Preparation method of nano zirconium oxide hollow spheres

A technology of nano-zirconia and hollow spheres, which is applied in the direction of zirconia and nanotechnology, can solve the problems of inability to prepare single-phase zirconia powder, unfavorable large-scale industrialization, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

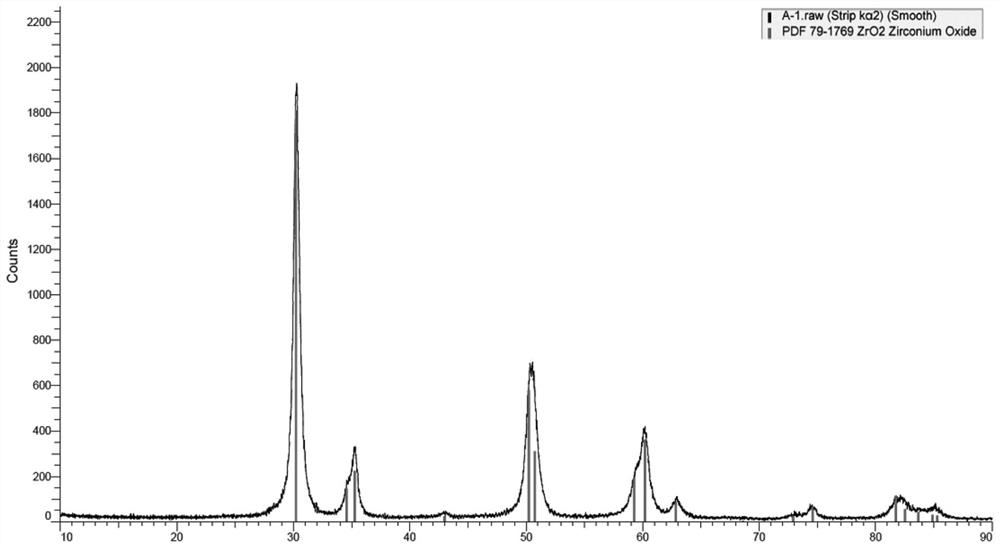

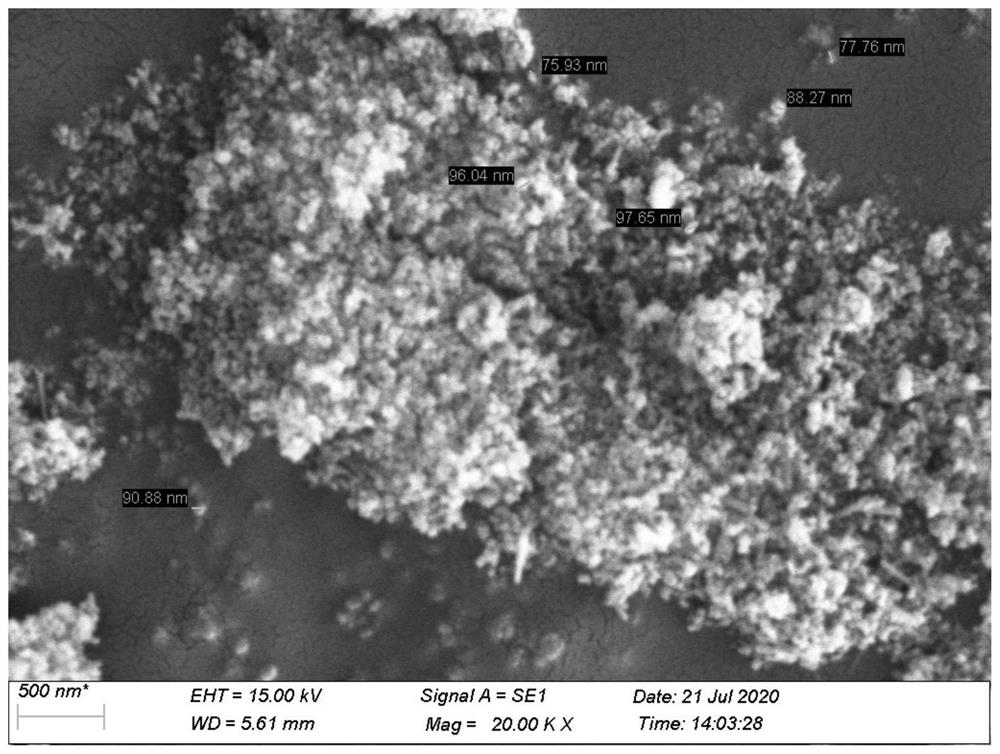

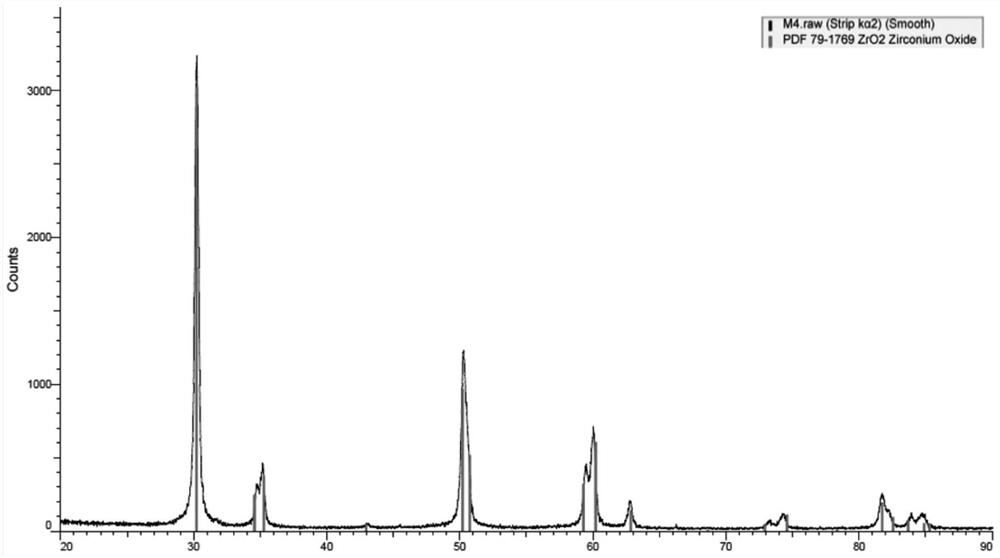

Image

Examples

Embodiment 1

[0050] Embodiment one: do not add complexing agent

[0051] Step 1.1, preparation of solution A, mixing and stirring water-soluble zirconium oxychloride, water-soluble yttrium nitrate, and deionized water in a molar ratio of 1:0.05:60 to obtain a homogeneous solution A;

[0052] Step 1.2, the preparation of solution B, mixing and stirring potassium hydroxide and deionized water according to the molar ratio of 1:55, to obtain a homogeneous solution B;

[0053] Step 1.3, preparation of precursor suspension, drop solution A into solution B at a rate of 10 ml / min, and keep stirring for 2 hours to obtain precursor suspension;

[0054] In step 1.4, a composite mineralizer composed of triethanolamine and potassium acetate with a molar ratio of 1:1 is added to the precursor suspension obtained in step 3, and the amount of the mineralizer added is the same as that of the soluble salt (ie soluble zirconium salt and water-soluble salt). The total amount of active yttrium salt) the mol r...

Embodiment 2

[0058] Embodiment two: add complexing agent

[0059] Step 2.1, preparation of solution A, mixing and stirring water-soluble zirconium oxychloride, water-soluble yttrium chloride, and deionized water in a molar ratio of 1:0.05:60 to obtain a homogeneous solution A;

[0060] Step 2.2, preparation of solution B, mixing and stirring potassium hydroxide and deionized water according to a molar ratio of 1:40, to obtain a homogeneous solution B;

[0061] Step 2.3, the preparation of solution C, the complexing agent that molar ratio is 3:7 tartaric acid, citric acid composition is added in B solution, and wherein complexing agent addition and potassium hydroxide molar ratio are 1:8;

[0062] Step 2.4, preparation of precursor suspension, drop solution A into solution C at a rate of 9 ml / min, and keep stirring for 2 hours to obtain a precursor suspension;

[0063] In step 2.5, a composite mineralizer composed of triethanolamine and potassium acetate with a molar ratio of 1:1 is added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com