Ultralow-temperature noise source assembly

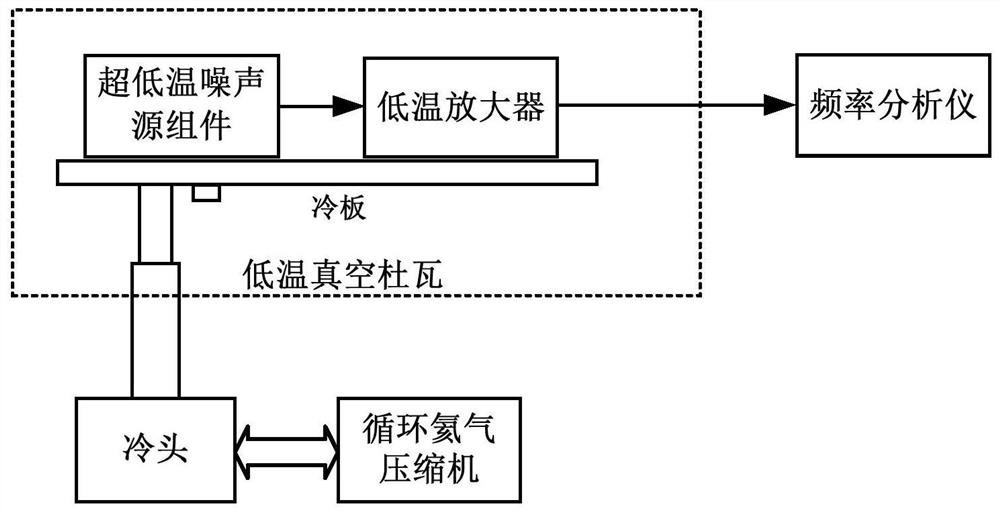

A noise source and ultra-low temperature technology, which is applied in the direction of improving the amplifier to reduce the impact of noise, can solve the problems of uneven temperature and error between RF cables and adapters, and achieve the effect of low working temperature, fast switching speed and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

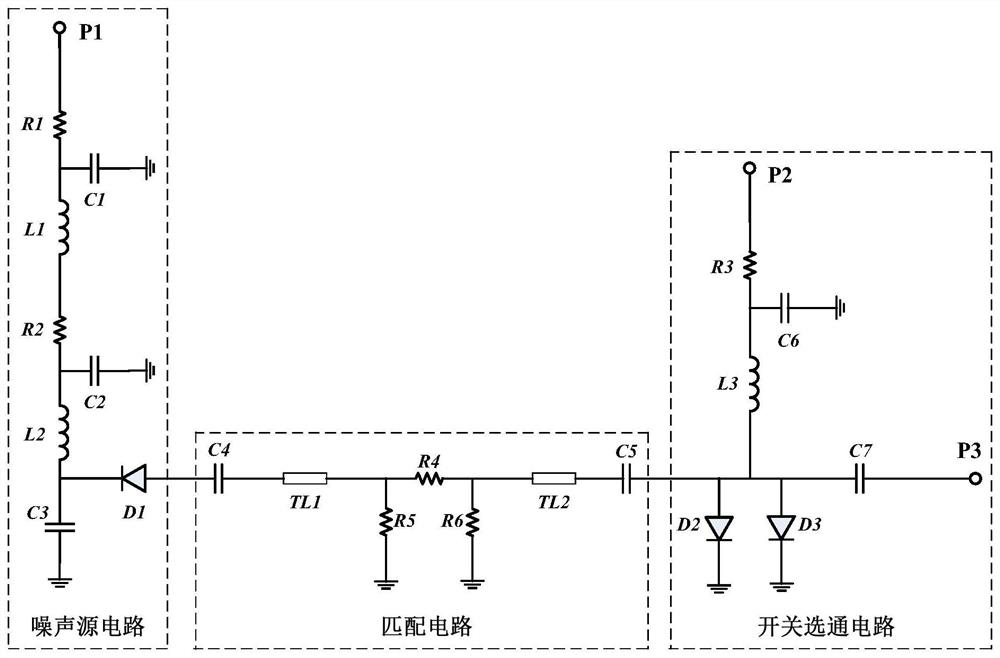

[0016] This embodiment provides an ultra-low temperature noise source assembly, such as figure 1 As shown, it includes a noise source circuit for generating noise signals, a matching circuit for impedance matching and amplitude adjustment, and a switch gating circuit for determining the signal output state. Wherein, the noise source circuit, the matching circuit and the gate switch circuit are serially connected in sequence.

[0017] Specifically, the noise source circuit includes a DC power supply port P1, capacitors C1-C4, inductors L1, L2, resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com