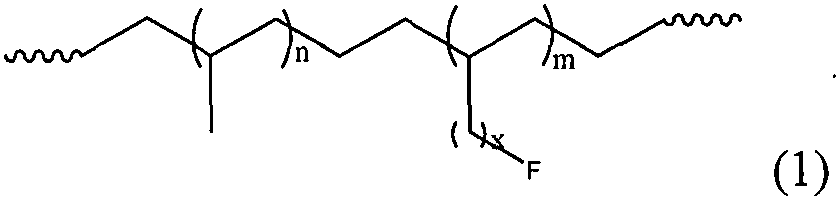

Preparation method of functionalized polypropylene copolymer

A polypropylene copolymer, functionalized technology, applied in the field of preparation of functionalized polypropylene copolymer, to achieve the effects of enhancing printing and dyeing properties, expanding application fields, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

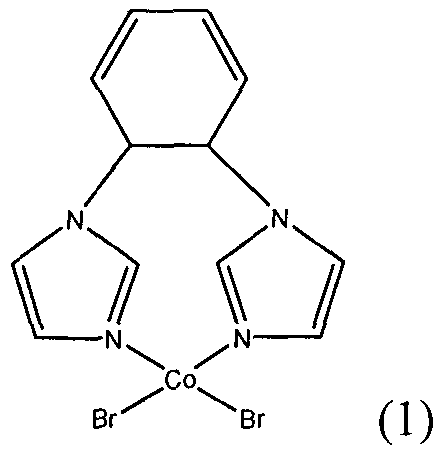

Embodiment 1

[0017] Add o-dichlorobenzene (0.1 mol) in methanol (20 mL) dropwise with imidazole (0.25 mol) in absolute ethanol (40 mL). A few drops of 5% sodium hydroxide in ethanol were added to the reaction mixture. Reflux at 80°C for 8 hours and then allow overnight. The sodium chloride was filtered, the filtrate was evaporated and recrystallized from ethanol, the yield of 1,2-diimidazobenzene was 89%.

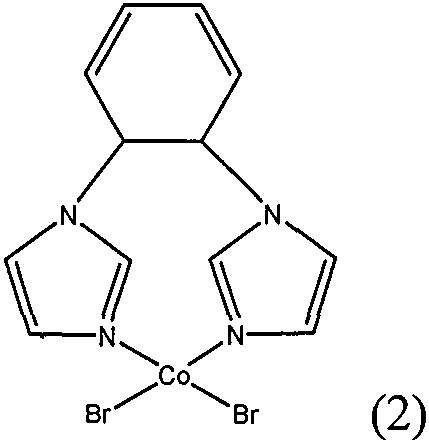

Embodiment 2

[0019] Take a 100ml reactor, add 50ml tetrahydrofuran, add 190mg 1,2-diimidazolium benzene, add 305mg NiBr2 (DME), stir for 12 hours, spin off the solvent, and obtain a light yellow powder as 1,2-diimidazolium cobalt bromide, Yield 97%.

Embodiment 3

[0021] A dry 250ml autoclave with a magnetic stirring bar was replaced three times with nitrogen and twice with propylene. Heat the oil bath to 50°C, add 100ml of toluene, 1mL of 7-octen-1 alcohol, 4ml of MAO, start stirring, add 1.2mmol of 1,2-diimidazolium benzene cobalt bromide catalyst with a syringe, and control the propylene pressure of the system with a solenoid valve Keep 1.03×10 6 Pa, start to carry out propylene copolymerization. After 30 minutes, the propylene valve was closed, treated with acid alcohol, and filtered to obtain 9.8 g of copolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com