Antibacterial laundry condensate bead and preparation method thereof

A technology of laundry coagulation beads and antibacterial agents, which is applied in the field of daily chemical detergents and can solve problems such as decreased activity, easy oxidative denaturation, and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

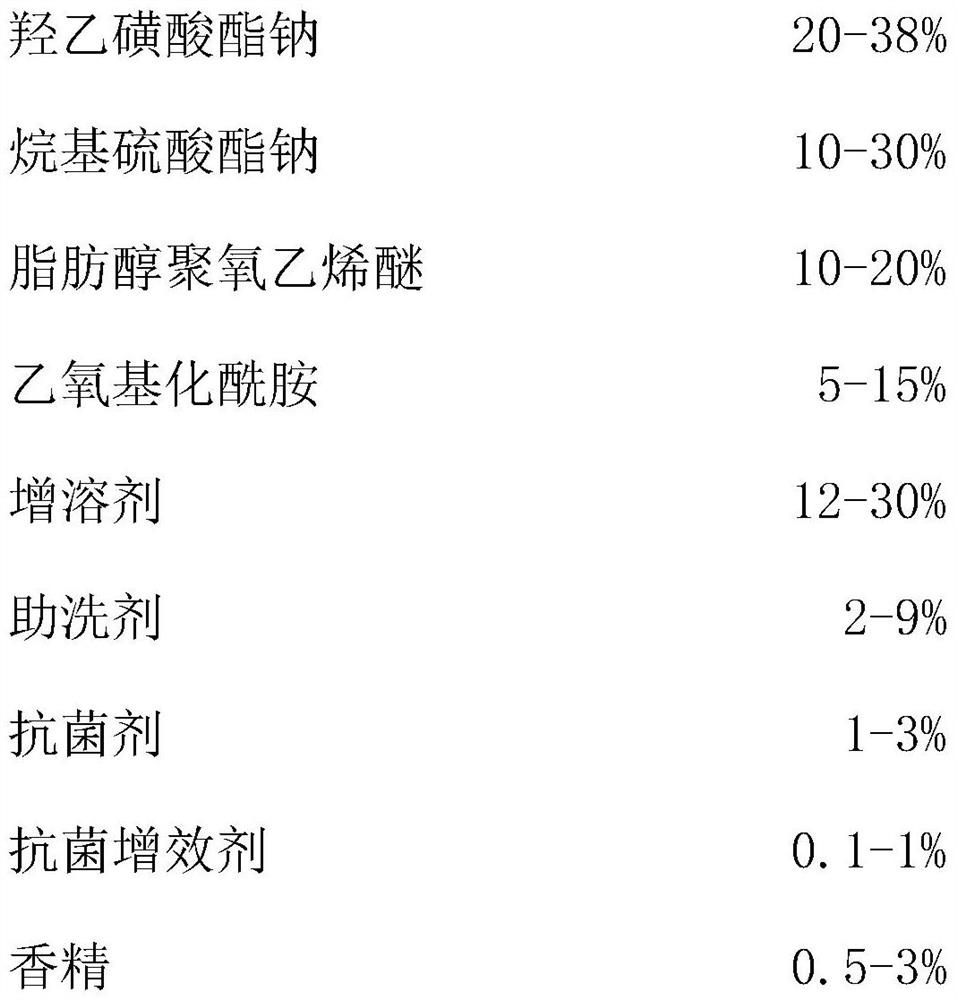

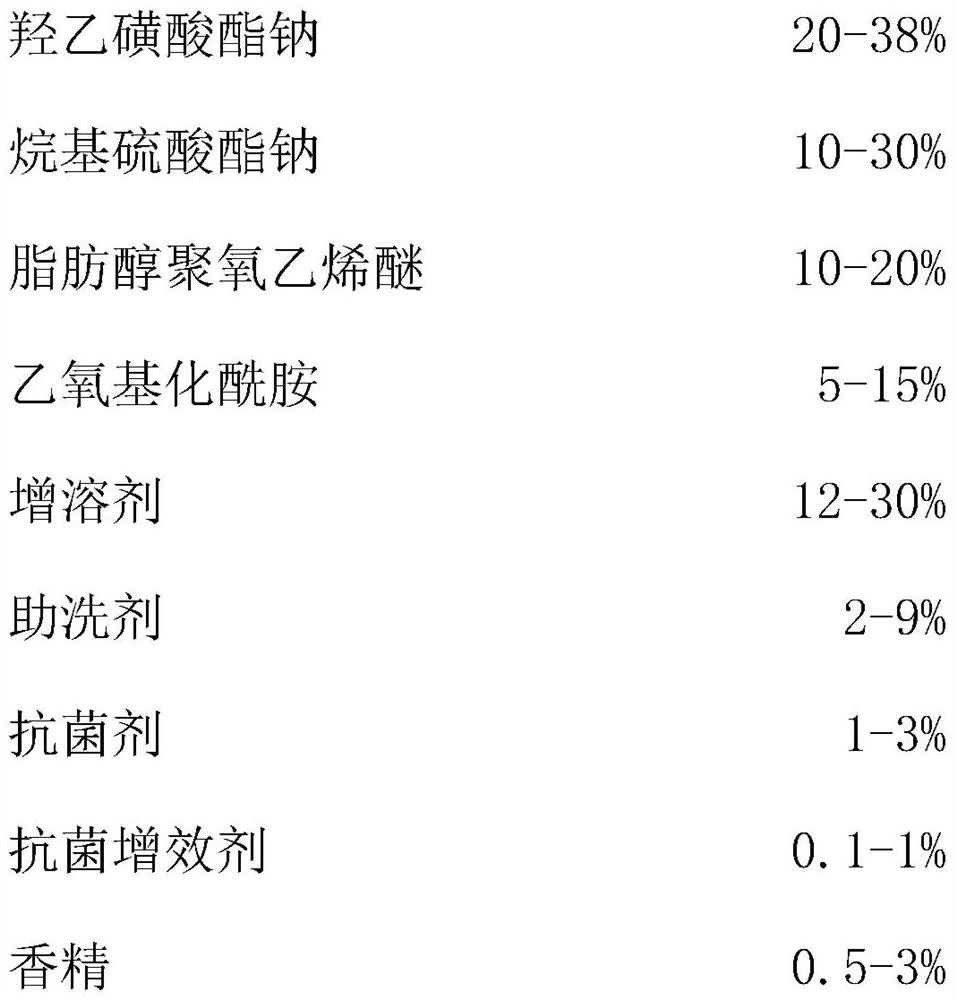

[0024] An antibacterial laundry gel beads, comprising the following components by mass percentage:

[0025] Sodium Cocoyl Isethionate 20%, Sodium Lauryl Sulfate 28%, Fatty Alcohol Ethoxylates AEO-9 20%, Ethoxylated Alkanolamides 5%, Propylene Glycol 14%, Sodium Citrate 9 %, JewelSilver II silver ion antibacterial agent (produced by Japan JTS Co., Ltd.) 3%, hydrogen peroxide (concentration 30%) 0.2%, essence 0.8%.

[0026] A preparation method for antibacterial laundry beads, comprising the following steps:

[0027] (1) take each raw material according to mass percentage;

[0028] (2) Add propylene glycol to the reaction kettle, heat up to 55°C, then add sodium cocoyl isethionate and sodium lauryl sulfate, and turn on the stirring paddle to stir and dissolve at a stirring speed of 400r / min; After dissolving, add fatty alcohol polyoxyethylene ether AEO-9, ethoxylated alkanolamide, add sodium citrate after dissolving, stir until completely dissolved, then cool to room temperatu...

Embodiment 2

[0031] An antibacterial laundry gel beads, comprising the following components by mass percentage:

[0032] Sodium Lauroyl Isethionate 28%, Sodium Lauryl Sulfate 18%, Fatty Alcohol Polyoxyethylene Ether AEO-9

[0033] 15%, ethoxylated alkanolamide 13%, glycerol 18%, sodium citrate 4%, JewelSilver II silver ion antibacterial agent (produced by Japan JTS Co., Ltd.) 1.5%, hydrogen peroxide (concentration 30%) 0.5% , Flavor 2%.

[0034] A preparation method for antibacterial laundry beads, comprising the following steps:

[0035] (1) take each raw material according to mass percentage;

[0036] (2) Add glycerol to the reaction kettle, heat up to 60°C, then add sodium lauroyl isethionate and sodium lauryl sulfate, and turn on the stirring paddle to stir and dissolve at a stirring speed of 420r / min; After dissolving, add fatty alcohol polyoxyethylene ether AEO-9, ethoxylated alkanolamide, add sodium citrate after dissolving, stir until completely dissolved, then cool to room temp...

Embodiment 3

[0039] An antibacterial laundry gel beads, comprising the following components by mass percentage:

[0040]Sodium Coco Isethionate 37%, Sodium Lauryl Sulfate 10%, Fatty Alcohol Ethoxylates AEO-9 10%, Ethoxylated Alkanolamides 10%, Sodium Xylene Sulfonate 28%, Lemon sodium nitrate 2.5%, DM930 silver ion antibacterial agent (produced by Guangdong Dimei Biotechnology Co., Ltd.) 1%, hydrogen peroxide (concentration 30%) 1%, essence 0.5%.

[0041] A preparation method for antibacterial laundry beads, comprising the following steps:

[0042] (1) take each raw material according to mass percentage;

[0043] (2) Add sodium xylene sulfonate to the reaction kettle, heat up to 65°C, then add sodium coconut oil isethionate and sodium lauryl sulfate, and turn on the stirring paddle to stir and dissolve, the stirring speed is 450r / min After being completely dissolved, add fatty alcohol polyoxyethylene ether AEO-9, ethoxylated alkanolamide, add sodium citrate after dissolving, stir until c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com