High-strength roadbed structure and construction method

A construction method and high-strength technology, applied in the direction of roads, roads, road repair, etc., can solve problems such as shortening the life of highways

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

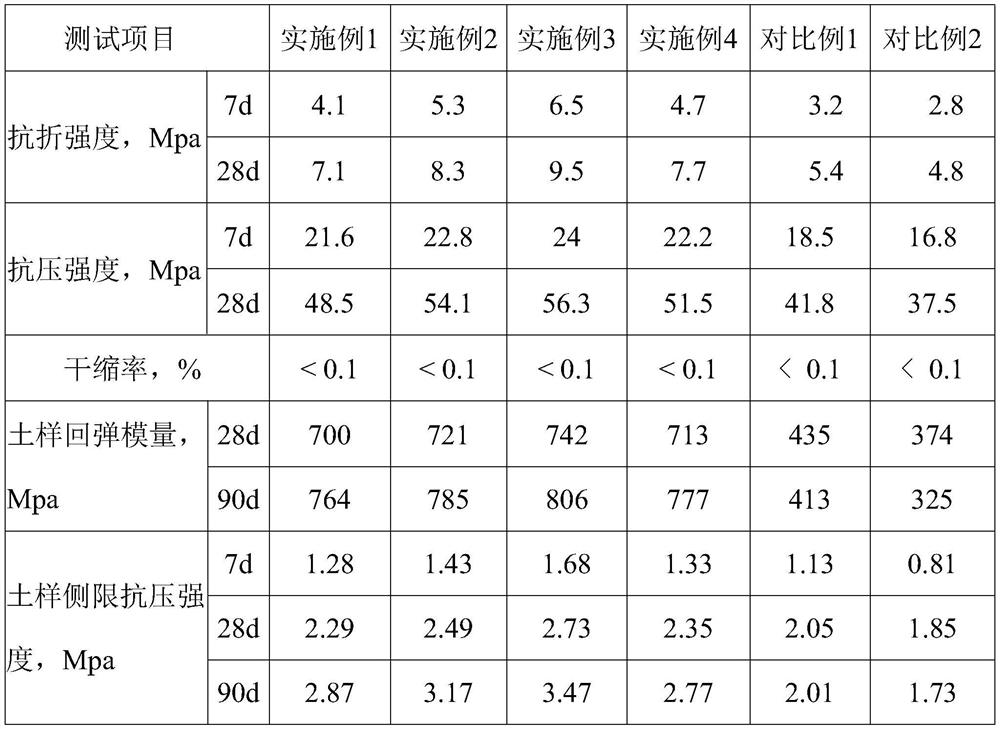

Examples

Embodiment 1

[0024] The high-strength subgrade of the present invention is obtained by following steps of construction:

[0025] S1. Excavate and level the original foundation to ensure that the surface of the foundation is flat and the slope is uniform;

[0026] S2. Spread the undisturbed soil on the foundation in three layers. The virtual paving thickness of each layer is 22cm, 22cm, and 21 cm respectively, and measure the water content of the undisturbed soil. If the optimal water content of the mixture is 14.5% +6 The high-strength consolidating agent can be paved in the range of %~-1%. Spread the high-strength consolidating agent evenly, and use a road mixer to mix the improved soil evenly. The working speed of the road mixer should be less than 3.3 km / h, the mixing depth should not be less than 0.22m in the paving thickness, and avoid plain soil interlayers, control the water content of the improved soil during mixing, so that the improved soil can reach the optimum water content sta...

Embodiment 2

[0034] The same as the construction method of the high-strength roadbed in Example 1, the difference is that the high-strength consolidation agent includes the following raw materials in parts by weight: 82 parts of Portland cement, 38 parts of composite ultrafine powder, 9 parts of quick-setting agent, polymer 16 parts of cellulose, 24 parts of modified polypropylene, 10 parts of alkali-free glass fiber; the composite ultrafine powder is composed of slag powder, fly ash and desulfurized gypsum with a mass ratio of 30:22:15:8:18:60 , metakaolin, coal gangue and polydimethylsiloxane, the material particle size D50 is below 8μm, the particle size D95 is below 20μm, and the specific surface area is 850-900m 2 / kg;

[0035] Among them, the polymer cellulose is hydroxypropyl methylcellulose and polyvinyl alcohol fiber with a mass ratio of 5:12; the Portland cement is a mixture of sulphoaluminate cement and ordinary Portland cement Compound cement, sulfoaluminate cement accounts fo...

Embodiment 3

[0037] The same as the construction method of the high-strength subgrade in Example 1, the difference is that the high-strength consolidation agent includes the following raw materials in parts by weight: 65 parts of Portland cement, 20 parts of composite ultrafine powder, 6 parts of quick-setting agent, polymer 13 parts of cellulose, 22 parts of modified polypropylene, and 8 parts of alkali-free glass fiber; the composite ultrafine powder is composed of slag powder, fly ash, and desulfurized gypsum with a mass ratio of 22:12:12:6:15:45 , metakaolin, coal gangue and polydimethylsiloxane, the material particle size D50 is below 8μm, the particle size D95 is below 20μm, and the specific surface area is 850-900m 2 / kg;

[0038] Among them, the polymer cellulose is hydroxypropyl methylcellulose and polyvinyl alcohol fiber with a mass ratio of 5:8; the Portland cement is a mixture of sulphoaluminate cement and ordinary Portland cement Compound cement, sulfoaluminate cement account...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com