Special slow/controlled-release fertilizer for ratoon rice and preparation method thereof

A slow-controlled-release fertilizer and regenerated rice technology, applied in application, nitrogen fertilizer, potash fertilizer and other directions, can solve the problems of frequent fertilization, time-consuming and labor-intensive, and high fertilization cost, achieve long delay and control time, increase the number of tillers and yield, and light simplification. The effect of fertilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

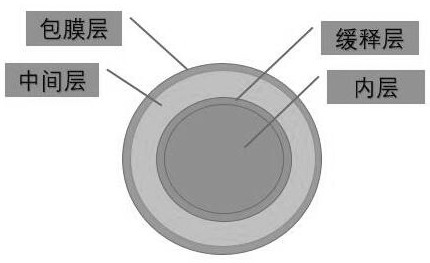

[0027] A special slow-release fertilizer for ratooning rice, which is composed of an inner layer, a slow-release layer, an intermediate layer and a coating layer; the inner layer is prepared from the following raw materials in parts by weight: 155 parts of urea powder, 280 parts of superphosphate 125 parts of potassium chloride, 1 part of liquid ammonia, 2 parts of granulation binder;

[0028] The slow-release layer is formed by mixing hydroxymethyl cellulose and bentonite according to the mass ratio of 1:2, and the mass fraction ratio of the slow-release layer to the inner layer is 1:15;

[0029] The middle layer is prepared from the following raw materials in parts by weight: 180 parts of urea powder, 450 parts of superphosphate, 130 parts of potassium chloride, 1 part of liquid ammonia, and 4 parts of granulation binder;

[0030] The coating layer is made of polyurethane and paraffin mixed according to the mass ratio of 4:1 and wrapped, and the mass fraction ratio of the co...

Embodiment 2

[0038] A kind of special slow-release fertilizer for ratooning rice, it is made up of inner layer, slow-release layer, middle layer and coating layer; Described inner layer is prepared from the following raw materials by weight: 166 parts of urea powder, 300 parts of superphosphate 140 parts of potassium chloride, 1.5 parts of liquid ammonia, 3 parts of granulation binder;

[0039] The slow-release layer is formed by mixing hydroxymethyl cellulose and bentonite according to the mass ratio of 1:2, and the mass fraction ratio of the slow-release layer to the inner layer is 1:18;

[0040] The middle layer is prepared from the following raw materials in parts by weight: 190 parts of urea powder, 475 parts of superphosphate, 143 parts of potassium chloride, 2 parts of liquid ammonia, and 5 parts of granulation binder;

[0041] The coating layer is made of polyurethane and paraffin mixed according to the mass ratio of 4:1 and wrapped, and the mass fraction ratio of the coating layer...

Embodiment 3

[0045] A kind of special slow and controlled release fertilizer for ratooning rice, which is composed of inner layer, slow release layer, middle layer and coating layer; the inner layer is prepared from the following raw materials in parts by weight: 180 parts of urea powder, 330 parts of superphosphate 165 parts of potassium chloride, 2 parts of liquid ammonia, 4 parts of granulation binder;

[0046] The slow-release layer is wrapped by mixing hydroxymethyl cellulose and bentonite according to the mass ratio of 1:2, and the mass fraction ratio of the slow-release layer to the inner layer is 1:20;

[0047] The middle layer is prepared from the following raw materials in parts by weight: 210 parts of urea powder, 500 parts of superphosphate, 155 parts of potassium chloride, 3 parts of liquid ammonia, and 6 parts of granulation binder;

[0048] The coating layer is made of polyurethane and paraffin mixed according to the mass ratio of 4:1 and wrapped, and the mass fraction ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com