Graphene modified waste tire thermal cracking carbon black composite material and preparation method thereof

A technology of pyrolysis carbon black and composite materials, which is applied in the field of preparation of graphene graft modified waste tire pyrolysis carbon black nano-composites, can solve the problem that the rubber field has not been widely industrialized and cannot reuse tires, It is difficult to solve problems such as market share, and achieve the effects of energy saving, performance optimization and low cost in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

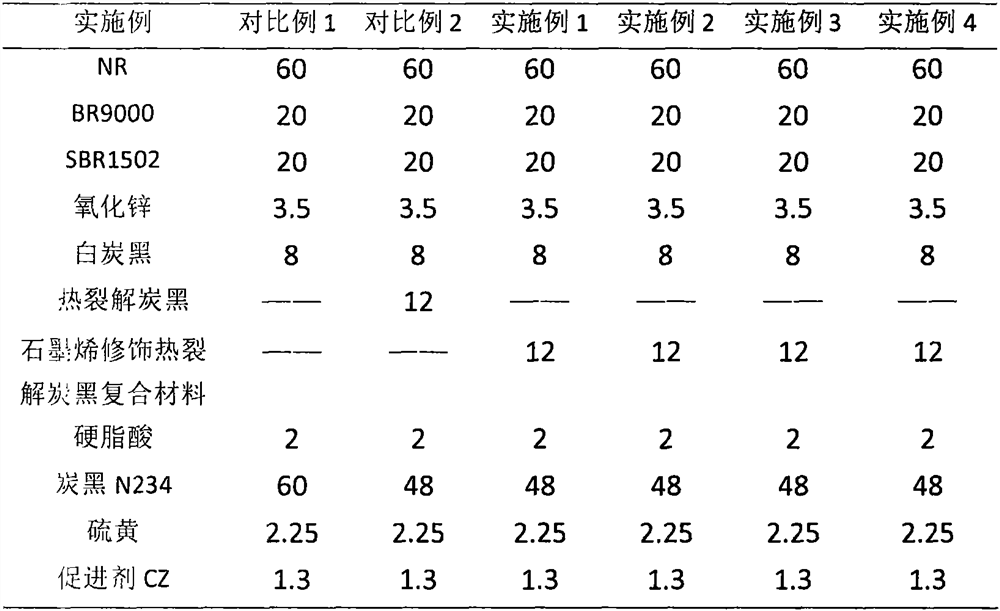

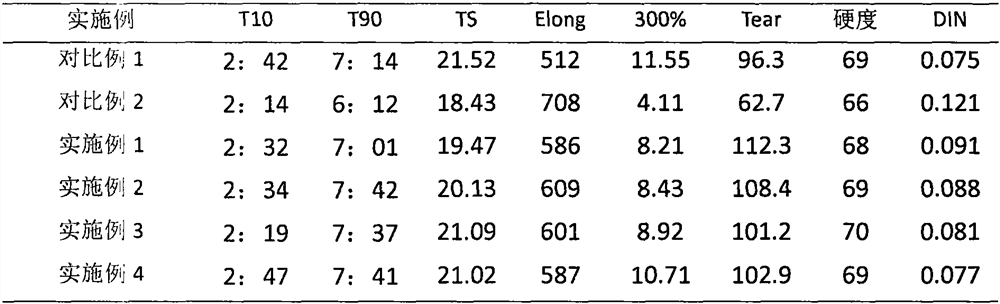

Examples

Embodiment 1

[0029] A method for preparing graphene-modified waste tire pyrolysis carbon black composite material, the specific preparation process is as follows:

[0030] (1) Preparation of aqueous dispersion of graphene oxide: add 1 g of NaCl-treated expanded graphite and 25 mL of concentrated sulfuric acid into a 250 mL flask and stir at room temperature for 4 hours, then heat the container to 40 ° C and add 100 mg NANO3 and 500 mg permanganate Potassium, continuously add water to keep the constant temperature reaction for 2 hours, then add water and 10mL of 30% hydrogen peroxide solution to terminate the reaction, and obtain a graphene oxide aqueous dispersion.

[0031] (2) Preparation and acidification treatment of thermal cracking carbon black aqueous dispersion: add 200g waste tire thermal cracking carbon black to the aqueous solution containing 1% sodium dodecylbenzenesulfonate, stir at constant temperature and high speed for 30 minutes at 40°C , that is, a stable thermal cracking ...

Embodiment 2

[0037] A method for preparing graphene-modified waste tire pyrolysis carbon black composite material, the specific preparation process is as follows:

[0038] (1) Preparation of aqueous dispersion of graphene oxide: Add 1 g of expanded graphite treated with NACl and 25 mL of concentrated sulfuric acid into a 250 mL flask and stir at room temperature for 4 hours, then heat the container to 40 ° C and add 100 mg NANO3 and 500 mg permanganese Potassium Oxide, continuously add water to keep the constant temperature reaction for 2 hours, then add water and 10mL of 30% hydrogen peroxide solution to terminate the reaction, and obtain the graphene oxide aqueous dispersion.

[0039] (2) Preparation and acidification treatment of thermal cracking carbon black aqueous dispersion: add 100 g of waste tire thermal cracking carbon black to an aqueous solution containing 1% sodium dodecylbenzene sulfonate, stir at constant temperature and high speed for 30 minutes at 40°C , that is, a stable ...

Embodiment 3

[0045] A method for preparing graphene-modified waste tire pyrolysis carbon black composite material, the specific preparation process is as follows:

[0046] (1) Preparation of aqueous dispersion of graphene oxide: add 1 g of expanded graphite treated with NACl and 25 mL of concentrated sulfuric acid into a 250 mL flask and stir at room temperature for 4 hours, then heat the container to 40 °C and add 100 mg NANO3 and 500 mg permanganate Potassium, continuously add water to keep the constant temperature reaction for 2 hours, then add water and 10mL of 30% hydrogen peroxide solution to terminate the reaction, and obtain a graphene oxide aqueous dispersion.

[0047] (2) Preparation and acidification treatment of thermal cracking carbon black aqueous dispersion: add 50 g of waste tire thermal cracking carbon black to an aqueous solution containing 1% sodium dodecylbenzenesulfonate, stir at constant temperature and high speed for 30 minutes at 40°C , that is, a stable thermal cra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com