Production method of mildew-proof and high-strength corrugated base paper

A technology for corrugated base paper and production method, which is applied in textiles and papermaking, addition of anti-biological reagents, and paper, etc., can solve the problems that corrugated base paper does not have flame retardancy, does not have antibacterial and anti-mildew effects, and corrugated base paper is easy to soften. , to achieve the effect of improving the anti-mildew effect, enhancing the interweaving force and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

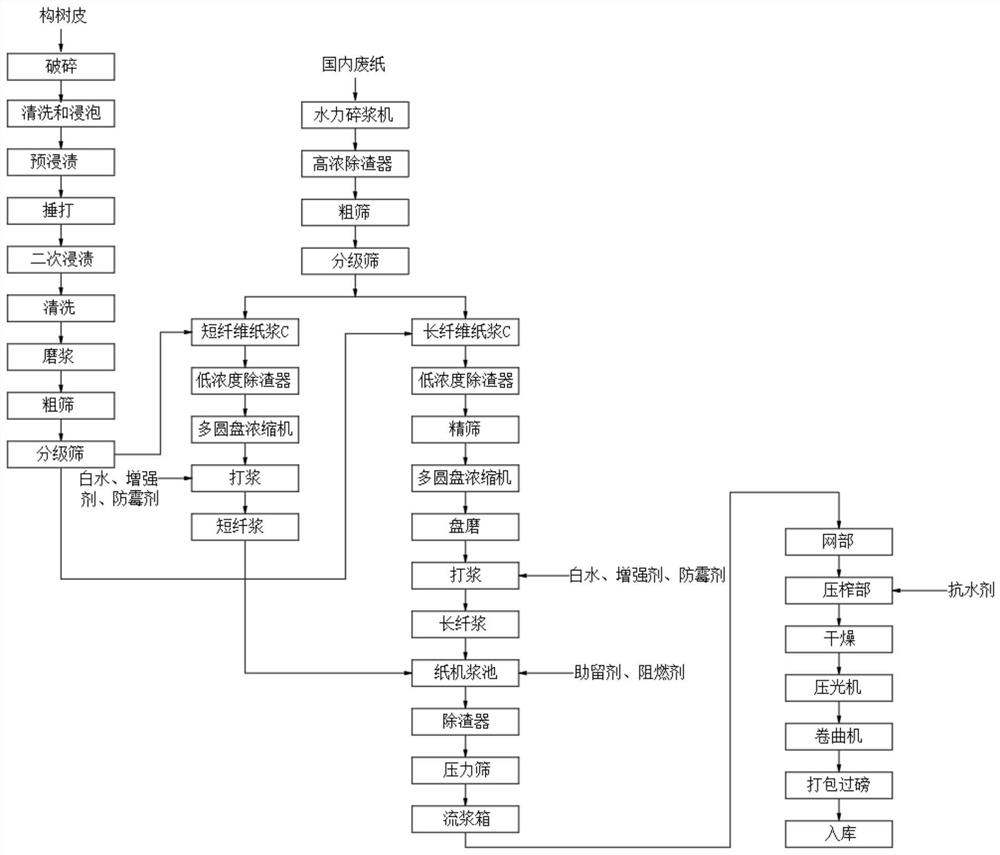

Method used

Image

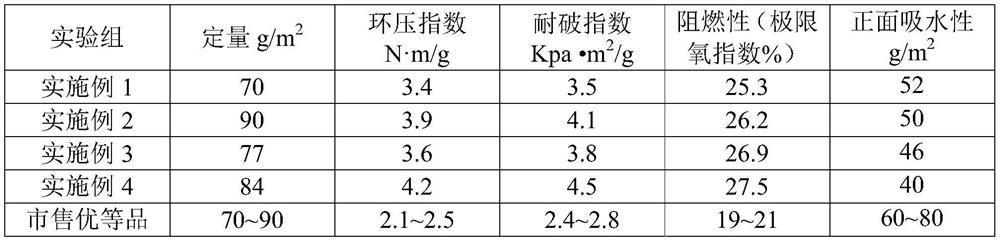

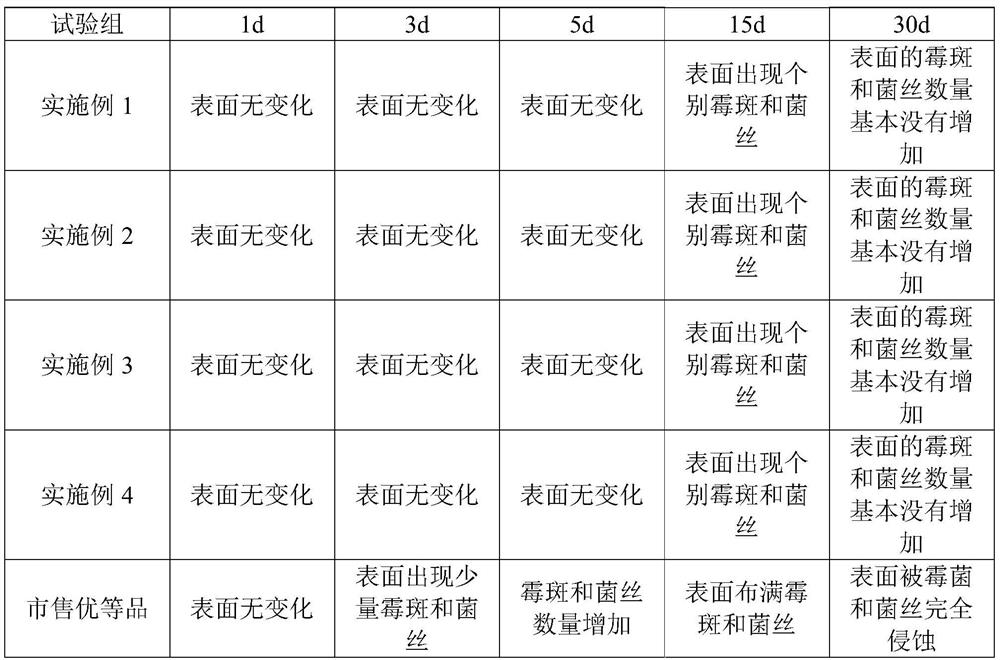

Examples

Embodiment 1

[0038] A method for producing mildew-proof and high-strength corrugated base paper of this embodiment comprises the following steps:

[0039] S1: Domestic Waste Paper Treatment

[0040] Put the domestic waste paper into the hydraulic pulper and fully disintegrate it, then send it to the high-concentration slag remover to remove the slag, and then pass through the coarse sieve and the grading sieve to screen out the short-fiber pulp A and long-fiber pulp A, and the sieve of the grading sieve The width is 0.06mm, and the pressure difference of the grading screen is 20kpa;

[0041] S2: Structural bark treatment

[0042] After the bark is crushed, cleaned and soaked, pre-impregnated, hammered, secondary impregnated, cleaned and refined, coarse sieves and grading sieves are carried out to screen short-fiber pulp B and long-fiber pulp B, Among them, the chemical solution used for pre-impregnation and secondary impregnation is composed of hydrogen peroxide and sodium hydroxide, the...

Embodiment 2

[0050] A method for producing mildew-proof and high-strength corrugated base paper, comprising the following steps:

[0051] In step S2, the temperature during pre-impregnation and secondary impregnation is both 30°C, and the time for pre-impregnation and secondary impregnation is both 8h;

[0052] In step S3, short-fiber pulp A and short-fiber pulp B are uniformly mixed in a ratio of 8:1 in parts by mass to obtain short-fiber pulp C, and long-fiber pulp A and long-fiber pulp B are mixed in a ratio of 8:1 in parts by mass. : The ratio of 1 is uniformly mixed to obtain long-fiber pulp C;

[0053] In step S3, the reinforcing agent is a binary reinforcing agent composed of polyacrylamide and dialdehyde starch, and the mass-to-number ratio of polyacrylamide, dialdehyde starch and short fiber pulp is 0.007:0.005:1, polyacrylamide, bisaldehyde The mass fraction ratio of aldehyde starch and long fiber pulp is 0.007:0.005:1, and antifungal agent is made up of fumaric acid and Kathon,...

Embodiment 3

[0058] A method for producing mildew-proof and high-strength corrugated base paper, comprising the following steps:

[0059] In step S2, the temperature during pre-impregnation and secondary impregnation is both 23 ° C, and the time of pre-impregnation and secondary impregnation is 4 hours;

[0060] In step S3, short-fiber pulp A and short-fiber pulp B are uniformly mixed in a ratio of 10:1 in parts by mass to obtain short-fiber pulp C, and long-fiber pulp A and long-fiber pulp B are mixed in a ratio of 10 in parts by mass. : The ratio of 1 is uniformly mixed to obtain long-fiber pulp C;

[0061] In step S3, the reinforcing agent is a binary reinforcing agent composed of polyacrylamide and dialdehyde starch, and the mass-number ratio of polyacrylamide, dialdehyde starch and short fiber pulp is 0.004:0.002:1, polyacrylamide, bisaldehyde The mass fraction ratio of aldehyde starch and long fiber pulp is 0.004:0.002:1, and antifungal agent is made up of fumaric acid and Kathon, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com