High-potential hydrophobic polypeptide monolayer film as well as preparation method and application thereof

A single-layer membrane, hydrophobic technology, applied in the field of natural polymers, can solve problems such as limiting the application of polypeptide molecules, and achieve the effect of improving cell adhesion and proliferation, and improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

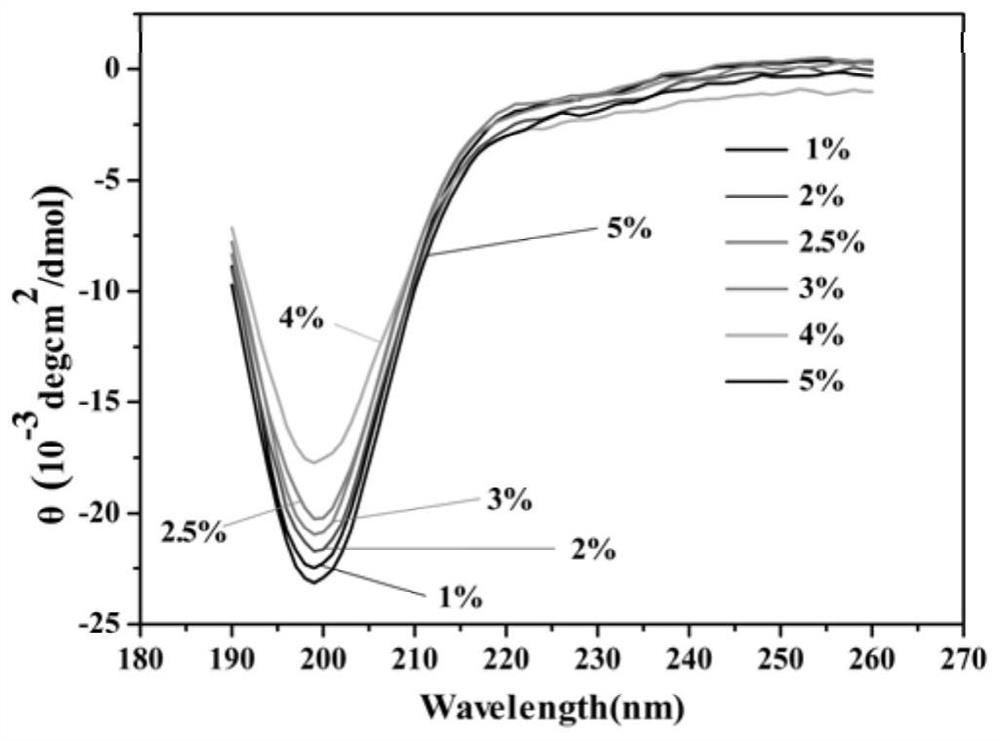

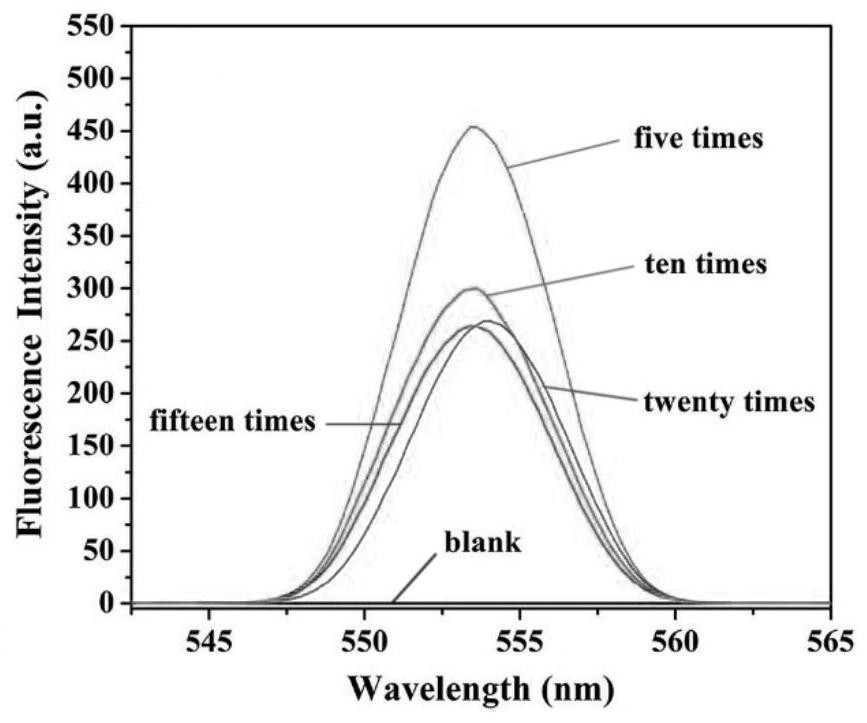

[0051] Embodiment 1 A method for preparing a polypeptide monolayer film, comprising the following steps:

[0052] (1) Prepare 50 mL of collagen peptide solution with a concentration of 4% wt: accurately weigh 100 mL of collagen peptide in a three-necked flask, accurately measure deionized water, pour the deionized water into the three-necked flask, and swell at room temperature for 0.5 h. Put the three-neck flask in a water bath at 50±1°C, heat and stir for 2 hours to dissolve it completely, then adjust the pH of the solution to 10.00±0.02 with 2mol / L sodium hydroxide, and stabilize it in the water bath for 0.5 hours.

[0053] (2) add surfactant SDS to above-mentioned collagen polypeptide solution, obtain collagen polypeptide-SDS mixed solution, the concentration of SDS in mixed solution is 7.50mmol / L (CMC, when 50 ℃, the critical micelle concentration of SDS); Stable in a water bath for 6h and set aside.

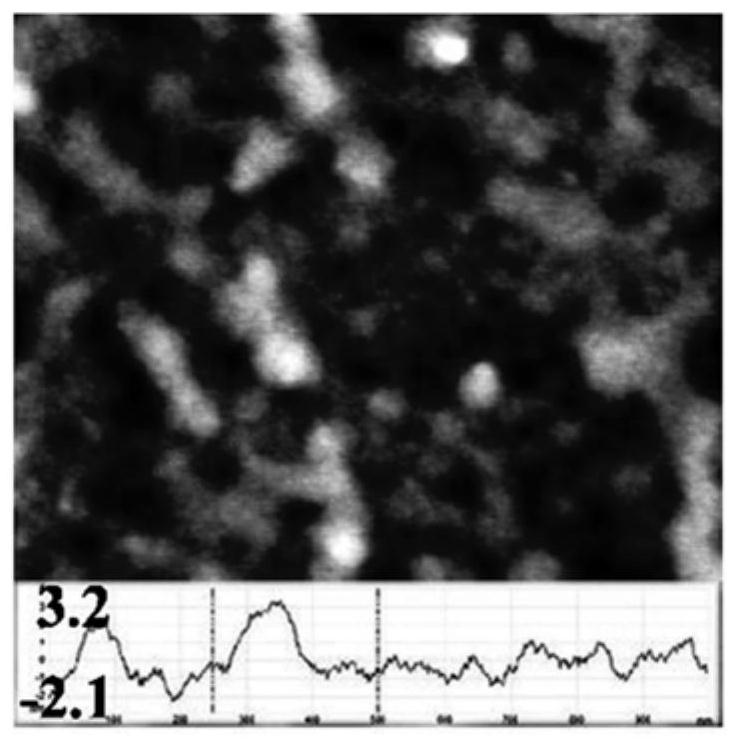

[0054] (3) Cut a rectangular titanium sheet with a size of 1cm×1cm×1m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com