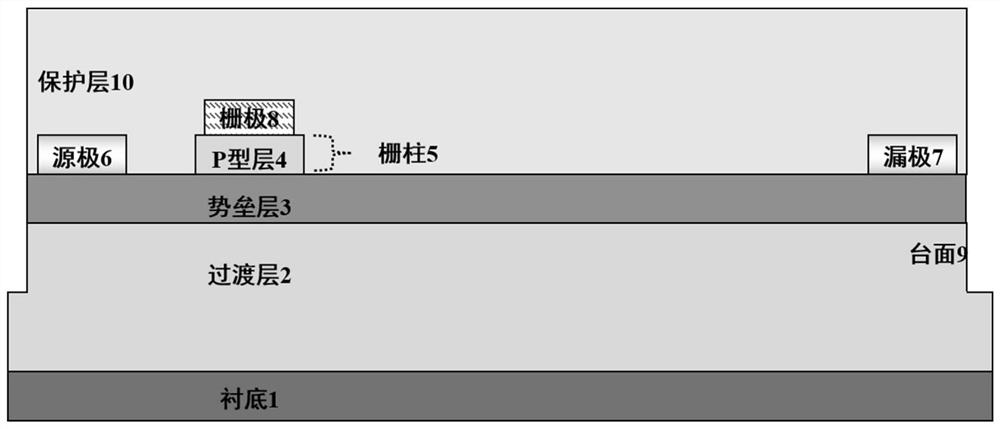

Enhanced high electron mobility transistor and manufacturing method thereof

A high electron mobility, transistor technology, applied in the field of microelectronics, can solve the problems of lower device yield, high manufacturing cost, cumbersome process debugging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

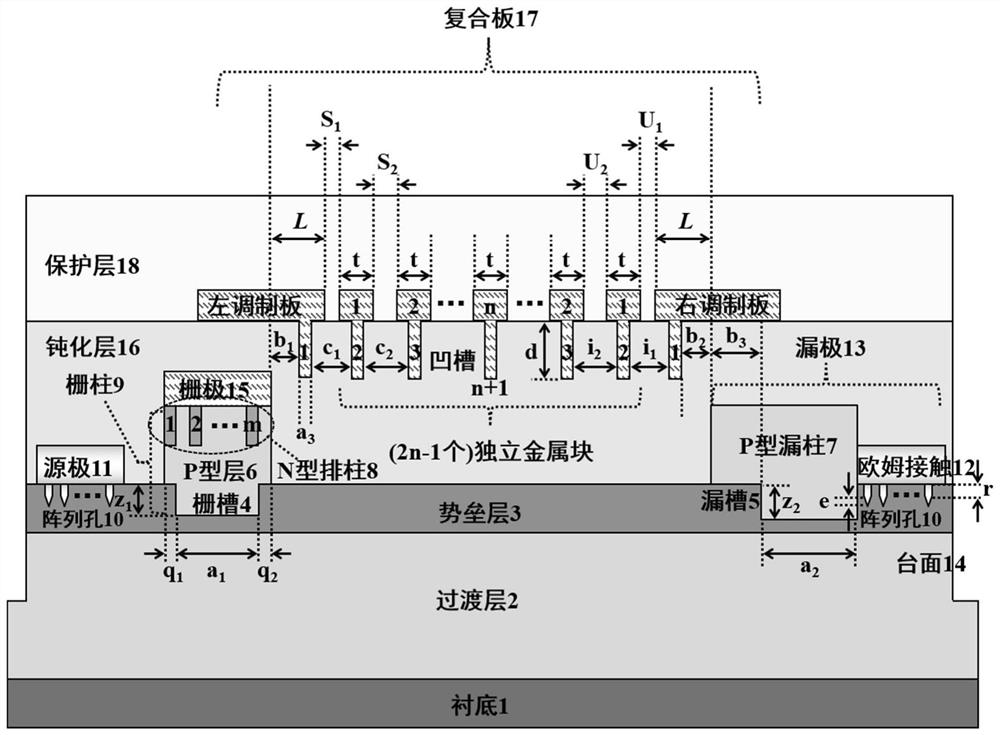

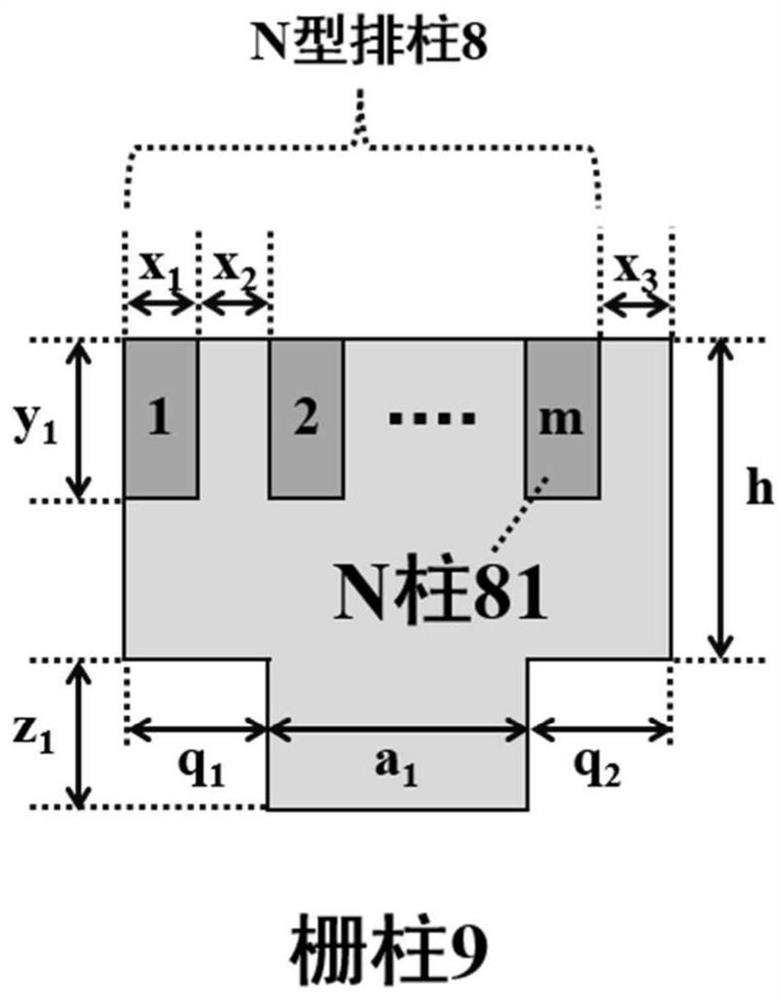

Embodiment 1

[0083] Embodiment 1: The thickness h of the P-type layer 6 is 20 nm, and the doping concentration of the P-type layer 6 is 5×10 20 cm -3 , N-type column 8 depth y 1 10nm, doping concentration is 5×10 20 cm -3 , the number of N columns 81 is 1, the length of grid columns 9 is 4nm, the array hole 10 is composed of 2×2 holes of the same size, the number of grooves is 3, and the number of independent metal blocks is 1. type high electron mobility transistors.

[0084] Step 1. Epitaxial GaN material is made transition layer 2 on sapphire substrate 1, as Figure 7 a.

[0085] 1a) GaN material with a thickness of 30nm was epitaxially grown on the sapphire substrate 1 by metal-organic chemical vapor deposition technology. The source flow rate is 22μmol / min;

[0086] 1b) GaN material with a thickness of 0.97 μm is epitaxially grown on the GaN material by metal-organic chemical vapor deposition technology to form an undoped transition layer 2. The process conditions are as follow...

Embodiment 2

[0130] Embodiment 2: The thickness h of making the P-type layer 6 is 200nm, and the doping concentration of the P-type layer 6 is 1×10 19 cm -3 , N-type column 8 depth y 1 80nm, the concentration is 5×10 19 cm -3 , the number of N columns 81 is 3, the length of grid columns 9 is 1800nm, the array hole 10 is composed of 5×5 holes of the same size, the number of grooves is 5, and the number of independent metal blocks is 3. type high electron mobility transistors.

[0131] Step 1. Epitaxially AlN and GaN materials on the silicon carbide substrate 1 to form the transition layer 2, such as Figure 7 a.

[0132] 1.1) Metal-organic chemical vapor deposition technology is used at a temperature of 1000° C., a pressure of 45 Torr, a hydrogen flow rate of 4600 sccm, an ammonia gas flow rate of 4600 sccm, and an aluminum source flow rate of 5 μmol / min, on a silicon carbide substrate 1 Undoped AlN material with an epitaxial thickness of 100nm;

[0133] 1.2) Using metal-organic chem...

Embodiment 3

[0163] Embodiment 3: The thickness h of the P-type layer 6 is 300 nm, and the doping concentration of the P-type layer 6 is 1×10 16 cm -3 , N-type column 8 depth y 1 250nm, doping concentration is 1×10 16 cm -3 , the number of N columns 81 is 5, the length of grid columns 9 is 5000nm, the array hole 10 is composed of 10×10 holes of the same size, the number of grooves is 7, and the number of independent metal blocks is 5. type high electron mobility transistors.

[0164] Step A. Epitaxial AlN and GaN materials on the silicon substrate 1 from bottom to top to make the transition layer 2, such as Figure 7 a.

[0165] First, AlN material with a thickness of 400nm is epitaxially grown on silicon substrate 1 by metal-organic chemical vapor deposition technology. The process condition that the source flow is 25μmol / min;

[0166] Then, use metal organic chemical vapor deposition technology to epitaxially GaN material with a thickness of 9.6 μm on the AlN material to complete ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

| Work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com