Rapid sintering equipment for dynamically loading coupling alternating current and sintering method

A dynamic loading and rapid sintering technology, applied in the field of sintering, can solve the problems of unsatisfactory elimination of nano-powder hard agglomeration, achieve good industrial application prospects, reduce sintering temperature, and promote the effect of particle rearrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

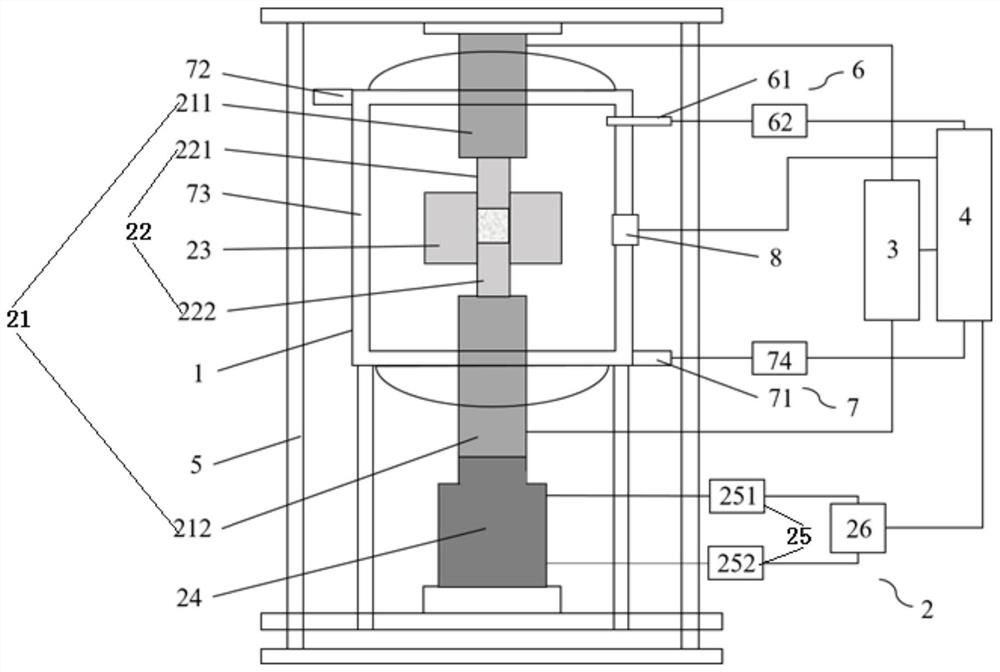

[0043] Such as Figure 1-3 As shown, this embodiment provides a dynamic loading coupled alternating current rapid sintering equipment, including the following components:

[0044] A furnace frame 5, a furnace body 1 is arranged in the furnace frame 5, and an airtight pressure-holding cabin is formed in the furnace body 1;

[0045] The dynamic loading system 2 includes a dynamic loading generation part and a dynamic loading control part, the dynamic loading generation part is set in the pressure holding cabin, and is used for pressurizing and heating the sintered material; the dynamic loading control part is set outside the pressure holding cabin, and the dynamic loading The output terminal of the load control part is connected with the dynamic load generation part, and is used for outputting the coupled total dynamic load to the dynamic load generation part;

[0046] The sintering control system 4 is arranged outside the pressure holding cabin, the output end of the sintering...

Embodiment 2

[0060] Such as Figure 1-3 As shown, this embodiment relates to a sintering method of a fast sintering device dynamically loaded with coupled alternating current, including the following steps:

[0061] a Check the rapid sintering equipment and put in the materials to be sintered;

[0062] b Input the sintering process parameters through the sintering control system 4;

[0063] c According to the requirements of the sintering process parameters, the sintering control system 4 vacuumizes the pressure holding chamber or injects gas (such as argon, nitrogen, etc.) through the atmosphere control system 6, and starts to operate after the air pressure in the pressure holding chamber reaches the set value Sintering procedure;

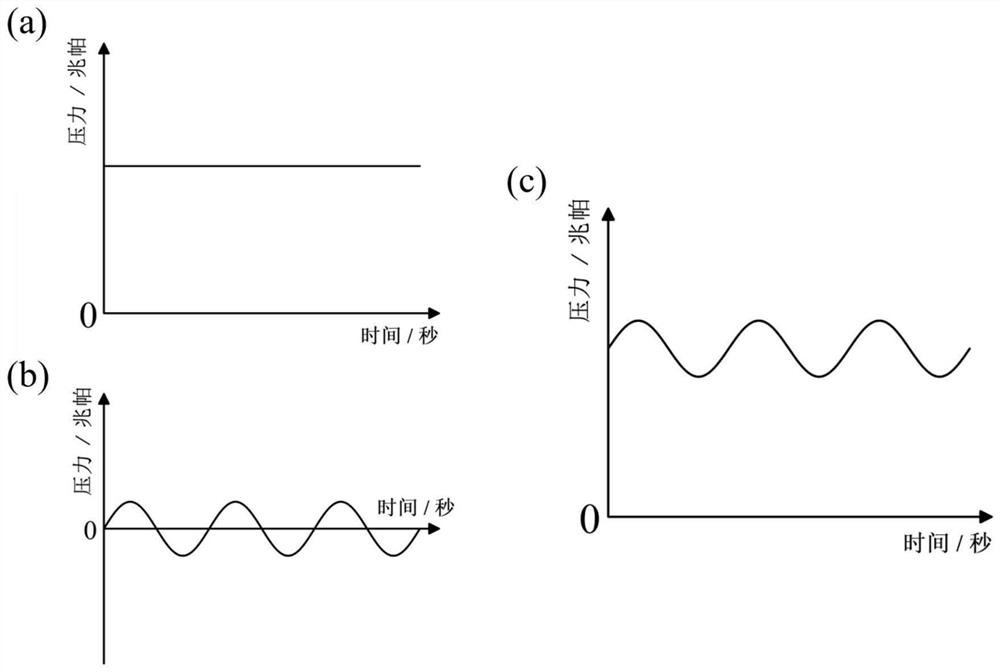

[0064] d According to the requirements of the sintering process parameters, the parameters of the total dynamic loading are adjusted and applied through the sintering control system 4 and the dynamic loading system 2;

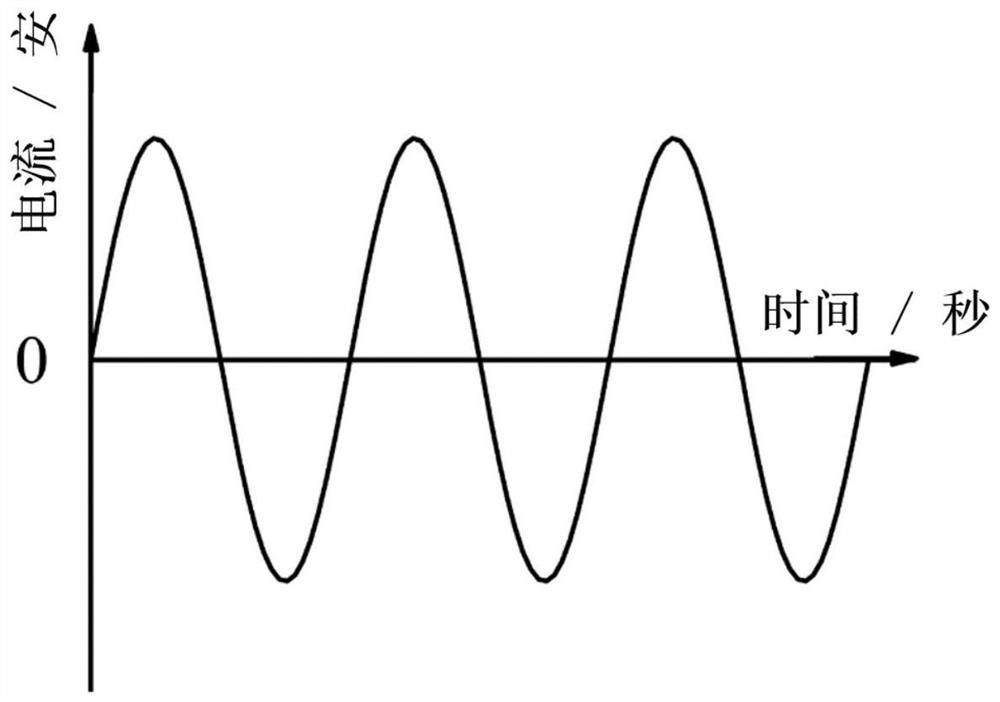

[0065] e According to the requirement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com