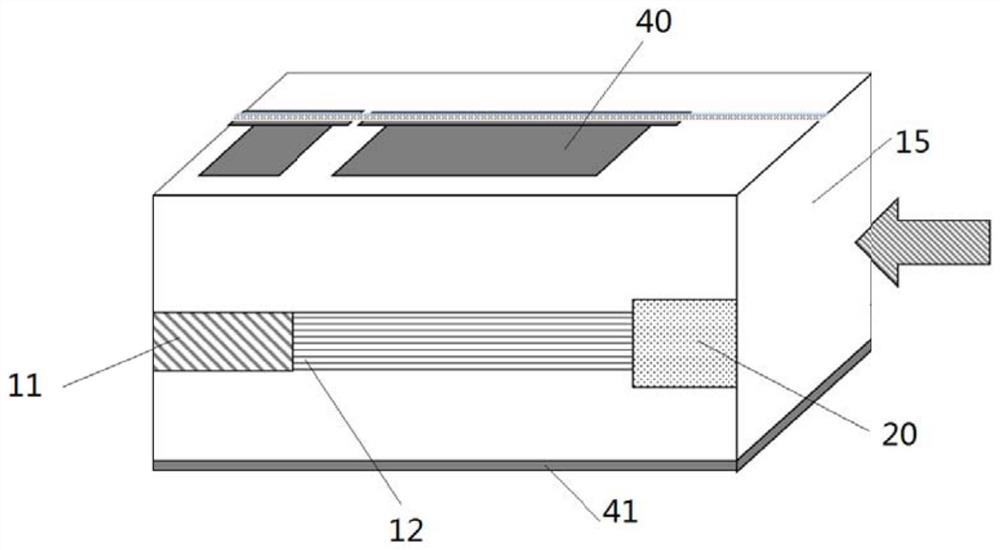

Communication optical amplifier and photodiode detector integrated component and preparation method

A photodiode and integrated component technology, applied in radiation control devices and other directions, can solve the problems of increasing the complexity of semiconductor epitaxy technology, loss, development cost and technical limitations, etc., to reduce the accuracy of epitaxy process requirements, easy to achieve, easy to achieve control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

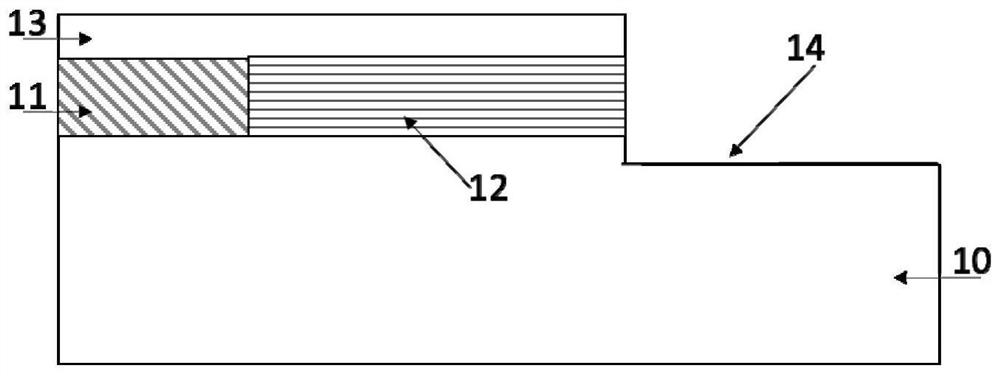

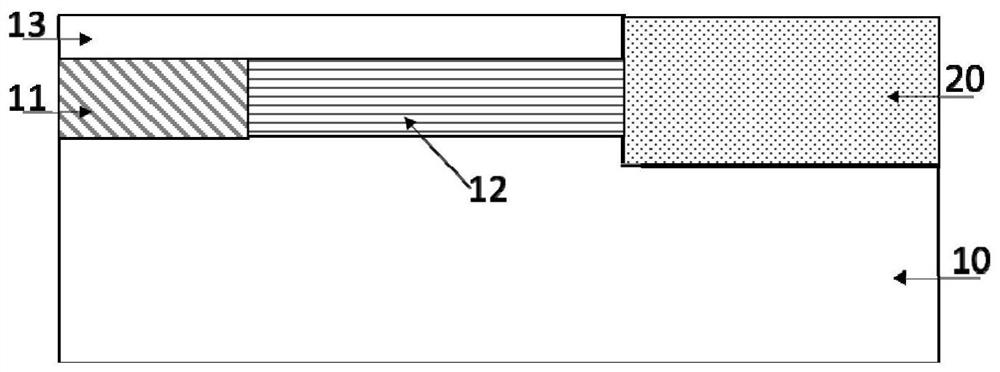

Embodiment 1

[0057] In this embodiment, the etching depth (that is, the height difference between the etched bottom surface of the end face etching region 14 and the bottom surface of the optical amplifier active layer 12) T1 and the thickness T2 of the pattern converter structure layer are optimally designed. Regarding the pattern converter region The optimization of the waveguide length Lssc and the waveguide width W2 at the light-receiving end of the mode-spot converter will be optimized and designed item by item in Embodiments 2 and 3, respectively. Therefore, in Example 1, the waveguide length Lssc in the mode spot converter area and the waveguide width W2 at the receiving end of the mode spot converter will first take the middle value of the value range (that is, Lssc=35um and W2=6.5um), and so on The value optimizes the etching depth T1; the optimization result is as follows Figure 4a As shown, when the thickness T2 of the pattern converter structure layer reaches 500nm, the improv...

Embodiment 2

[0059]In order to optimize the design of the waveguide length Lssc in the speckle converter area in this embodiment, the optimum etching depth T1=150nm in Example 1 and the optimized structural layer thickness of the speckle converter T2=500nm are taken as the design premise, and the speckle conversion The waveguide width W2 at the receiving end of the receiver is taken as the middle value of the value range (W2=6.5um); Figure 4b As shown, the coupling loss is measured when the waveguide length Lssc in the mode spot converter area is 20 um -50 um. In the mode spot converter area, the waveguide length Lssc=45um has the lowest coupling loss value of 4.9dB, so the length is The optimal waveguide length and the coupling loss can be improved by 0.6dB compared with Lssc=35um in the original embodiment 1.

Embodiment 3

[0061] This embodiment is to optimize the waveguide width W2 at the light-receiving end of the speckle converter. The optimal etching depth T1=150nm in Examples 1 and 2 is used, and the structural layer thickness of the speckle converter after optimization is T2=500nm and the optimum speckle The waveguide length Lssc=45um in the converter area is the design premise. Such as Figure 4c As shown, when the waveguide width W2=8um at the receiving end of the mode-spot converter, the coupling loss has approached the saturation value, and can reach an extremely low loss level less than 4dB. The improvement of W2 width is limited, considering the process production. High uniformity of the waveguide width is conducive to the premise of production control, so W2=8um is the optimal waveguide length, and the coupling loss can be improved by 0.95dB compared with the design of W2=6.5um in the original embodiment 2, and the final coupling loss value It can reach 3.95dB, and this coupling lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com