Fish feed preparation process and fish feed prepared by same

A preparation process and fish feed technology are applied in the field of fish feed preparation technology and the prepared fish feed, which can solve problems such as unfavorable fish digestion of feed, lower feed utilization rate, lower breeding efficiency, etc. The effect of improving feed utilization and improving breeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

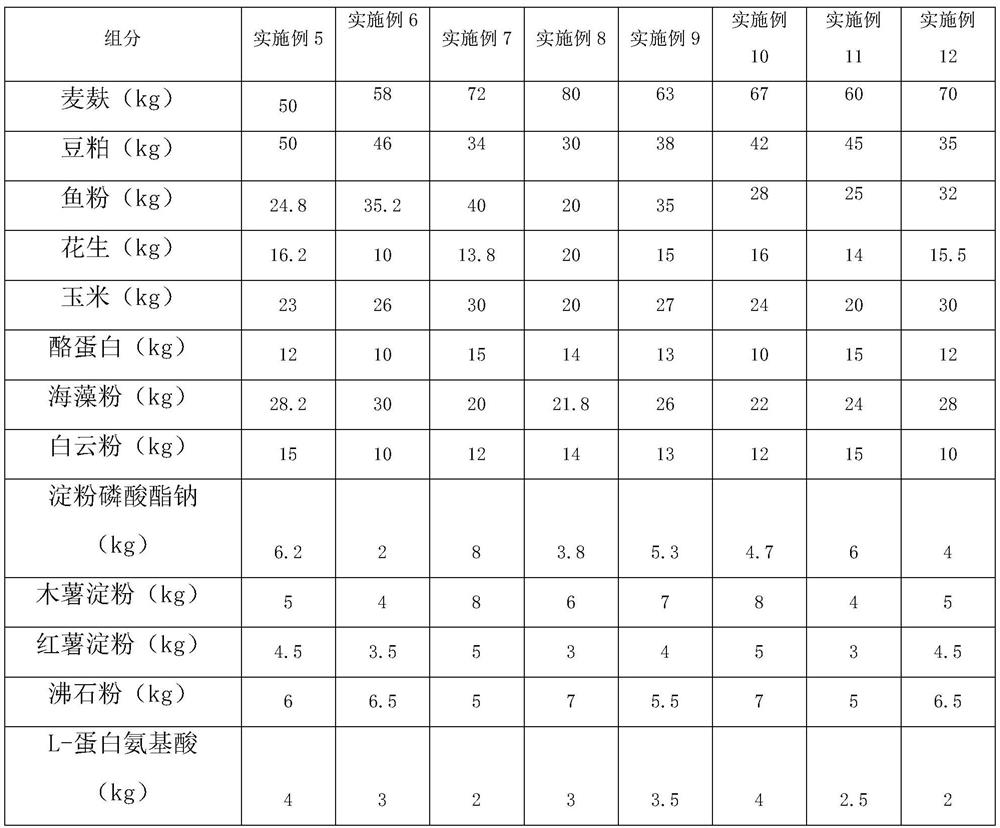

Examples

Embodiment 1

[0037] Embodiment 1: a kind of fish feed preparation technology, comprises the steps:

[0038] S1 Mixing: Weigh 45kg of water, add 4Kg of L-protein amino acid, mix evenly, stir at a speed of 150 rpm, heat to 55°C, continue stirring for 20min, the L-protein amino acid gradually dissolves, and then add 6kg of particle size The zeolite powder not larger than 40 μm is stirred continuously for 5 minutes to obtain wet zeolite powder; the wet zeolite powder is dried at 100° C. for 200 minutes to obtain modified zeolite powder. Weigh 65kg wheat bran, add 40kg soybean meal, 30kg fish meal, 15kg peanut, 25kg corn, 12kg casein, 25kg seaweed powder, 12kg dolomite powder, 5kg starch sodium phosphate, 6kg tapioca starch, 4kg sweet potato starch and modified zeolite powder, Mix evenly to prepare a mixture.

[0039] S2 Pulverization: pulverize the mixture with a pulverizer, sieve with a sieve with a pore size of 100 μm, and continue pulverizing the particles with a particle size larger than ...

Embodiment 2

[0044] The difference between embodiment 2 and embodiment 1 is that embodiment 2 does not add tapioca starch, and others are all consistent with embodiment 1.

Embodiment 3

[0046] The difference between embodiment 3 and embodiment 1 is that embodiment 3 does not add sweet potato starch, and others are all consistent with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com