Water-absorbing, range-extending, energy-saving and emission-reducing green aero-engine

An aero-engine, energy-saving and emission-reducing technology, which is applied to the cooling of engine components, machines/engines, and engines, can solve problems such as energy waste, environmental pollution, and fuel waste, and achieve the effect of slowing down thermal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

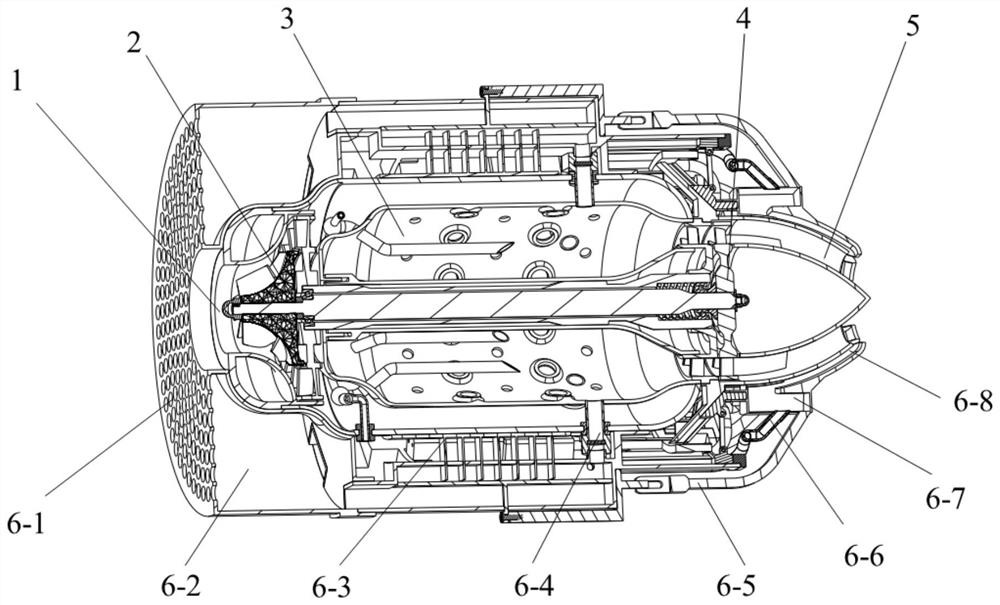

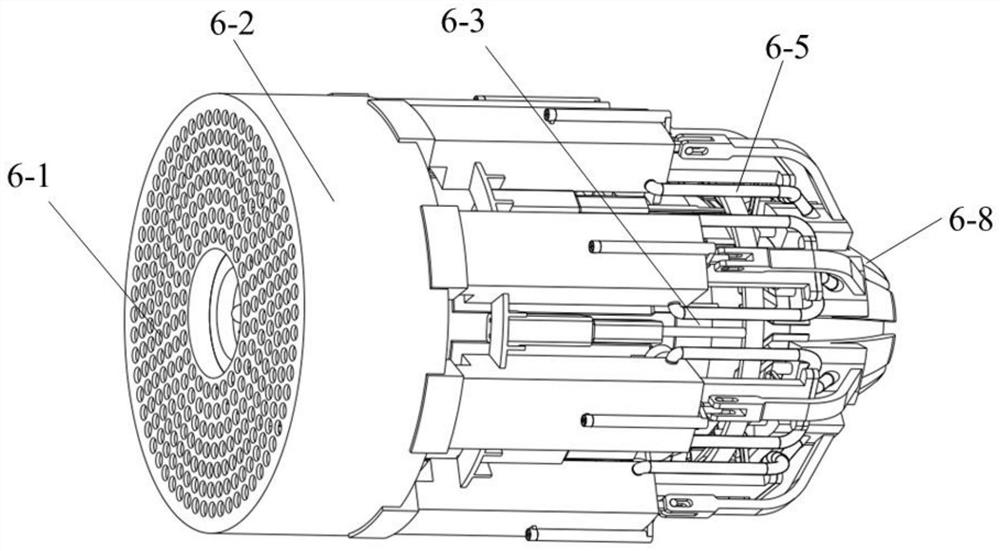

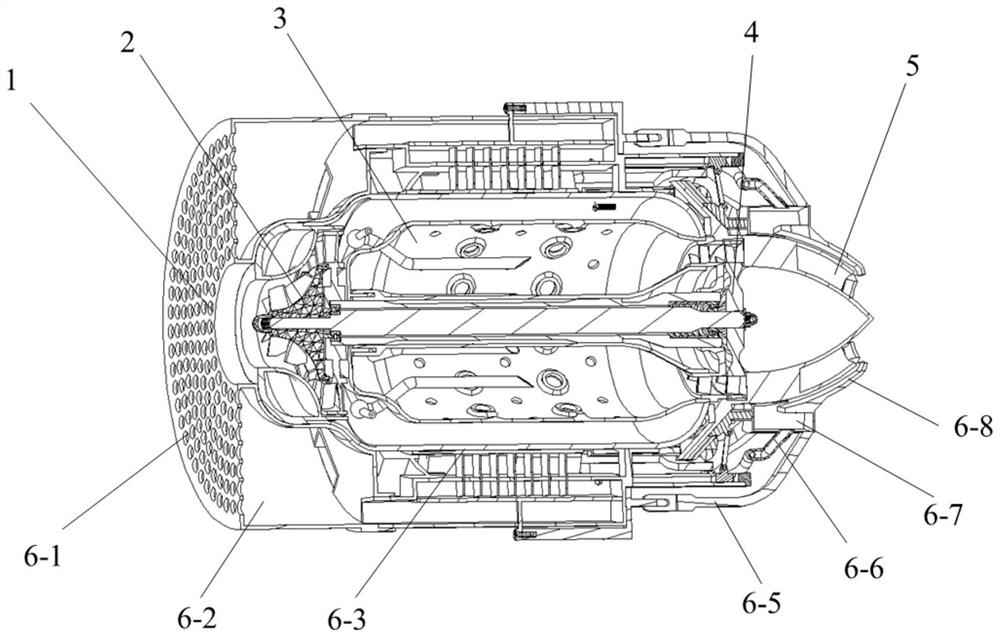

[0027]The present invention proposes a water-absorbing, range-extending, energy-saving and emission-reducing green aero-engine, which consists of an air inlet 1, a compressor 2, a combustion chamber 3, a turbine 4, an exhaust nozzle 5, and a water absorption and storage device, wherein the air inlet 1, the compressor system 2, the combustion chamber 3, the turbine 4, and the exhaust nozzle 5 are the original devices of the turbojet engine, and its positional relationship is that the air inlet 1 is located at the head of the engine, and the rear part of the air inlet 1 is the compressor 2 of the compressor system, and the air compressor Engine 2 links to each other with combustion chamber 3, and the end of combustion chamber 3 links to each other with the front end of turbine 4, and the rear of turbine 4 is exhaust gas nozzle 5. The main air intake 1 is the channel through which air enters the engine. When the aircraft is running, it forms convection with the air in the atmosphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com