Radiation refrigeration film, preparation method thereof and product

A technology of radiation refrigeration and reflective layer, applied in refrigerators, refrigeration and liquefaction, chemical instruments and methods, etc., can solve the problems of high cost, poor refrigeration effect of refrigeration film, complex process, etc., to improve reflectivity and refrigeration. effect, the effect of improving the anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

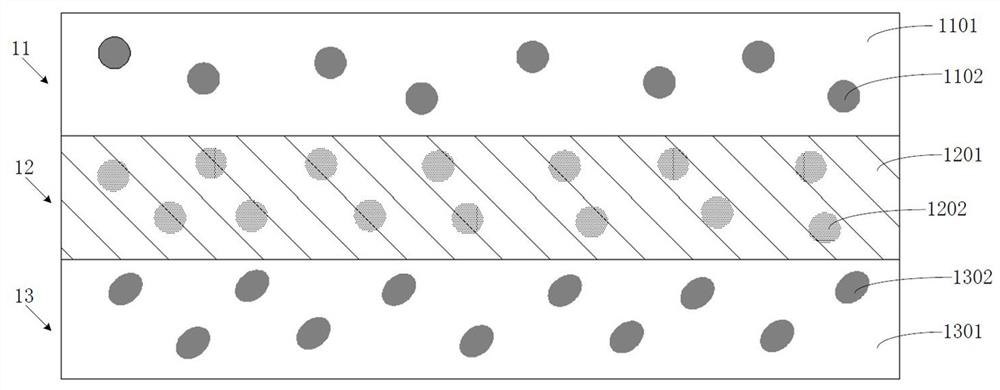

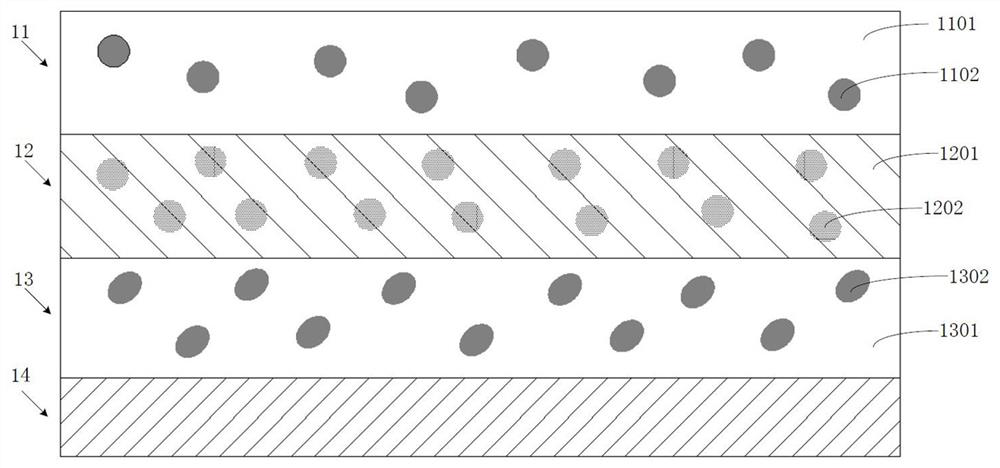

[0066] Another embodiment of the present invention provides a method for preparing a radiant cooler film, the process comprising the steps of:

[0067] The first reflective layer 1101 of the body 1102 first filler material mixed with the granulated to obtain a first mixture;

[0068] The base layer and the radiant cooler the raw material mixture granulated filler 1202 1201, to give the radiation refrigerant mixture;

[0069] The second reflective layer material and the second body 1301 1302 mixing granulated filler, to obtain a second mixture;

[0070] The first mixture, cooling the mixture and a second radiation mix are extruded and formed into a first mixture, cooling the mixture and a second radiation mix are sequentially stacked structure obtained cast material;

[0071] The casting tape casting stream. To give the first reflective layer 11, the membrane 12 and the radiation cooling the second reflective layer 13 are sequentially laminated layers of radiation cooling function....

Embodiment 1

[0079] In this embodiment the first reflective layer has a thickness of 20 m, a first reflective layer of PMMA main body, the first filler is perlite, the first filler particle diameter of 5 m, a first filler comprising a first reflective layer mass percentage of 25% .

[0080] Radiation cooling function a layer thickness of 50 m, the base layer is a layer of radiation cooling function PMMA layer, a transparent silica filler radiation cooling, radiation cooling filler particle diameter of 10 m, the radiation quality of the radiation cooling filler comprising cooling function layer is 2 percent %.

[0081] The second reflective layer has a thickness of 25 m, as the second reflective layer PMMA main body, a second transparent filler is titanium dioxide, the particle size of the second filler is 3 m, the second filler comprises a second reflective layer mass percentage is 40%.

Embodiment 2

[0083] In this embodiment the first reflective layer with a thickness of 15 m, the first reflective layer is a PE main body, the first filler is quartz powder, the first filler particle diameter of 10 m, a first filler comprising a first reflective layer mass percentage of 10% .

[0084] Radiation cooling function layer has a thickness of 25 m, the base layer is a layer of radiation cooling function PE layer, a transparent filler is silicon carbide radiant cooling, radiation cooling filler particle diameter of 20 m, mass of filler comprises a radiation cooling radiant cooler percent functional layer is 1% .

[0085] The second reflective layer has a thickness of 30 m, as the second reflective layer PE main body, barium sulfate as second filler, second filler particle diameter of 10 m, the second filler comprises a second reflective layer mass percentage is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com