Zn-containing medium-strength high-ductility die-cast aluminum alloy and preparation method thereof

A technology for casting aluminum alloy and casting aluminum alloy, applied in the field of metal materials, can solve problems such as being unsuitable for die-casting, restricting alloy plasticity, etc., and achieve the effects of low cost, improving alloy plasticity, and promoting transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

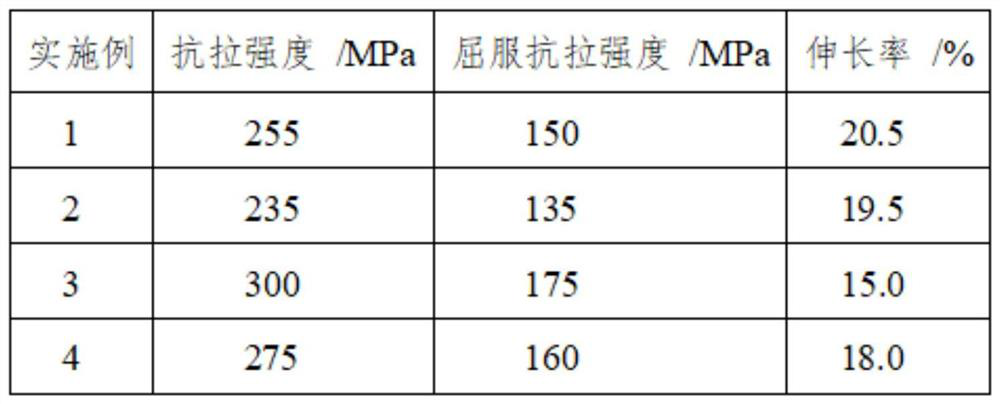

Examples

Embodiment 1

[0022] The design composition is: Al-10% Si-5.5% Zn-0.6% Fe-0.3% Mn-0.02% Sr; that is, 10% Si, 5.5% Zn, 0.6% Fe, 0.3% Mn, 0.02% Sr and the balance are composed of Al.

[0023] (1) Proportionate ingredients, 85% of the aluminum ingots by mass fraction, all Si ingots, Fe agent, Mn agent, etc. are put into the smelting furnace, and the temperature is raised to 780 ° C;

[0024] (2) After the raw materials in the furnace are completely melted, add the remaining aluminum ingots and Zn ingots, and stir the melt, while the temperature in the furnace drops to 700°C;

[0025] (3) Sampling and testing the alloy composition in the middle of the melt, comparing the design composition with the measured composition, and adjusting the alloy composition to the design range;

[0026] (4) Press the aluminum foil-wrapped and preheated Al-Sr master alloy into the melt with a titanium tool, and slowly stir the melt;

[0027] (5) Spray the refining agent into the melt with high-purity nitrogen as...

Embodiment 2

[0029] The design composition is: Al-12% Si-4.1% Zn-0.8% Fe-0.15% Mn-0.03% Sr, that is, 12% Si, 4.1% Zn, 0.8% Fe, 0.15% Mn, 0.03% Sr and the balance are composed of Al.

[0030] (1) Dosing in proportion, 90% of the aluminum ingot by mass fraction, all Si ingots, Fe agent, Mn agent, etc. are put into the smelting furnace, and the temperature is raised to 800 ° C;

[0031] (2) After the raw materials in the furnace are completely melted, add the remaining aluminum ingots and Zn ingots, and stir the melt, while the temperature in the furnace drops to 720°C;

[0032] (3) Sampling and testing the alloy composition in the middle of the melt, comparing the design composition with the measured composition, and adjusting the alloy composition to the design range;

[0033] (4) Press the aluminum foil-wrapped and preheated Al-Sr master alloy into the melt with a titanium tool, and slowly stir the melt;

[0034] (5) Spray the refining agent into the melt with high-purity nitrogen as a c...

Embodiment 3

[0036] The design composition is: Al-11% Si-7.0% Zn-0.5% Fe-0.4% Mn-0.02% Sr, that is, 11% Si, 7.0% Zn, 0.5% Fe, 0.4% Mn, 0.02% Sr and the balance are composed of Al.

[0037] (1) Proportionate batching, wherein 70% of the mass fraction of aluminum ingots, all Si ingots, Fe agent, Mn agent, etc. are put into the smelting furnace, and the temperature is raised to 760 ° C;

[0038] (2) After the raw materials in the furnace are completely melted, add the remaining aluminum ingots and Zn ingots, and stir the melt, while the temperature in the furnace drops to 710°C;

[0039] (3) Sampling and testing the alloy composition in the middle of the melt, comparing the design composition with the measured composition, and adjusting the alloy composition to the design range;

[0040] (4) Press the aluminum foil-wrapped and preheated Al-Sr master alloy into the melt with a titanium tool, and slowly stir the melt;

[0041] (5) Spray the refining agent into the melt with high-purity nitrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com