A continuous fluidized calcination system and method for pearlescent materials

A pearlescent material and fluidization technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment processing, etc., can solve the problems of unstable quality control of pearlescent material calcination, affecting the quality of pearlescent materials, and reducing the moving speed of conveyor belts. , to achieve the effect of good calcination effect, fast and efficient calcination, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

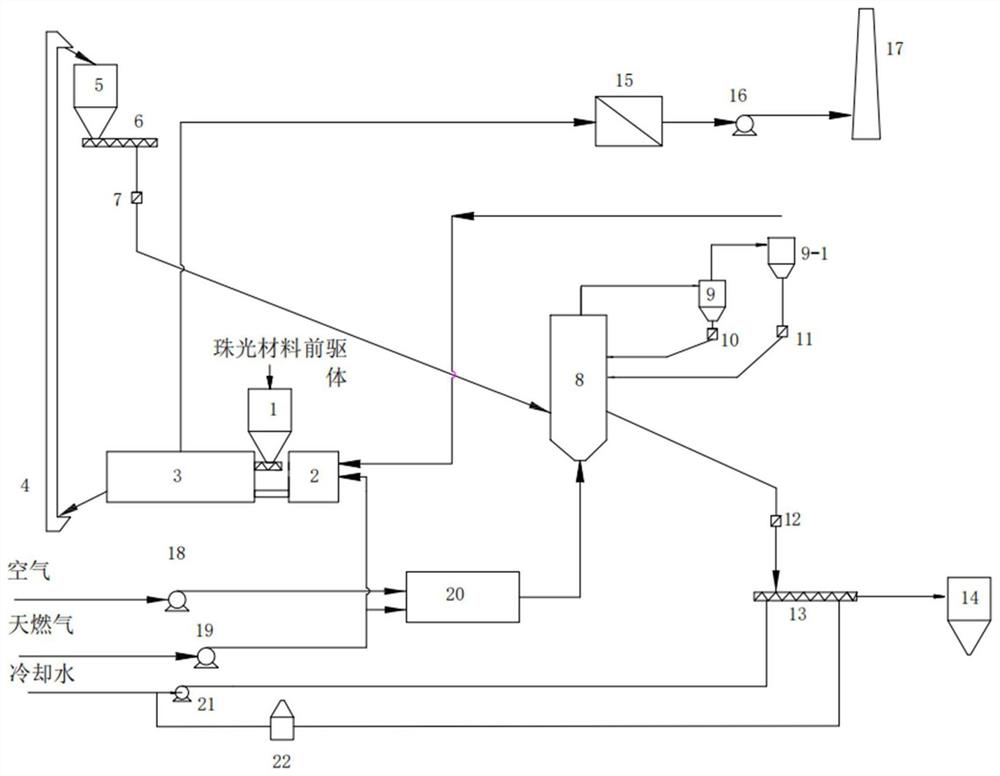

[0029] Such as figure 1 As shown, a system for continuous fluidized calcination process of pearlescent materials, the system includes a raw material bin 1, a hot blast stove 2, a rotary dryer 3, an elevator 4, a top bin 5, and a feeding screw 6 connected in sequence , feed valve 7, fluidized bed 8, primary cyclone separator 9, secondary cyclone separator 9-1, one-point return valve 10, two-point return valve 11, discharge valve 12, water-cooled screw 13, product Silo 14, bag filter 15, induced draft fan 16, chimney 17, air fan 18, natural gas fan 19, combustion chamber 20, water pump 21 and cooling tower 22;

[0030] In the system, the discharge port of the raw material bin 1 is connected with the feed port of the rotary dryer 3, the air inlet of the hot blast stove 2 is connected with the gas outlet of the natural gas blower 19 and the secondary cyclone separator 9-1, The air inlet of the rotary dryer 3 is connected to the gas outlet of the hot blast stove 2, the discharge p...

Embodiment 2

[0033] A method for the continuous fluidized calcination process of pearlescent materials, comprising the steps of:

[0034] 1) The pearlescent material precursor powder enters the rotary dryer 3 through the raw material bin 1 and enters the elevator 4, the top bin 5 and the feeding screw 6 in turn, and enters the fluidized bed 8 through the feeding valve 7; the fluidized bed 8 is discharged The powder entrained in the high-temperature exhaust gas is collected by the first-stage cyclone separator 9 and the second-stage cyclone separator 9-1, and then enters the fluidized bed 8 through the first-point return valve 10 and the second-point return valve 11; The material is discharged from the discharge port of the fluidized bed 8, enters the water-cooled screw 13 to cool through the discharge valve 12, and finally enters the product silo 14 for storage;

[0035] 2) The fluidization wind is produced by the combustion of natural gas and air in the combustion chamber 20, and the oxid...

Embodiment 3

[0040] Using the method described in Example 2, the silver-white series pearlescent material precursor powder with a water content of 5wt% enters the rotary dryer 3 through the raw material bin 1 and enters the elevator 4, the top bin 5 and the feeding screw 6 in turn, Enter the fluidized bed 8 through the feed valve 7; the fluidized air is produced by the combustion of natural gas and air in the combustion chamber 20, and the oxidative hot flue gas produced by the combustion enters the fluidized bed through the inlet of the fluidized bed 8 for Fluidization and calcination of the pearlescent material precursor in the fluidized bed, the calcination temperature is 550°C, and the calcination time is 60 minutes; after passing through the primary cyclone separator 9 and the secondary cyclone separator 9-1, it enters the hot blast furnace 2 for supplementary heat combustion , and then enter the rotary dryer 3 to dry the uncalcined pearlescent material precursor, then enter the bag fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com