Preparation method of AuCu bimetallic electrocatalyst with pentagram structure

An electrocatalyst and alloy catalyst technology, applied in structural parts, circuits, electrical components, etc., can solve the problems of reduced energy efficiency, hydrogen evolution side reactions, catalyst deactivation, etc., and achieve reduced reduction potential, high reaction efficiency, and simple synthesis method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

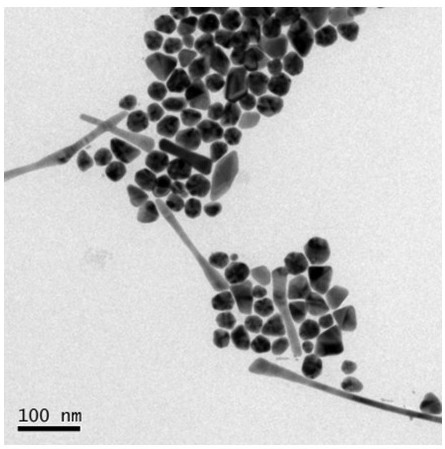

[0021] Dissolve 0.5g of hexadecylamine and 0.9g of glucose in 80mL of distilled water, stir vigorously overnight, add 0.3g of tetrachloroauric acid hydrate and 0.03g of copper chloride, mix well, and react in an oil bath at 100°C for 30 minutes to obtain black Red, uniform and stable solution, after washing several times with absolute ethanol to obtain Au 3 Cu 1 Nano-particles, ultrasonically dispersed in an ethanol solution to obtain a standby solution; add a certain quality of XC-72 carbon black to the standby solution, stir and disperse, and then stand at room temperature. After the supernatant is clear, the supernatant is sucked out The black precipitate deposited to the bottom was dried in a vacuum drying oven at 45°C to obtain an AuCu alloy catalyst supported on carbon black. by figure 1 It can be seen that the Au prepared in this example 3 Cu 1 The diameter of the nanoparticles is between 35-40 nm.

[0022] Take 2 mg of the AuCu alloy catalyst loaded on carbon black prepar...

Embodiment 2

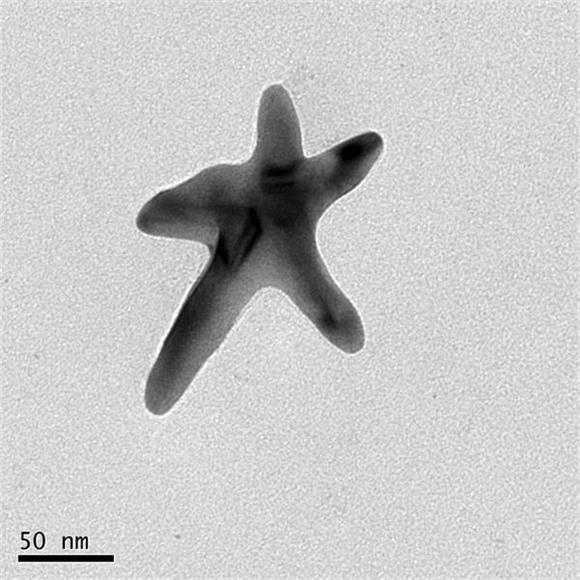

[0024] Dissolve 0.5g of hexadecylamine and 0.9g of glucose in 80mL of distilled water, stir vigorously overnight, add 0.2g of tetrachloroauric acid hydrate and 0.07g of copper chloride, mix well and react in an oil bath at 100℃ for 30 minutes to obtain black Red, uniform and stable solution, after washing several times with absolute ethanol to obtain Au 1 Cu 1 Five-pointed star nanoparticles are ultrasonically dispersed in an ethanol solution to obtain a standby solution; add a certain quality of XC-72 carbon black to the standby solution, stir and disperse, and then stand at room temperature. After the supernatant is clarified, suck up The clear liquid, and the black precipitate that settled to the bottom was dried in a vacuum drying oven at 45°C to obtain an AuCu alloy catalyst supported on carbon black. by figure 1 It can be seen that the Au prepared in this example 1 Cu 1 The pentagonal diameter is between 17-23nm.

[0025] Take 2 mg of the AuCu alloy catalyst loaded on carbo...

Embodiment 3

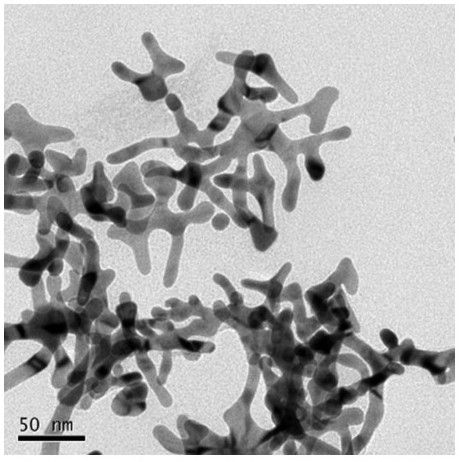

[0027] Dissolve 0.5g of hexadecylamine and 0.9g of glucose in 80mL of distilled water, stir vigorously overnight, add 0.08g of tetrachloroauric acid hydrate and 0.1g of copper chloride, mix well, and react in an oil bath at 100°C for 30 minutes to obtain black Red, uniform and stable solution, after washing several times with absolute ethanol to obtain Au 1 Cu 3 Nano-branches are ultrasonically dispersed in ethanol solution to obtain a standby solution; add a certain quality of XC-72 carbon black to the standby solution, stir and disperse, and then stand at room temperature. After the supernatant is clear, the supernatant is sucked out The black precipitate deposited to the bottom was dried in a vacuum drying cabinet at 45°C to obtain an AuCu alloy catalyst supported on carbon black. by figure 1 It can be seen that the Au prepared in this example 1 Cu 3 The diameter of the nanobranches is between 7-16 nm.

[0028] Take 2 mg of the AuCu alloy catalyst loaded on carbon black prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com