Preparation method of cellulose composite aerogel

A composite aerogel and composite hydrogel technology, which is applied in the field of aerogel preparation, can solve the problems of low density, weak impact resistance, easy collapse, etc., and achieves a simple and controllable preparation method, good stability, and pollution. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

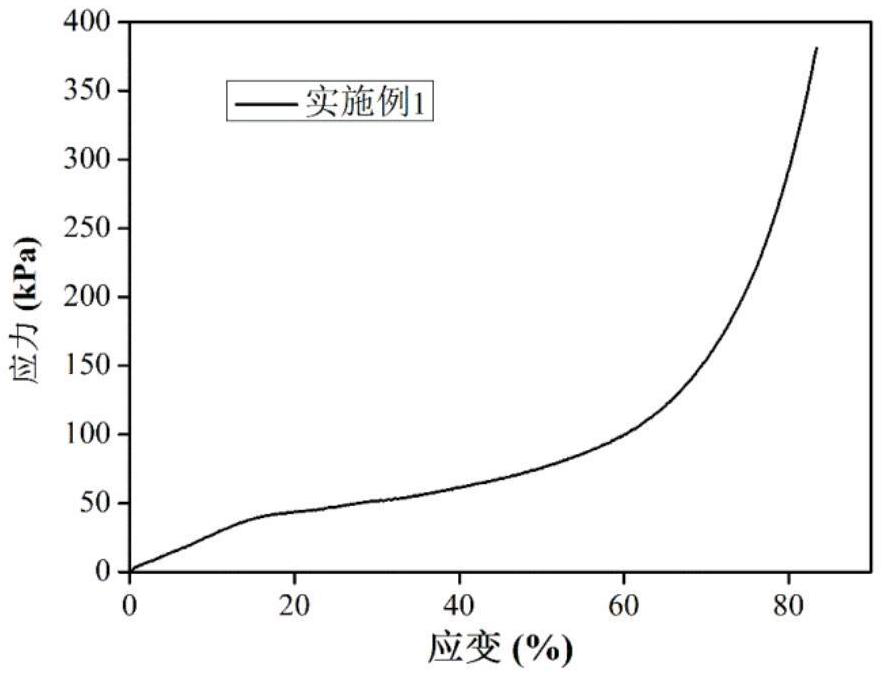

Embodiment 1

[0021] (1) Mix 7g sodium hydroxide, 12g urea, and 81g water evenly, and cool down to -12°C, and completely dissolve 4g microcrystalline cellulose in sodium hydroxide-urea-water solution on a magnetic stirrer to obtain 4wt% of A cellulose solution, wherein the microcrystalline cellulose particle size is 50 μm;

[0022] (2) Take 50g of cellulose solution in a beaker, add 0.6g of N,N-methylenebisacrylamide MBA, stir for 3h until N,N-methylenebisacrylamide MBA is completely dissolved, and then according to the mass ratio of 2 : 0.2, add 0.2g dopamine hydrochloride DA and continue to stir for 12h, divide the mixed solution into 10ml beakers with 5ml each, seal and place in a 90°C oven for 12h to obtain cellulose composite hydrogel;

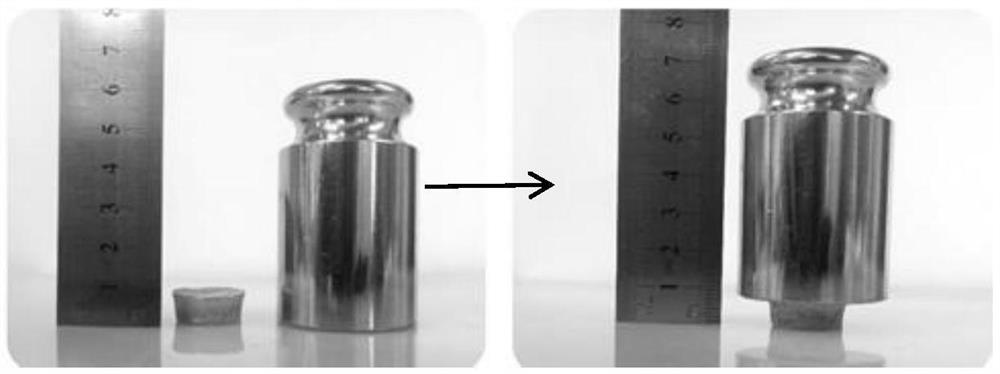

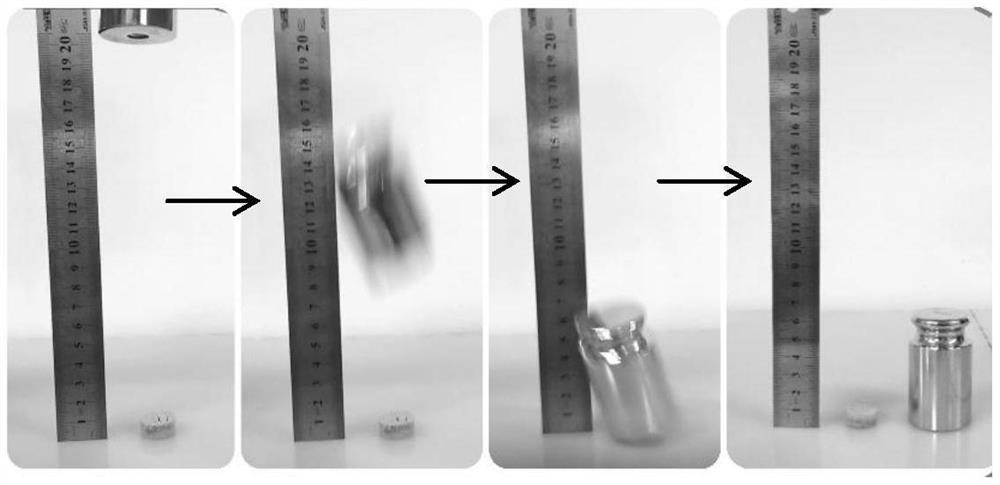

[0023] (3) Freeze the cellulose composite hydrogel at -15°C for 5 hours, and then dry it in a drier for 12 hours to obtain a preliminary cellulose composite aerogel. Wash to remove impurities, then perform solvent replacement with tert-butanol aqueous...

Embodiment 2

[0025] The difference between this embodiment and Example 1 is: when preparing cellulose composite hydrogel, use 40g cellulose solution, 0.4g N,N-methylenebisacrylamide MBA and 0.1g dopamine hydrochloride DA, oven temperature is 60°C.

Embodiment 3

[0027] (1) 7g sodium hydroxide, 12g urea, and 81g water were mixed uniformly, and cooled to -12°C, and 2g microcrystalline cellulose was completely dissolved in sodium hydroxide-urea-water solution on a magnetic stirrer to obtain 2wt% of Cellulose solution, the particle size of crystalline cellulose is 40 μm;

[0028] (2) Take 50g of cellulose solution in a beaker, add 0.3g of N,N-methylenebisacrylamide MBA, stir for 2h until the N,N-methylenebisacrylamide MBA is completely dissolved, then add 0.15g of hydrochloric acid Dopamine DA continued to stir for 12 hours, and the mixed solution was divided into 10ml beakers with 5ml each, sealed and placed in an oven at 100°C for 12h to obtain a cellulose composite hydrogel;

[0029] (3) Freeze the cellulose composite hydrogel at -15°C for 5 hours, and then dry it in a drier for 12 hours to obtain a preliminary cellulose composite aerogel. Wash to remove impurities, then perform solvent replacement with tert-butanol aqueous solution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com