A kind of preparation method and application of graphite phase carbon nitride nanotube photoelectrode coated with graphene roll

A graphite phase carbon nitride, graphene roll technology, applied in electrophoretic plating, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problem of limited improvement of photo-generated electron-hole separation efficiency, and achieve the effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

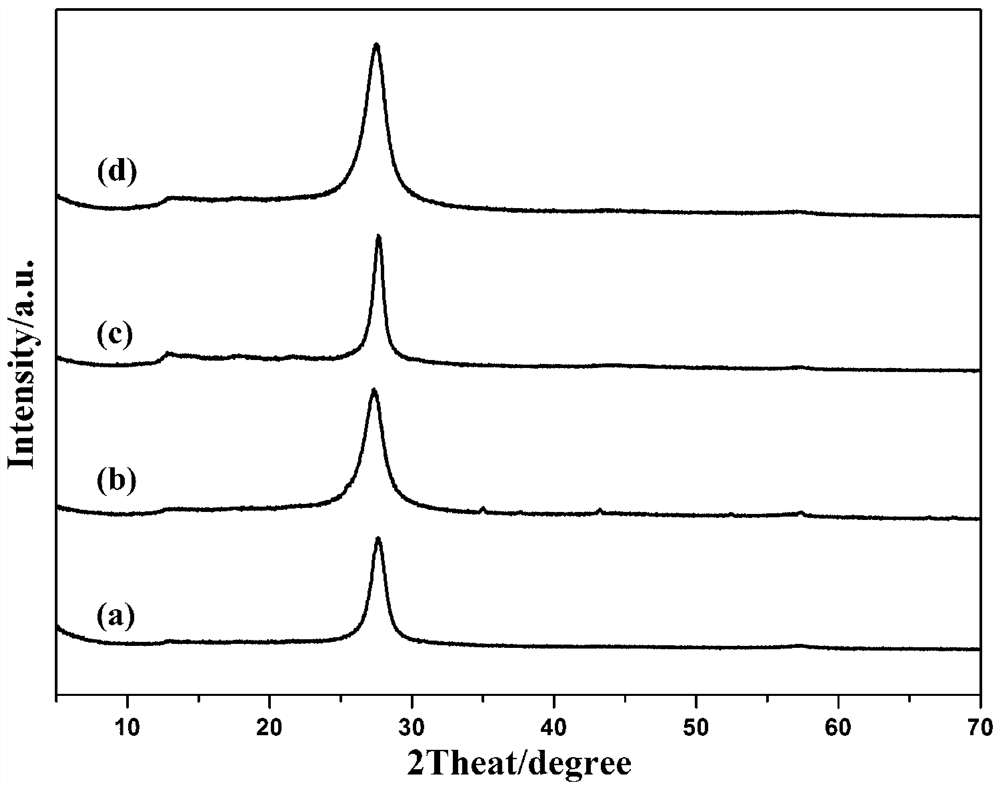

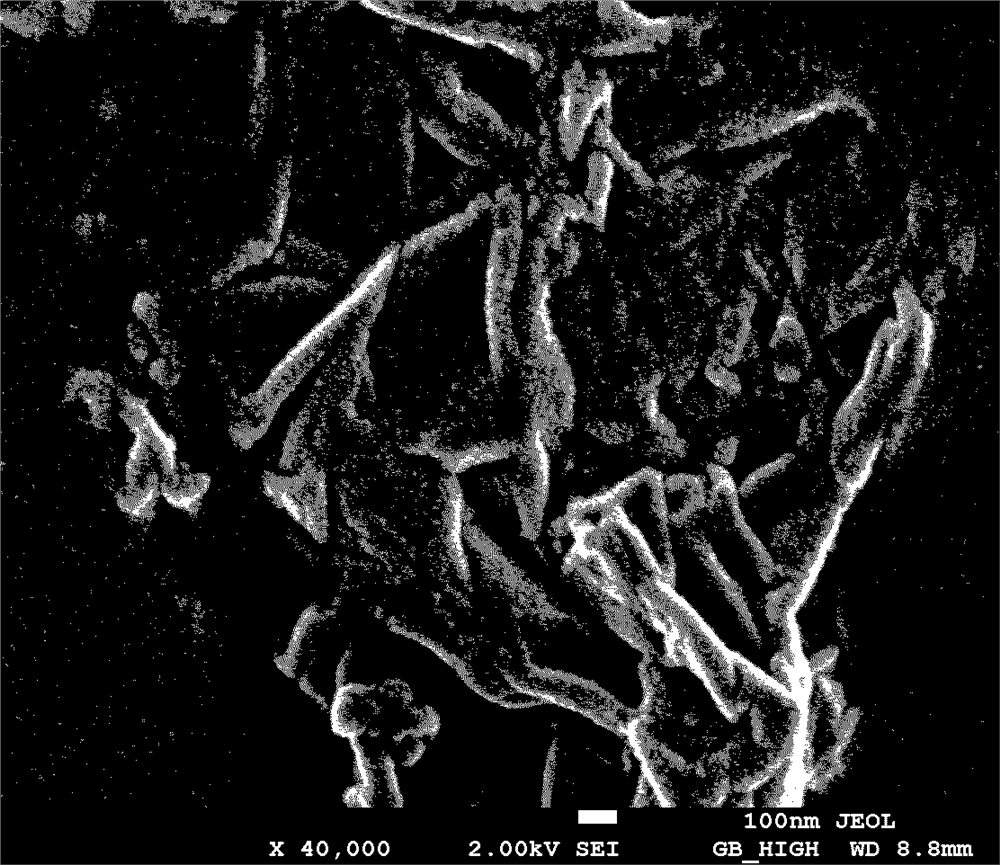

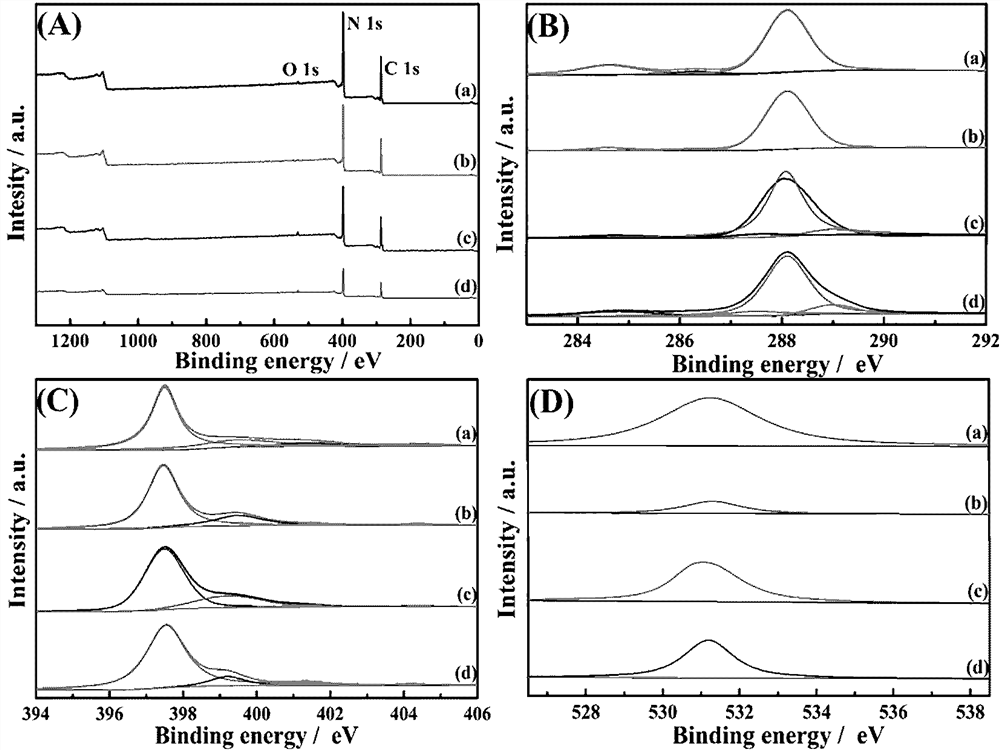

[0035] A preparation method of graphene roll-coated graphite phase carbon nitride nanotube photoelectrode, the method will thermally decompose melamine to obtain g-C 3 N 4 Nanotubes form a dispersion liquid with graphene oxide at a mass ratio of 1:1, and undergo quenching treatment to obtain graphene oxide curl-coated C 3 N 4 The nanotubes are deposited by electrophoresis and thermally reduced at 350°C to obtain graphene roll-coated graphitic phase carbon nitride nanotube photoelectrodes, which specifically includes the following steps:

[0036] (1) Weigh 5 g of melamine, put it into a corundum ark after grinding, place the ark in a shaker, and shake it at a medium speed for 10 minutes;

[0037] (2) Cover the ark and move it into a tube furnace. Under the protection of nitrogen, it will be calcined at 10°C / min to 500°C for 2 hours, then at 1°C / min to 530°C for 2 hours, and it will be nitrided after natural cooling. carbon nanotubes;

[0038] (3) Weigh 0.1g of graphene oxid...

Embodiment 2

[0044] A preparation method of graphene roll-coated graphite phase carbon nitride nanotube photoelectrode, the method will thermally decompose melamine to obtain g-C 3 N 4 Nanotubes form a dispersion liquid with graphene oxide at a mass ratio of 1:2, and undergo quenching treatment to obtain graphene oxide curl-coated C 3 N 4 The nanotubes are deposited by electrophoresis and thermally reduced at 350°C to obtain graphene roll-coated graphitic phase carbon nitride nanotube photoelectrodes, which specifically includes the following steps:

[0045] (1) Weigh 5 g of melamine, put it into a corundum ark after grinding, place the ark in a shaker, and shake it at a medium speed for 10 minutes;

[0046] (2) Cover the ark and move it into a tube furnace. Under the protection of nitrogen, it will be calcined at 10°C / min to 500°C for 2 hours, then at 1°C / min to 530°C for 2 hours, and it will be nitrided after natural cooling. carbon nanotubes;

[0047] (3) Weigh 0.1g of graphene oxid...

Embodiment 3

[0053] A preparation method of graphene roll-coated graphite phase carbon nitride nanotube photoelectrode, the method thermally decomposes melamine to obtain g-C 3 N 4 Nanotubes and graphene oxide are dispersed in deionized water according to the mass ratio of 2:1, and the graphene oxide curl-coated C is obtained after quenching treatment. 3 N 4 The nanotubes are deposited by electrophoresis and thermally reduced at 350°C to obtain graphene roll-coated graphitic phase carbon nitride nanotube photoelectrodes, which specifically includes the following steps:

[0054] (1) Weigh 5 g of melamine, put it into a corundum ark after grinding, place the ark in a shaker, and shake it at a medium speed for 10 minutes;

[0055] (2) Cover the ark and move it into a tube furnace. Under the protection of nitrogen, it will be calcined at 10°C / min to 500°C for 2 hours, then at 1°C / min to 530°C for 2 hours, and it will be nitrided after natural cooling. carbon nanotubes;

[0056] (3) Weigh 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com