Biological fermentation preparation method for flavored pigskin

A bio-fermentation and pigskin technology, applied in food science, functions of food ingredients, food drying, etc., can solve the problems of not fully considering the nutrition and flavor of fermented pigskin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

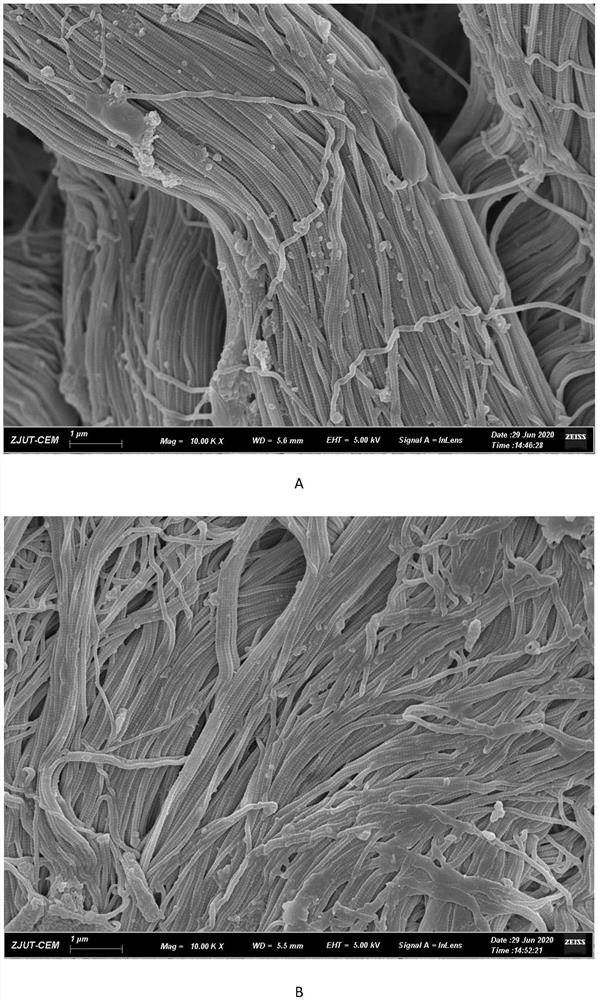

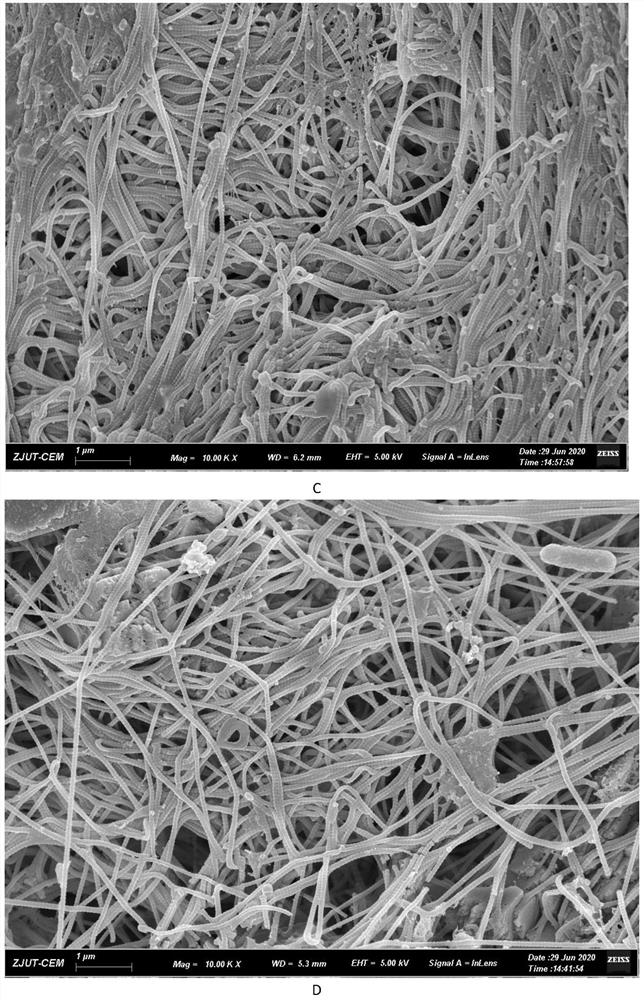

Image

Examples

Embodiment 1

[0054] (1) Pretreatment of pigskin:

[0055] Get fresh pigskin, wash it with water, scrape off excess fat and pig hair with a knife, cut it into small pieces of 3cm*3cm, wash it with water, and then sterilize it with 3% (w / w) food-grade hydrogen peroxide for 3 hours , washed repeatedly with clear water to obtain sterilized pigskin for later use.

[0056] (2) Preparation of inoculation solution A

[0057] Take 37.5g of potato dextrose broth medium (purchased from Aladdin Company), add 1000mL of water, sterilize in an autoclave at 121°C for 30min, take it out and cool and inoculate with Mucor racemosus XH-22 (provided by Shaoxing Xianheng Food Factory) , No. AS3.25), Aspergillus oryzae (provided by Shaoxing Xianheng Food Factory, No. AS3.800), Bacillus subtilis (ATCC 23857) (ratio 60:20:20), expanded culture in constant temperature and humidity box, culture temperature The temperature is 25°C and the time is 48h. After the cultivation, the culture product was taken out and fi...

Embodiment 2

[0078] (1) Pretreatment of pigskin:

[0079] Get fresh pigskin, wash it with water, scrape off excess fat and pig hair with a knife, cut it into small pieces of 3cm*3cm, wash it with water, and then sterilize it with 3% (w / w) food-grade hydrogen peroxide for 3 hours , washed repeatedly with clear water to obtain sterilized pigskin for later use.

[0080] (2) Preparation of inoculation solution A

[0081] Take 37.5g of potato dextrose broth medium (purchased from Aladdin Company), add 1000mL of water, sterilize in an autoclave at 121°C for 30min, take it out and cool and inoculate with Mucor racemosus XH-22 (provided by Shaoxing Xianheng Food Factory) , No. AS3.25), Aspergillus oryzae (supplied by Shaoxing Xianheng Food Factory, No. AS3.800), Bacillus subtilis (ATCC 23857) at a ratio of 50:25:25, and expanded culture in a constant temperature and humidity box at a temperature of 25 ℃, the time is 48h. The culture product was taken out and filtered, and the obtained filtrate ...

Embodiment 3

[0096] (1) Pretreatment of pigskin:

[0097] Get fresh pigskin, wash it with water, scrape off excess fat and pig hair with a knife, cut it into small pieces of 3cm*3cm, wash it with water, and then sterilize it with 3% (w / w) food-grade hydrogen peroxide for 3 hours , washed repeatedly with clear water to obtain sterilized pigskin for later use.

[0098] (2) Preparation of inoculation solution A

[0099] Take 37.5g of potato dextrose broth medium (purchased from Aladdin Company), add 1000mL of water, sterilize in an autoclave at 121°C for 30min, take it out and cool and inoculate with Mucor racemosus XH-22 (provided by Shaoxing Xianheng Food Factory) , No. AS3.25), Aspergillus oryzae (supplied by Shaoxing Xianheng Food Factory, No. AS3.800), Bacillus subtilis (ATCC 23857) at a ratio of 40:30:30, and expanded culture in a constant temperature and humidity box at a temperature of 25 ℃, the time is 48h. The culture product was taken out and filtered, and the obtained filtrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com