Organic solid waste dry-type biogas fermentation system using continuous feeding and discharging equipment

A technology for biogas fermentation and organic solids, which is applied to specific-purpose bioreactors/fermenters, solid-phase fermentation bioreactors, and combinations of bioreactors/fermenters. No secondary pollution and other problems, to achieve the effect of improving the efficiency of feeding and discharging materials, facilitating the operation of feeding and discharging materials, and low construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

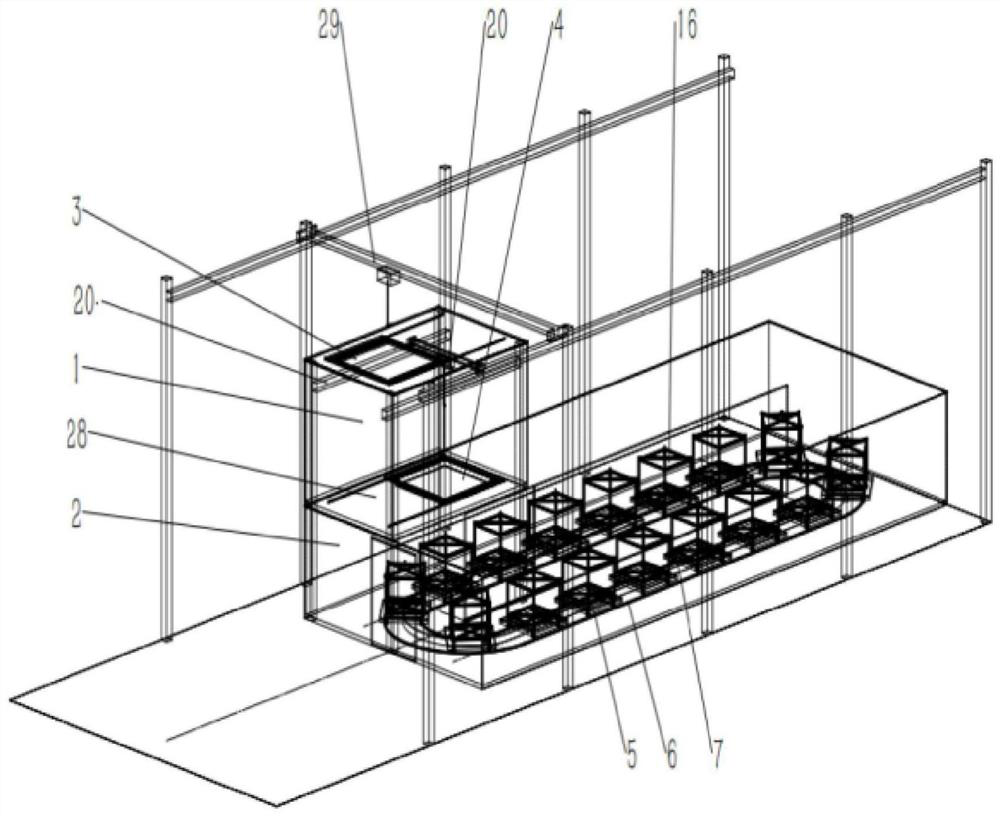

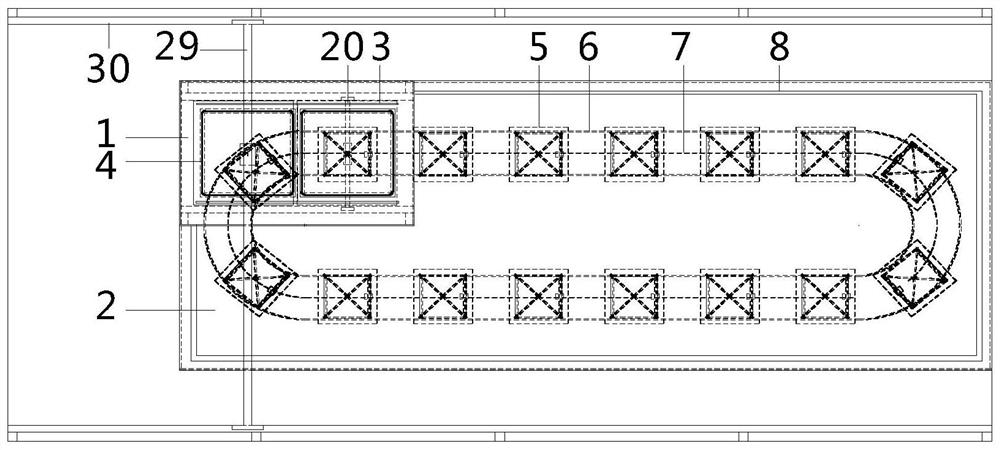

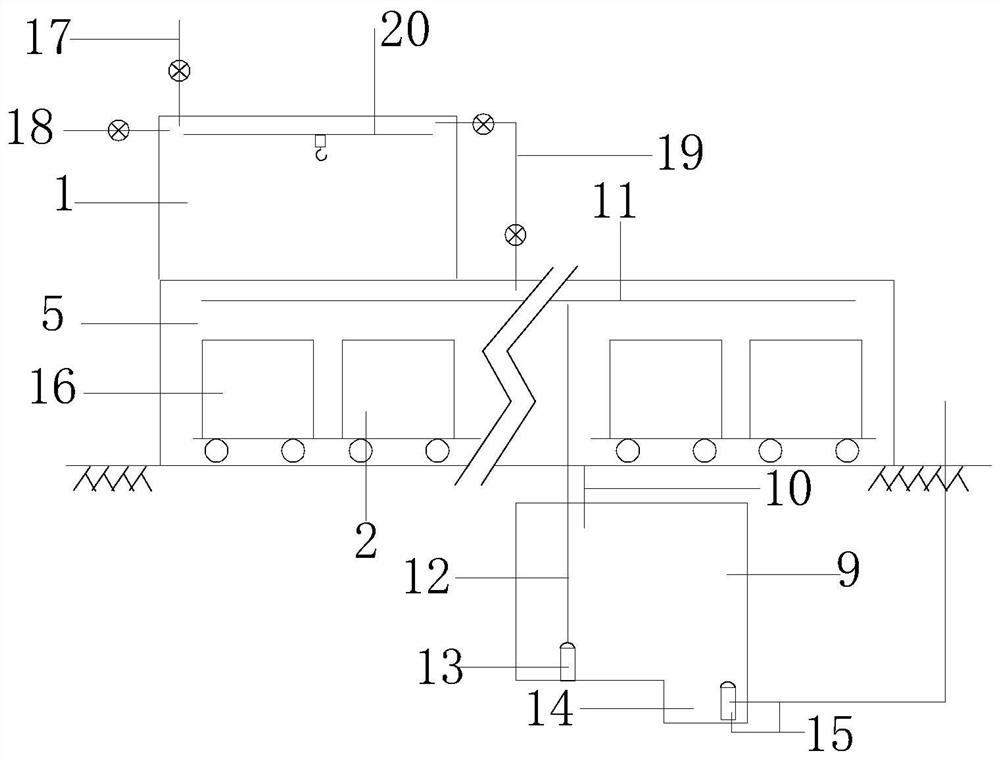

[0013] Tanks and carrying facilities, gas-liquid pipelines, automatic operation control systems and electrical actuators using continuous feeding and discharging fermentation equipment, dry biogas fermentation system for dry organic solid waste, including the used inlet and outlet bins, fermentation bins, biogas Operation of liquid sludge sedimentation tank and biogas fermentation system: see Figure 7 , the operation automatic control system remote crane 29 lifts the material square box 16 into the feed bin 1, and opens the feed bin sealing window 3, lifts the material square box 16 to the transfer platform 28, and the crane 29 leaves the feed bin 1 , close the sealing window 3 of the feeding bin, charge carbon dioxide gas into the feeding bin 1 through the inflation pipe 17, and discharge the air in the feeding bin through the exhaust pipe 18 at the same time, until it is confirmed that there is no oxygen in the bin, stop charging and exhausting; The internal crane 20 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com