LED indoor display screen optical protection material and preparation method thereof

A technology for optical protection and display screens, applied in anti-corrosion coatings, fire-resistant coatings, polyester coatings, etc., can solve the problems of affecting the light emission of lamp beads, black spots of glue dispensing, waste of damage rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

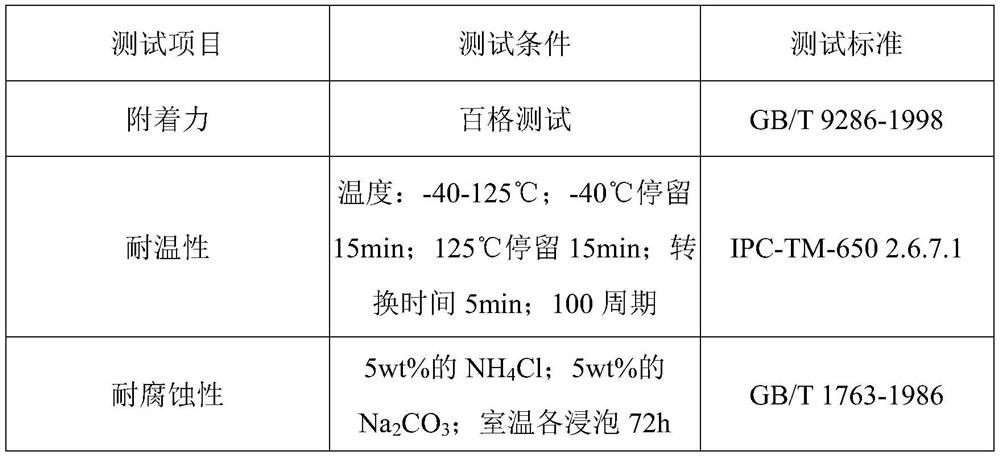

Method used

Image

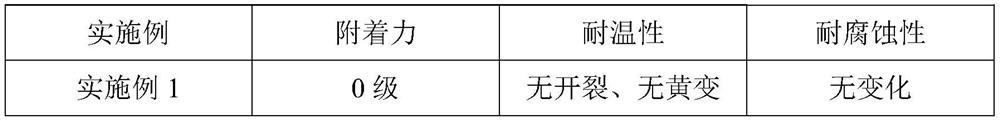

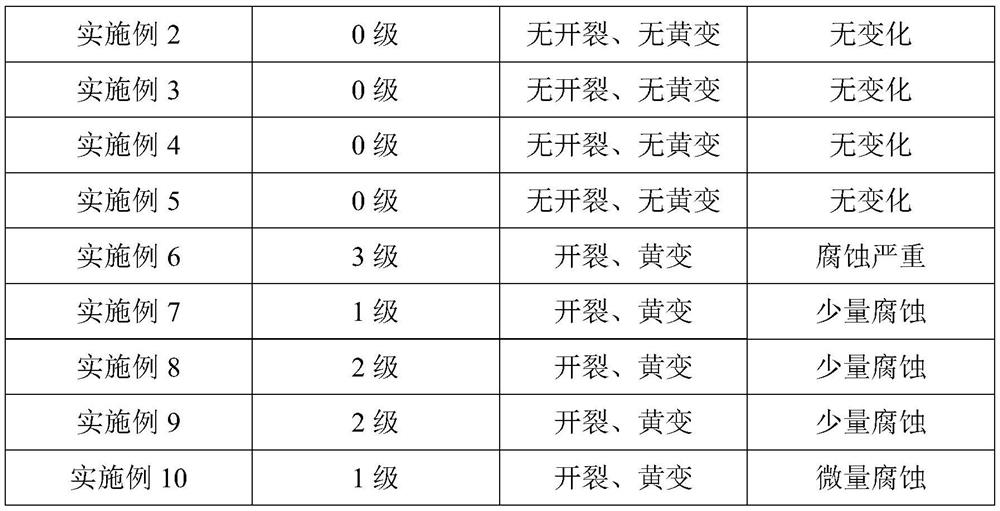

Examples

preparation example Construction

[0078] The second aspect of the present invention provides a method for preparing the optical protection material for the LED indoor display screen, which includes the following steps: mixing and stirring polyester resin, alkanes, solvents and other additives uniformly; then adding coupling agent and matting powder Mix with toner, continue to stir for 10-30 minutes, and filter to obtain.

[0079] In the course of research, the inventor found that the present invention uses reasonable compounding of the raw materials of each component, especially the use of silicone modified polyester resin, suitable solvents and toners, so that the prepared protective material has excellent weather resistance and resistance. Yellowing, high and low temperature resistance, good adhesion to the LED display, and easy to remove and repair. After coating on the LED display, it can avoid color difference problems. The inventor believes that the possible reason is that the present invention adopts the c...

Embodiment 1

[0084] Example 1 provides an optical protection material for LED indoor display screens. The raw materials for preparing the protection material, in parts by weight, include the following components: 40 parts of polyester resin, 30 parts of alkanes, 20 parts of solvents, and matting powder 4 Parts, 1 part toner, 1 part coupling agent, 5 parts other auxiliary agents.

[0085] The polyester resin is a silicone modified polyester resin, selected from Changxing Chemical, model ETERKYD50761-S-60; the alkane is octane; the solvent is a combination of ethyl acetate and n-butanol, and the volume ratio is 3 :1; The matting powder is an organic matting powder, selected from Guangzhou Xianrenhui International Trade Co., Ltd., model M2; the toner is a black metal complex powder, selected from Shanghai Yinsai Industrial Co., Ltd., model BLACK- 29; The silane coupling agent is KH550; the other additives are wetting agents, leveling agents, defoamers and rheology additives, the weight ratio is ...

Embodiment 2

[0088] Example 2 provides an optical protection material for LED indoor display screens. The raw materials for preparing the protection material, in parts by weight, include the following components: 50 parts of polyester resin, 30 parts of alkane, 10 parts of solvent, and matting powder 4 Parts, 1 part of toner, 2 parts of coupling agent, 5 parts of other auxiliary agents.

[0089] The polyester resin is a silicone modified polyester resin, selected from Changxing Chemical, model ETERKYD50761-S-60; the alkane is octane; the solvent is a combination of ethyl acetate and n-butanol, and the volume ratio is 3 :1; The matting powder is organic matting powder, selected from Guangzhou Xianrenhui International Trade Co., Ltd., model M2; the toner is black metal complex powder, selected from Shanghai Yinsai Industrial Co., Ltd., model BLACK- 29; The silane coupling agent is KH550; the other additives are wetting agents, leveling agents, defoamers and rheology additives, and the weight ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com