Preparation of algae biological membrane and application of algae biological membrane in urban secondary effluent treatment

A technology of algae biofilm and secondary effluent, applied in the field of water treatment, can solve the problems of difficult harvesting of algae biomass, long hydraulic retention time, low treatment load, etc., and achieve good application prospects, easy cultivation and harvesting, and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

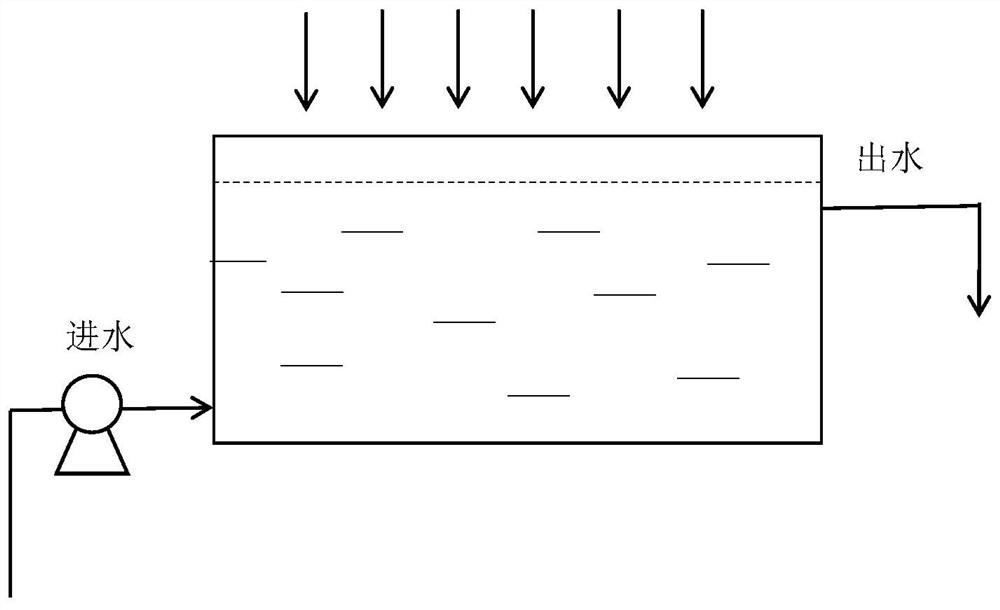

[0021] A kind of preparation method of algae biofilm of the present invention, comprises the steps:

[0022] (1) Expanded cultivation of microalgae: adding microalgae into a microalgae membrane reactor filled with microalgae culture solution for expanded cultivation to increase the density of algae cells. Expanded culture conditions: under the conditions of light intensity of 3000Lux-4000Lux, light-dark ratio of 12h:12h, and temperature of 23±2°C, aerated culture for 5d-8d, so that the microalgae grow well and quickly reach the logarithmic growth phase; preferred The microalgae were inoculated into the culture solution at an inoculation amount of 5% by volume of the microalgae culture solution.

[0023] Preferably, the microalgae is any one of Spirulina, Scenedesmus, Synechococcus or Chlorella.

[0024] Preferably, when the microalgae is Scenedesmus, Synechococcus or Chlorella, the microalgae culture medium (medium) is BG-11, which is available in the market; when the microal...

Embodiment 1

[0033] (1) Expanded cultivation of microalgae: Prepare 20 L of culture solution and add it to the microalgae membrane reactor. The culture medium of this embodiment is BG-11 medium, NaNO 3 30g, K 2 HPO 4 0.8g, MgSO 4 .7H 2 O 1.5g, CaCl 2 ·7H 2 O 0.72g, Na 2 CO 3 0.4g, citric acid 0.12g, ferric citrate 0.12g, trace element A5 20mL. Transfer 1000mL of Chlorella algae to BG-11 culture medium, under the conditions of light intensity of 3500Lux, light-dark ratio of 12h:12h, and temperature of 23°C, aerated culture for 6 days, so that the growth of Chlorella reaches the logarithmic phase .

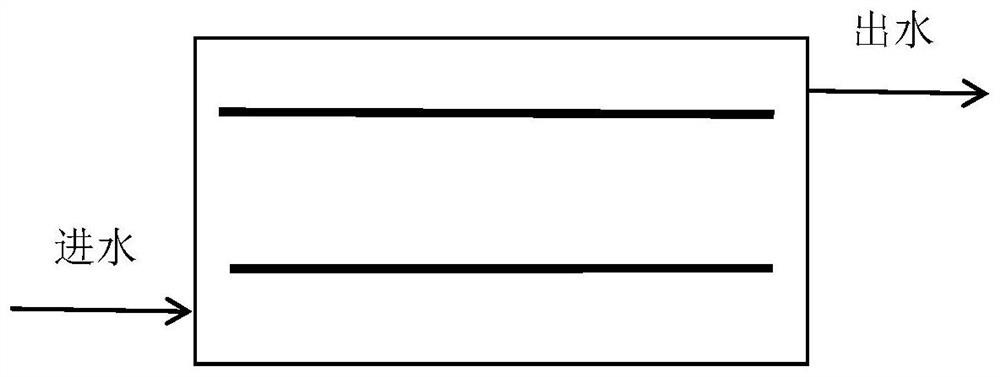

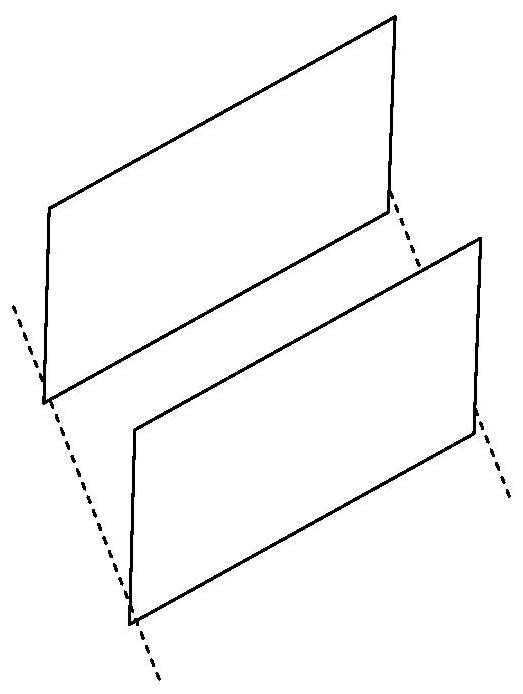

[0034](2) Preparation of algae film: fix the biological curtain of polyester fiber in the reactor, immerse in the chlorella culture solution, under the conditions of light intensity 3500Lux, light-dark ratio 12h:12h, temperature 23 ℃, static After culturing for 6 days, the surface of the biofilm carrier is covered with algae, and the film hanging is completed, and the chlorella algae...

Embodiment 2

[0038] (1) Expanded cultivation of microalgae: Prepare 20 L of culture solution and add it to the microalgae membrane reactor. The culture fluid of this embodiment is Zarrouk medium NaHCO 3 336g, NaNO 3 50g, K 2 HPO 4 10g, MgSO 4 ·7H 2 O 4.0g, NaCl 20g, K 2 SO 4 20g, FeSO 4 ·7H 2 O 0.2g, Na 2 EDTA 0.8g, trace element A5 20mL. Transfer 1000mL of Spirulina algae into Zarrouk culture medium, under the conditions of light intensity of 4000Lux, light-dark ratio of 12h:12h, and temperature of 25°C, aerated culture for 5 days, so that the growth of Spirulina reached the logarithmic phase.

[0039] (2) Preparation of algae film: Fix the semi-soft carrier made of polyethylene material in the reactor, immerse in the spirulina culture solution, under the conditions of light intensity 4000Lux, light-dark ratio 12h:12h, temperature 25°C , under static culture for 4 days, until the surface of the biofilm carrier is covered with algae, and the film hanging is completed, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com