A Browning Method for Improving Interlayer Cohesion of Printed Circuit Board

A printing circuit and bonding force technology, which is applied in the field of browning to improve the bonding force between layers of printed circuit boards, can solve problems such as air bubbles and low bonding force between layers, and achieve excellent comprehensive performance, strong bonding force between layers, good resistance The effect of peel performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

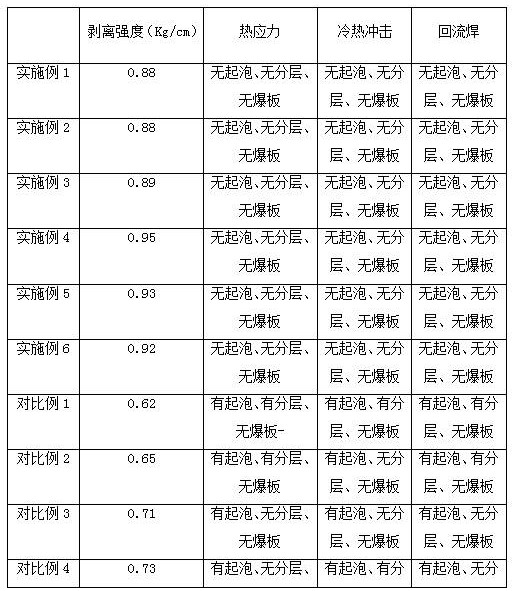

Examples

Embodiment 1

[0033] This embodiment provides a browning method for improving the bonding force between layers of printed circuit boards, comprising the following steps:

[0034] S1: Cleaning: Soak the copper foil in cleaning solution Ⅰ at room temperature for 3 minutes, then add cleaning solution Ⅱ, the mass ratio of cleaning solution Ⅰ to cleaning solution Ⅱ is 1:2, continue to soak at room temperature for 3 minutes, and then place in hydrogen peroxide and Soak in ethanol at room temperature for 2 minutes, then blow dry with nitrogen;

[0035] S2: Pre-soaking: Put the cleaned copper foil in the pre-soaking solution, ultrasonically vibrate for 3 minutes, and the frequency is 40KHZ;

[0036] S3: browning: browning the pre-impregnated copper foil in a browning tank containing browning solution;

[0037] S4: Washing with water: place the browned copper foil in deionized water, wash with water, and blow dry with nitrogen.

[0038] The cleaning solution I is made of the following components i...

Embodiment 2

[0042] This embodiment provides a browning method for improving the bonding force between layers of printed circuit boards, comprising the following steps:

[0043] S1: Cleaning: Soak copper foil in cleaning solution Ⅰ at room temperature for 4 minutes, then add cleaning solution Ⅱ, the mass ratio of cleaning solution Ⅰ to cleaning solution Ⅱ is 1:2, continue to soak at room temperature for 4 minutes, and then place in hydrogen peroxide and Soak in ethanol at room temperature for 3 minutes, then blow dry with nitrogen;

[0044] S2: Pre-soaking: Put the cleaned copper foil in the pre-soaking solution, ultrasonically vibrate for 4 minutes, and the frequency is 40KHZ;

[0045] S3: browning: browning the pre-impregnated copper foil in a browning tank containing browning solution;

[0046] S4: Washing with water: place the browned copper foil in deionized water, wash with water, and blow dry with nitrogen.

[0047] The cleaning solution I is made of the following components in pa...

Embodiment 3

[0051] This embodiment provides a browning method for improving the bonding force between layers of printed circuit boards, comprising the following steps:

[0052] S1: Cleaning: Soak the copper foil in cleaning solution Ⅰ at room temperature for 5 minutes, then add cleaning solution Ⅱ, the mass ratio of cleaning solution Ⅰ to cleaning solution Ⅱ is 1:2, continue to soak at room temperature for 5 minutes, and then place it in hydrogen peroxide and Soak in ethanol at room temperature for 3 minutes, then blow dry with nitrogen;

[0053] S2: Pre-soaking: Put the cleaned copper foil in the pre-soaking solution, ultrasonically vibrate for 3 minutes, and the frequency is 40KHZ;

[0054] S3: browning: browning the pre-impregnated copper foil in a browning tank containing browning solution;

[0055] S4: Washing with water: place the browned copper foil in deionized water, wash with water, and blow dry with nitrogen.

[0056] The cleaning solution I is made of the following component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com