A polyunsaturated carboxylic acid group controllable cross-linking binder and a lithium ion battery containing the binder

A binder and unsaturated technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of complex batching process and reduced binder solubility, and achieve excellent adhesion and reduce slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

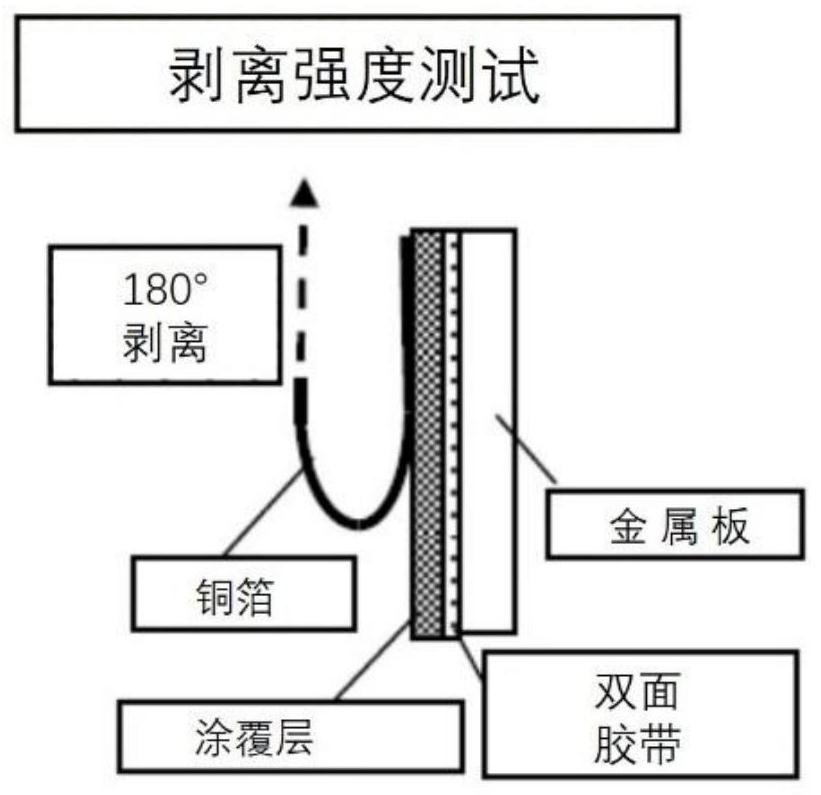

[0084] [Preparation of pole piece]

[0085] The present invention also provides a preparation method for the above-mentioned pole piece, which includes:

[0086] a) preparing the binder system, including: preparing a matrix component, which is an unsaturated carboxylic acid-based polymer; preparing a doping component, which is a bisoxazoline small molecular.

[0087] In a specific embodiment, the preparation method of the pole piece includes the following steps:

[0088] a) preparing the binder system, including: preparing a matrix component, which is an unsaturated carboxylic acid-based polymer; preparing a doping component, which is a bisoxazoline small molecular;

[0089] b) uniformly mixing the active material, the conductive agent, and the binder system in step a) to obtain a slurry;

[0090]c) coating the slurry in step b) on at least one surface of the current collector, and drying to obtain the pole piece.

[0091] In a specific embodiment, the pole piece is a pos...

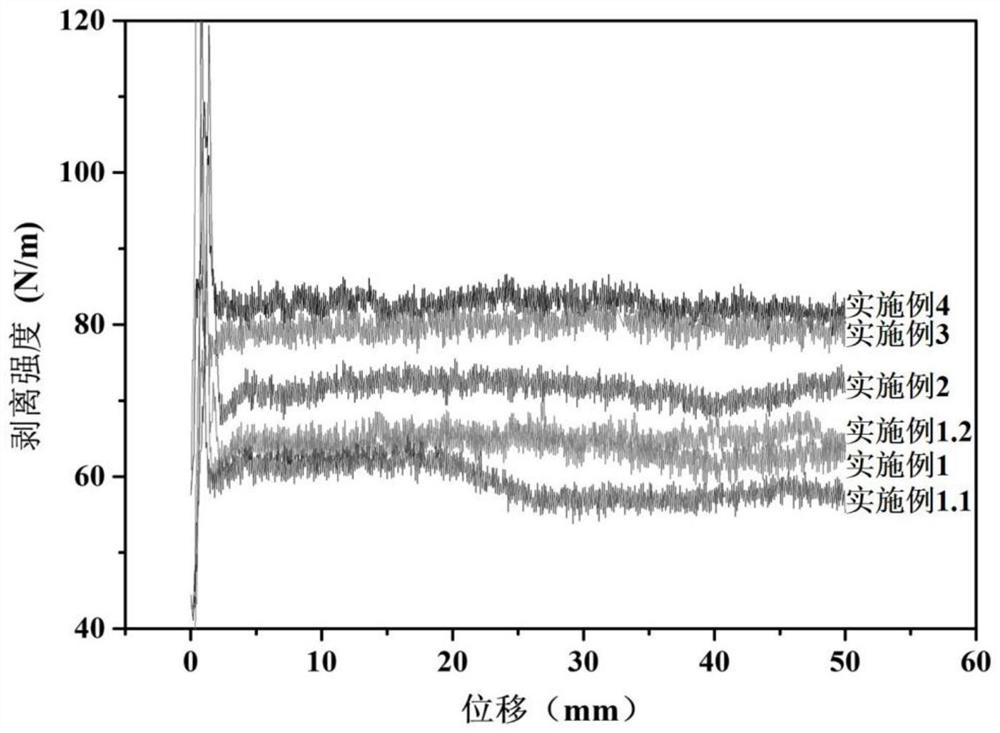

Embodiment 1

[0118] Preparation of the binder system:

[0119] Take 10g of acrylic acid and disperse it in 190g of deionized water, stir it mechanically at 800rpm, raise the temperature to 40°C, keep it warm for 30min, blow in nitrogen, add 0.05g of sodium persulfate and 0.2g of sodium bisulfite, and continue the reaction for 10h. After the reaction, cool down to 30°C to obtain an unsaturated carboxylic acid-based polymer, then add 2g of the bisoxazoline small molecule shown in formula (II), and stir mechanically at 500rpm for 30min to obtain a binder system with a viscosity of 3500mPa ·s.

[0120] The prepared unsaturated carboxylic acid-based polymer was characterized, and the weight-average molecular weight was 1 million; the decomposition temperature was 325° C. (TG test), and the glass transition temperature was 106° C. (DSC test).

[0121] Preparation of the negative electrode sheet: the negative electrode active material silicon-based / graphite composite negative electrode material ...

Embodiment 11

[0125] The difference from Example 1 is that the amount of bisoxazoline small molecules added is 1 g, and other conditions are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com