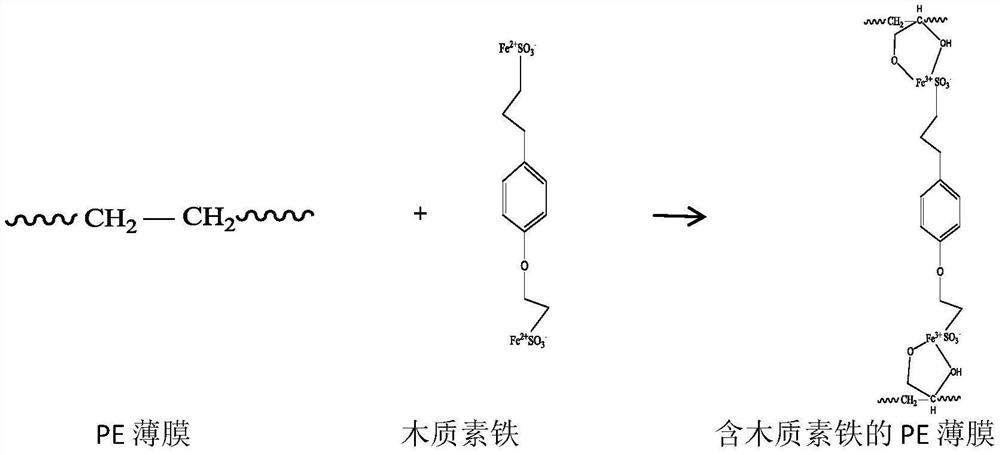

PE film material containing lignin iron, and synthesis method thereof

A thin film material, lignin technology, applied in the field of polymer materials, to achieve the effect of mild reaction conditions, good mechanical properties, and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

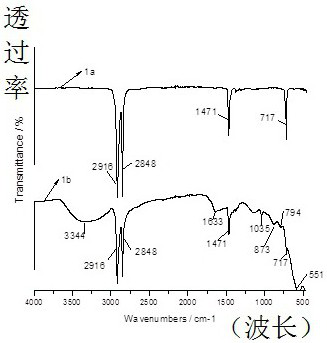

[0021] Dissolve 4g of sodium hydroxide in deionized water, immerse 2g of PE film in the sodium hydroxide solution, then put it into an ultrasonic reactor, control the temperature at 60°C for 8 hours, take out the PE film after the reaction, and wash it with deionized water Clean; add 25g of lignin iron into deionized water, immerse the cleaned PE film in the lignin iron solution, and react at a temperature of 50°C for 6 hours. After the reaction, take out the PE film, dry at 90°C to constant weight, and Rinse with water and dry at room temperature. After the dried PE film was sampled and digested, the total iron content in the reaction product was measured by inductively coupled plasma atomic emission spectrometry to be 50.7mg / g film, and the breaking force was 2.1N. The infrared spectrum of the reaction product is as figure 1 As shown, there is a significant change compared with the infrared spectrum of PE film, 2916cm -1 、2848cm -1 、1471cm -1 、717cm -1 The absorption pe...

Embodiment 2

[0023] Dissolve 4g of sodium hydroxide in deionized water, immerse 2g of PE film in the sodium hydroxide solution, then put it into an ultrasonic reactor, control the temperature at 70°C for 12 hours, take out the PE film after the reaction, and wash it with deionized water Clean; add 100g of lignin iron into deionized water, immerse the cleaned PE film in the lignin iron solution, and react at a temperature of 80°C for 10 hours. After the reaction, take out the PE film, dry at 110°C to constant weight, Rinse with water and dry at room temperature. After the dried PE film was sampled and digested, the total iron content in the reaction product was measured by inductively coupled plasma atomic emission spectrometry to be 759.6mg / g film, and the breaking force was 1.7N. The change situation of reaction product infrared spectrum is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking force | aaaaa | aaaaa |

| Breaking force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com