Amino acid-containing organic liquid fertilizer and preparation method thereof

A liquid fertilizer and amino acid technology, applied in organic fertilizers, organic phosphate fertilizers, liquid fertilizers, etc., can solve the problems of insufficient nutrient content, ineffective increase in production, low fertilizer utilization rate, etc., achieve strong reproductive physiological activity, and promote photosynthesis , Increase the effect of nutritional content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

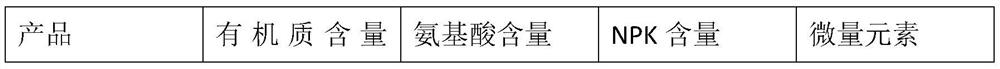

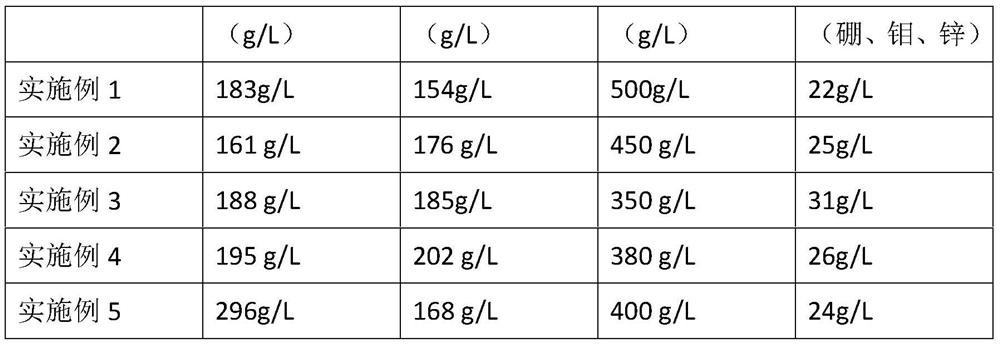

Embodiment 1

[0029] An amino acid-containing organic liquid fertilizer, its components include the following raw materials in parts by weight: 80 parts of potassium fulvic acid, 400 parts of potassium polyphosphate, 130 parts of glycine, 80 parts of phenylalanine, 100 parts of methionine, a- 120 parts of ketoglutaric acid, 120 parts of pyruvic acid, 350 parts of soybean fermentation concentrate, 120 parts of casein phosphopeptide, 45 parts of sodium octaborate tetrahydrate, 20 parts of ammonium molybdate, 70 parts of zinc sulfate, 280 parts of trehalose and 20 parts of complexed titanium.

[0030] Its preparation method comprises the following steps:

[0031] S1: Soybeans are smashed and boiled and put into the fermentation tank, inoculated with 4% compound bacteria and 2.3% compound enzyme, the weight ratio of each component in the compound bacteria species: 65 parts of Bacillus amyloliquefaciens, 35 parts of Bacillus licheniformis part, 50 parts of Bacillus subtilis; the weight ratio of...

Embodiment 2

[0038] An amino acid-containing organic liquid fertilizer, its components include the following raw materials in parts by weight: 90 parts of potassium fulvic acid, 350 parts of potassium polyphosphate, 120 parts of glycine, 100 parts of phenylalanine, 120 parts of methionine, a- 130 parts of ketoglutaric acid, 100 parts of pyruvic acid, 380 parts of soybean fermentation concentrate, 100 parts of casein phosphopeptide, 35 parts of sodium octaborate tetrahydrate, 18 parts of ammonium molybdate, 60 parts of zinc sulfate, 250 parts of trehalose and Complex titanium 15 parts.

[0039] Its preparation method comprises the following steps:

[0040] S1: Soybeans are smashed and boiled and put into the fermentation tank, inoculated with 3.8% compound bacteria and 3.2% compound enzyme, the weight ratio of each component in the compound bacteria species: 65 parts of Bacillus amyloliquefaciens, 35 parts of Bacillus licheniformis parts, 50 parts of Bacillus subtilis; the weight ratio of ...

Embodiment 3

[0047] An amino acid-containing organic liquid fertilizer, its components include the following raw materials in parts by weight: 85 parts of potassium fulvic acid, 420 parts of potassium polyphosphate, 130 parts of glycine, 80 parts of phenylalanine, 130 parts of methionine, a- 120 parts of ketoglutaric acid, 110 parts of pyruvic acid, 330 parts of soybean fermentation concentrate, 120 parts of casein phosphopeptide, 42 parts of sodium octaborate tetrahydrate, 15 parts of ammonium molybdate, 70 parts of zinc sulfate, 280 parts of trehalose and 22 parts of complex titanium.

[0048] Its preparation method comprises the following steps:

[0049] S1: Soybeans are smashed and boiled and put into the fermentation tank, inoculated with 4.8% compound bacteria and 2.5% compound enzyme, the weight ratio of each component in the compound bacteria species: 70 parts of Bacillus amyloliquefaciens, 32 parts of Bacillus licheniformis part, 28 parts of Bacillus subtilis; the weight ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com