Multifunctional waterborne epoxy acrylic resin composition and preparation method thereof

A technology of epoxy acrylic resin and resin composition, which is applied in the field of coatings, can solve the problems of water-based acrylic resin application field limitations, water resistance is not long-term, poor anti-sticking property, etc., to improve storage stability, easy to water-based, excellent performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

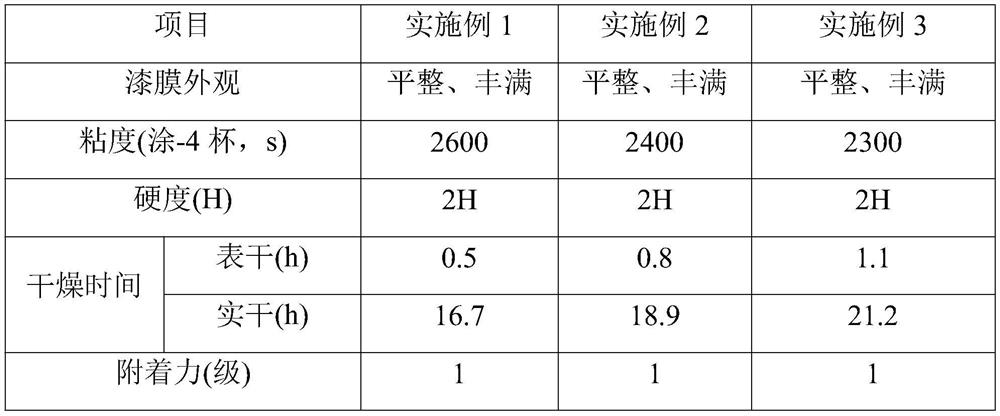

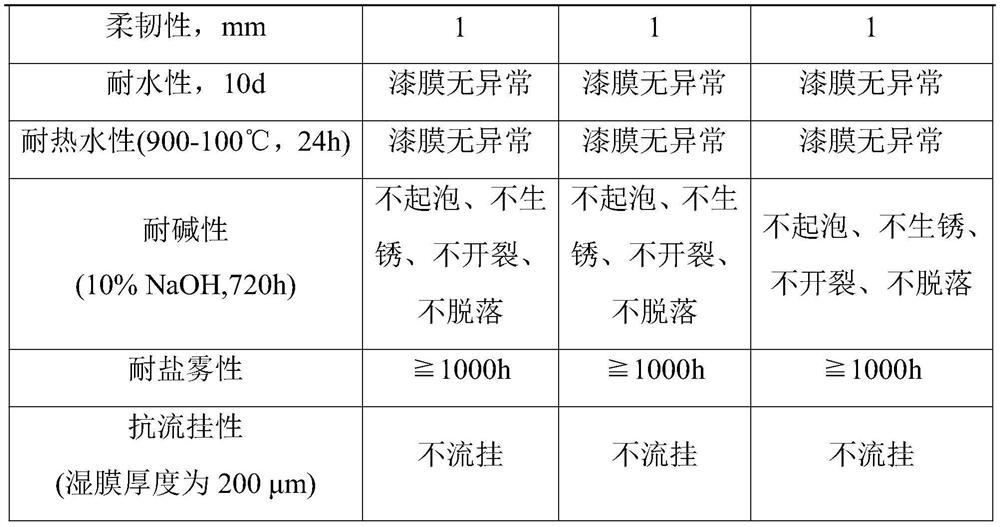

Examples

Embodiment 1

[0021] A preparation method of multifunctional water-based epoxy acrylic resin composition, prepared by the following steps:

[0022] Step 1: Mix bisphenol A epoxy resin with a molar ratio of 1:0.8 and a monobasic acid or a dibasic acid, use a mixture of propylene glycol ether and cyclohexanone with a mass ratio of 1:1 as a solvent, add a catalyst, and reflux Heating the material to 160°C under the state, keeping it warm for 2.5h, when the acid value drops below 1mgKOH / g, stop heating, and obtain the modified bisphenol A epoxy resin;

[0023] Step 2: Add 7 parts of acrylic acid, 5 parts of styrene, 4 parts of acrylonitrile and 45 parts of water into the reaction kettle in sequence, add emulsifier to emulsify for 28 minutes; add 1.5 parts of initiator into water to dissolve, add 30% of the initiator solution mass dropwise Into the reaction kettle, add dropwise for 1.5 hours, and at the same time heat the material to 75°C, stir and react for 1.5 hours to obtain emulsion A;

[0...

Embodiment 2

[0027] A preparation method of multifunctional water-based epoxy acrylic resin composition, prepared by the following steps:

[0028] Step 1: Mix bisphenol A type epoxy resin with a molar ratio of 1:1.0 and a monobasic acid or a dibasic acid, use a mixture of propylene glycol ether and cyclohexanone with a mass ratio of 1:1 as a solvent, add a catalyst, and reflux Heating the material to 155°C under the state, keeping it warm for 3 hours, when the acid value drops below 1mgKOH / g, stop heating, and obtain the modified bisphenol A epoxy resin;

[0029] Step 2: Add 8 parts of acrylic acid, 6 parts of styrene, 5 parts of acrylonitrile and 55 parts of water into the reaction kettle in sequence, add emulsifier to emulsify for 25 minutes; add 2 parts of initiator into water to dissolve, add 30% of the initiator solution mass Into the reaction kettle, add dropwise for 1 hour, heat the material to 80°C at the same time, stir and react for 1.2 hours to obtain emulsion A;

[0030] Step ...

Embodiment 3

[0033] A preparation method of multifunctional water-based epoxy acrylic resin composition, prepared by the following steps:

[0034] Step 1: Mix bisphenol A type epoxy resin with a molar ratio of 1:1.0 and a monobasic acid or a dibasic acid, use a mixture of propylene glycol ether and cyclohexanone with a mass ratio of 1:1 as a solvent, add a catalyst, and reflux Heating the material to 170°C under the state, keeping it warm for 3.5h, when the acid value drops below 1mgKOH / g, stop heating, and obtain the modified bisphenol A epoxy resin;

[0035] Step 2: Add 6 parts of acrylic acid, 4 parts of styrene, 4 parts of acrylonitrile and 60 parts of water into the reaction kettle in sequence, add emulsifier to emulsify for 26 minutes; add 1.5 parts of initiator into water to dissolve, add 30% of the initiator solution mass dropwise Into the reaction kettle, add dropwise for 1.5 hours, and at the same time heat the material to 80°C, stir and react for 1.0 hours to obtain emulsion A; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com