High-thermal-conductivity silicon-containing flame-retardant resin composition and application thereof

A technology of flame retardant resin and composition, applied in application, other household appliances, household appliances, etc., can solve the problems of not taking into account thermal conductivity, thermal expansion, heat-resistant dielectric constant, dielectric loss and flame retardancy at the same time, and achieve low Effects of water absorption, low dielectric constant, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

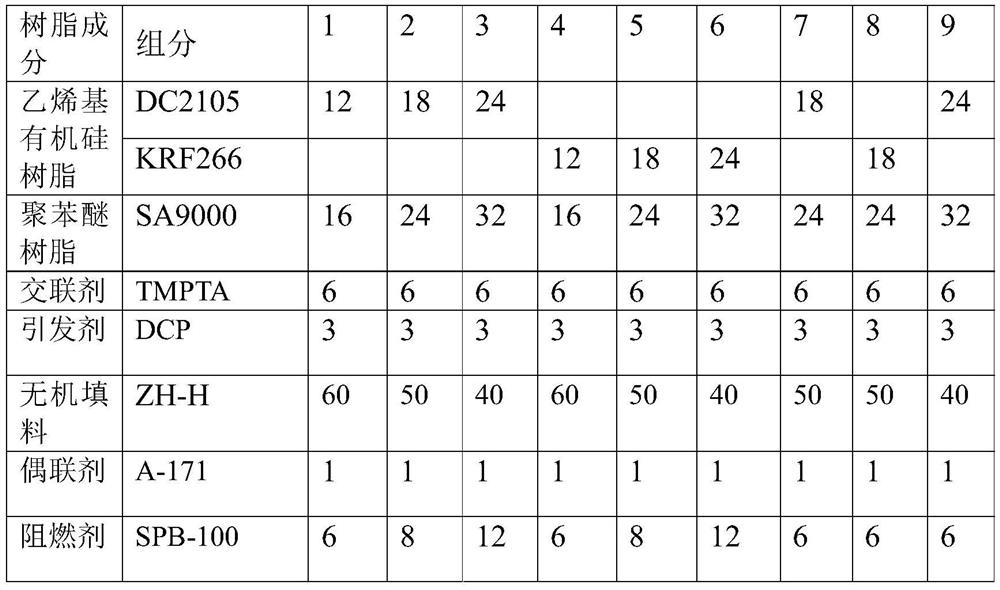

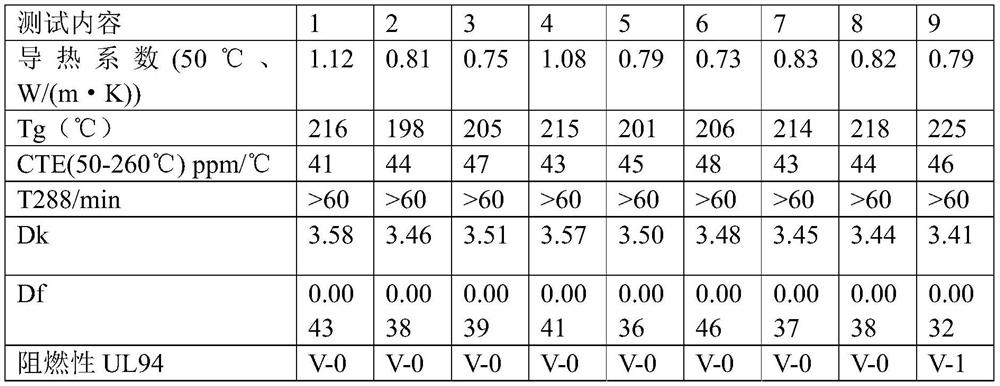

[0049] Preparation of High Thermal Conductivity Silicon-Containing Flame Retardant Resin Composition

[0050]According to the formulations listed in Table 1 and Table 2, the resin components and inorganic fillers were firstly mixed and dispersed in toluene to obtain resin compositions. Examples 1-9 respectively correspond to components 1-9 in Table 1. Then impregnate 1078 glass fiber cloth (Honghe Electronics) with the composition, heat and dry at 115° C. for 6 minutes to obtain a prepreg with a resin content of 65%-68%.

[0051] Five prepregs were stacked together, two copper foils with a thickness of 35 microns were placed on the upper and lower surfaces, and hot-pressed at 220 ° C and 4 MPa for 120 minutes to obtain a double-sided copper-clad laminate.

[0052] The copper foil is removed by etching to evaluate the dielectric constant, dielectric loss, thermal conductivity, glass transition temperature, thermal expansion coefficient, flame retardancy, etc.

[0053] The name...

Embodiment 10

[0075] A high thermal conductivity silicon-containing flame retardant resin composition, comprising the following components by mass:

[0076] Modified polyphenylene ether resin containing unsaturated carbon-carbon double bonds: 16 parts;

[0077] Vinyl silicone resin: 12 parts;

[0078] Peroxide initiator: 1 part;

[0079] Phosphorus-containing flame retardant: 5 parts;

[0080] Auxiliary cross-linking agent: 5 parts;

[0081] Inorganic filler: 35 parts.

[0082] In this embodiment, the modified polyphenylene ether resin containing unsaturated carbon-carbon double bonds is selected from: allyl grafted polyphenylene ether resin;

[0083] In this embodiment, the vinyl silicone resin is a methylphenyl silicone resin, its R / Si is between 1.0-1.5, and its Ph / Me value is between 0.6-0.9.

[0084] In this embodiment, the peroxide initiator is selected from the following substances: dibenzoyl peroxide (BPO).

[0085] In this embodiment, the phosphorus-containing flame retardant...

Embodiment 11

[0096] A high thermal conductivity silicon-containing flame retardant resin composition, comprising the following components by mass:

[0097] Modified polyphenylene ether resin containing unsaturated carbon-carbon double bonds: 40 parts;

[0098] Vinyl silicone resin: 25 parts;

[0099] Peroxide initiator: 6 parts;

[0100] Phosphorus-containing flame retardant: 15 parts;

[0101] Auxiliary cross-linking agent: 10 parts;

[0102] Inorganic filler: 60 parts.

[0103] In this embodiment, the modified polyphenylene ether resin containing unsaturated carbon-carbon double bonds is selected from: vinyl benzyl ether polyphenylene ether resin (resin of Mitsubishi Gas Chemical Co., Ltd. whose model is OPE-2s);

[0104] In this embodiment, the vinyl silicone resin is a methylphenyl silicone resin, its R / Si is between 1.0-1.5, and its Ph / Me value is between 0.6-0.9.

[0105] In this embodiment, the peroxide initiator is selected from the following substances: dicumyl di-tert-butyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com