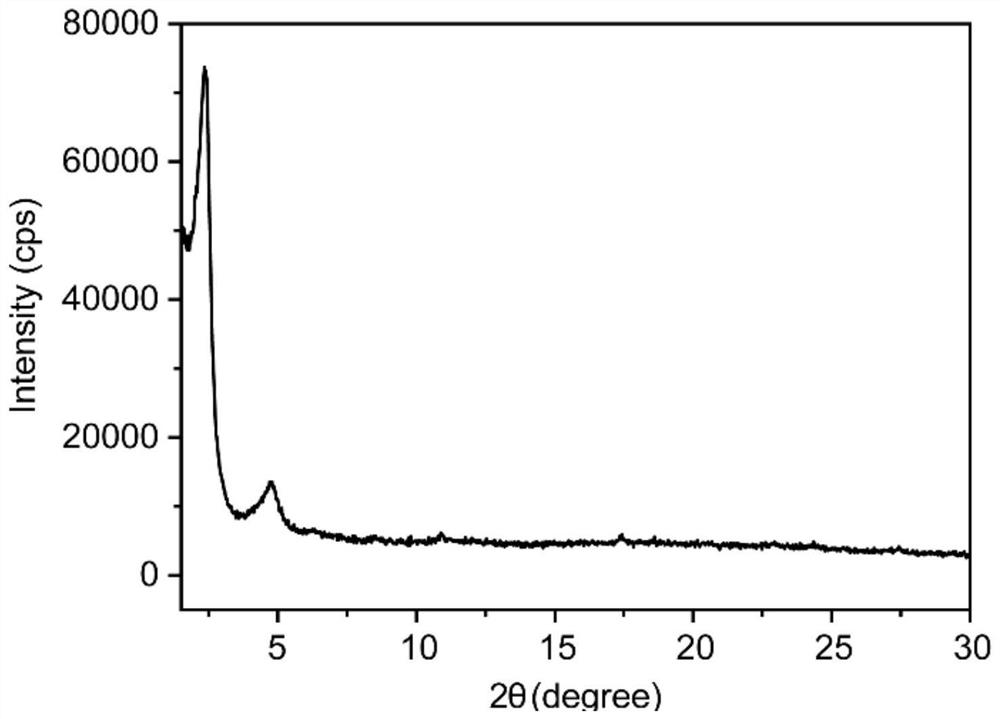

Embodiment 2

[0055] This example provides a method for rapidly preparing a two-dimensional covalent organic framework material at low temperature, as follows.

[0056] Step 1: In the reaction vessel, sequentially add 1 mL of dioxane and mesitylene with a volume ratio of 4:1 mixed solvent, 0.08 mmol of 1,3,5-tris(4-aminophenyl)benzene (1,3, 5-tris(4-aminophenyl)benzene, TAPB) and 0.12mmol 3,3'-bipyridine-6,6'-dicarbaldehyde (BPA) were dispersed uniformly by ultrasonic to obtain a mixed solution 1.

[0057] Step 2: Add 0.08 mmol of Lewis acid and 0.4 mL of acetic acid solution with a concentration of 6 mol / L into the mixed solution 1, and disperse uniformly by ultrasonic to obtain the mixed solution 2.

[0058] Step 3: Seal the reaction vessel containing the mixed solution 2 at normal temperature and pressure, or seal it under vacuum after quick freezing with liquid nitrogen.

[0059] Step 4: Reacting the closed reaction vessel at a relatively low temperature (0-25° C.) for 1-30 minutes to ...

Embodiment 3

[0067] This example provides a method for rapidly preparing a two-dimensional covalent organic framework material at low temperature, as follows.

[0068] Step 1: In the reaction vessel, sequentially add 1 mL of dioxane and mesitylene with a volume ratio of 4:1 mixed solvent, 0.08 mmol 4,4',4"-(1,3,5-triazine-2, 4,6-triyl)triphenylamine (TTA) and 0.12 mmol 2,5-dicarboxyphenazine (pyrazine-2,5-dicarbaldehyde, PDA) were dispersed uniformly by ultrasonic to obtain a mixed solution 1.

[0069] Step 2: Add 0.08 mmol of Lewis acid and 0.4 mL of acetic acid solution with a concentration of 6 mol / L into the mixed solution 1, and disperse uniformly by ultrasonic to obtain the mixed solution 2.

[0070] Step 3: Seal the glass reaction container containing the mixed solution 2 at normal temperature and pressure, or seal it under vacuum after quick freezing with liquid nitrogen.

[0071] Step 4: Reacting the closed reaction vessel at a relatively low temperature (0-25° C.) for 1-30 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com