KH-560/nano ZnO composite antibacterial film with starch substrate and preparation method of KH-560/nano ZnO composite antibacterial film with starch substrate

A KH-560, composite antibacterial technology, applied in the field of natural polymer antibacterial film, can solve the problems of reduced mechanical stability of composite antibacterial materials, affecting antibacterial performance of composite antibacterial materials, low nano-ZnO content, etc. and ecological problems, increase the content, improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

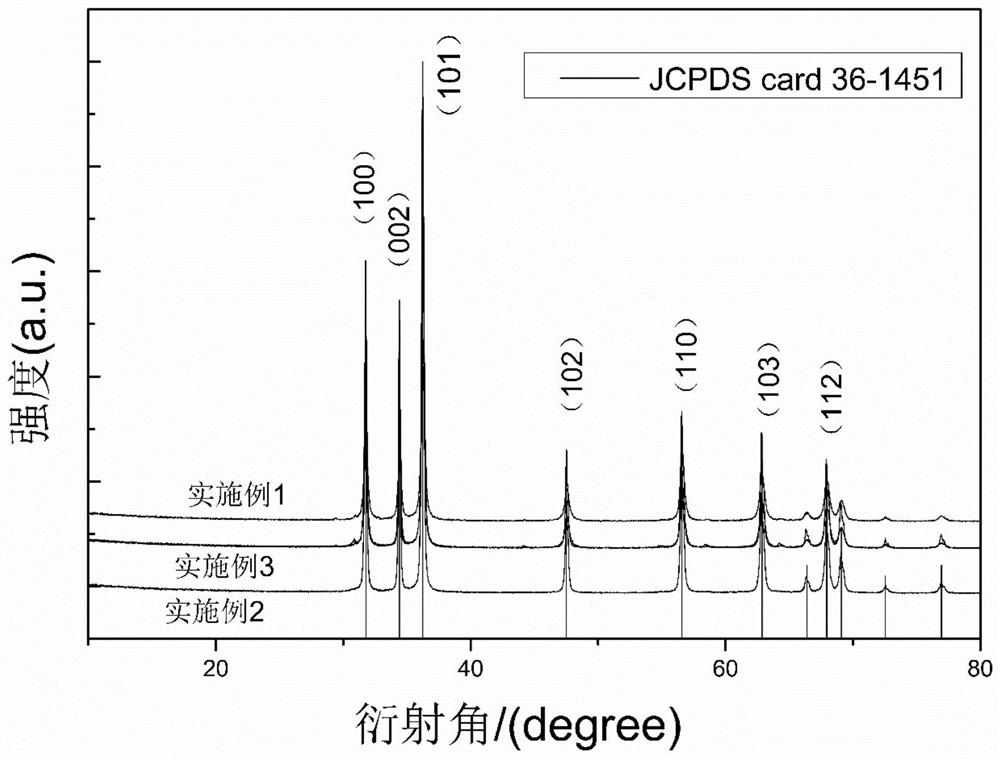

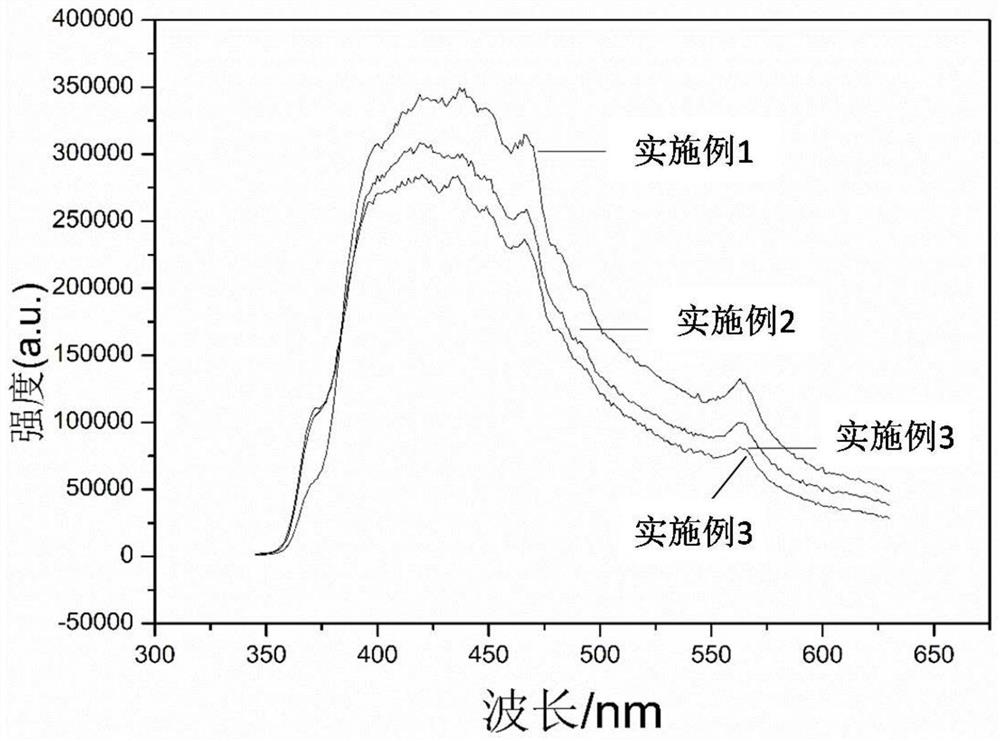

Embodiment 1

[0036] This embodiment provides a method for preparing the starch-based KH-560 / nano-ZnO flexible antibacterial film, comprising the following steps:

[0037] (1) Preparation of nano-ZnO:

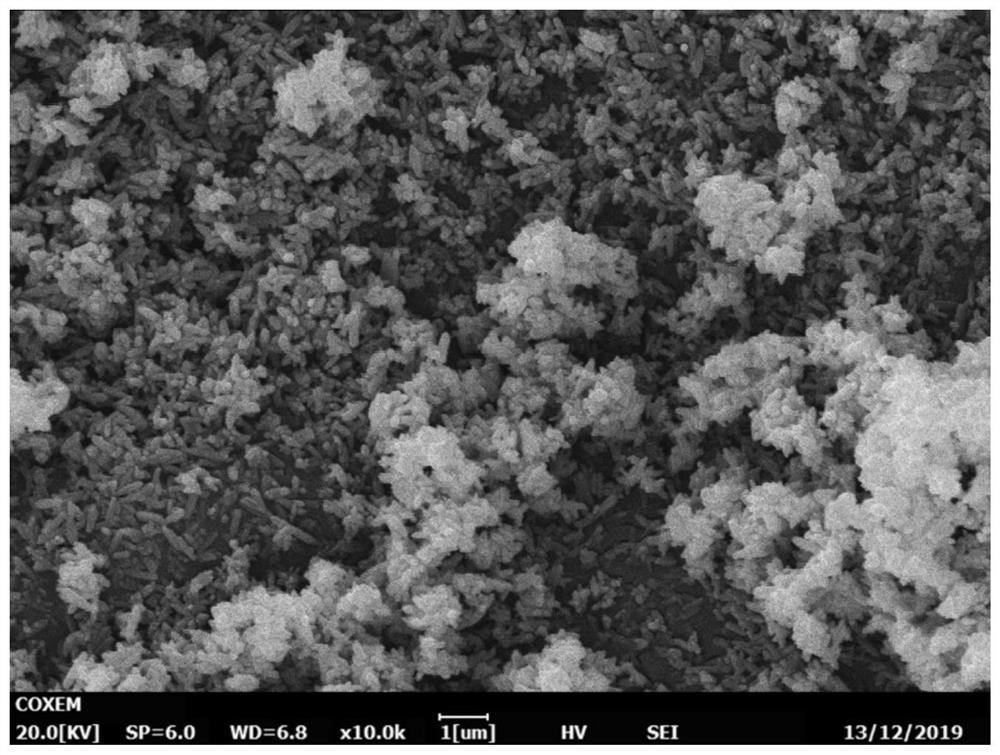

[0038] Take 5.4 g of zinc nitrate hexahydrate, dissolve it in 120 mL of deionized water, place it under an electric stirrer, add 2 moL / L sodium hydroxide solution dropwise while stirring, adjust the pH to 10.8, continue stirring for 0.5 h, and transfer the liquid to In a polytetrafluoroethylene reactor, react at 120°C for 10h. After the polytetrafluoroethylene reactor was cooled, the white precipitate formed by the reaction was alternately washed with deionized water and absolute ethanol, centrifuged three times, and dried in vacuum at 75° C. for 14 hours to obtain white nano-ZnO.

[0039](2) Preparation of KH-560 / nano-ZnO: Take 1g of dry nano-ZnO, add it into a four-necked flask filled with 200g of water-absolute ethanol (m water:m absolute ethanol=1:4), and ultrasonicate at 100W for 60min...

Embodiment 2

[0042] This embodiment provides a method for preparing the starch-based KH-560 / nano-ZnO flexible antibacterial film, comprising the following steps:

[0043] (1) Preparation of nano-ZnO:

[0044] Take 1.8 g of zinc nitrate hexahydrate, dissolve it in 120 mL of deionized water, place it under an electric stirrer, add 2 moL / L sodium hydroxide solution dropwise while stirring, adjust the pH to 8.5, continue stirring for 0.5 h, and transfer the liquid to In a polytetrafluoroethylene reactor, react at 120°C for 20h. After the polytetrafluoroethylene reactor was cooled, the white precipitate formed by the reaction was alternately washed with deionized water and absolute ethanol, centrifuged three times, and dried in vacuum at 40° C. for 24 hours to obtain white nano-ZnO.

[0045] (2) Preparation of KH-560 / nano-ZnO: Take 1g of dried nano-ZnO, add it into a four-necked flask filled with 200g of water-absolute ethanol (m water:m absolute ethanol=1:9), and ultrasonicate at 300W for 20m...

Embodiment 3

[0048] This embodiment provides a method for preparing the starch-based KH-560 / nano-ZnO flexible antibacterial film, comprising the following steps:

[0049] (1) Preparation of nano-ZnO:

[0050] Take 7.2g of zinc nitrate hexahydrate, dissolve it in 120mL of deionized water, place it under an electric stirrer, add 2moL / L sodium hydroxide solution dropwise while stirring, adjust the pH to 13, continue stirring for 0.5h, and transfer the liquid to In a polytetrafluoroethylene reactor, react at 120°C for 15h. After the polytetrafluoroethylene reactor was cooled, the white precipitate formed by the reaction was alternately washed with deionized water and absolute ethanol, centrifuged three times, and vacuum-dried at 60° C. for 18 hours to obtain white nano-ZnO.

[0051] (2) Preparation of KH-560 / nano-ZnO: Take 1g of dry nano-ZnO, add it into a four-necked flask filled with 200g of water-absolute ethanol (m water: m absolute ethanol = 1:19), and ultrasonicate at 200W for 45min. R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com