Iron-based active reaction type deoxidizer with high oxidation rate and water locking function and preparation method thereof

A technology of oxidation rate and reaction type, applied in the field of deoxidizers, can solve the problems of reducing the effective content of iron, accelerating water evaporation, affecting the stability of gram weight, etc., and achieves the effect of preventing content reduction, inhibiting mildew, and increasing equipment load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

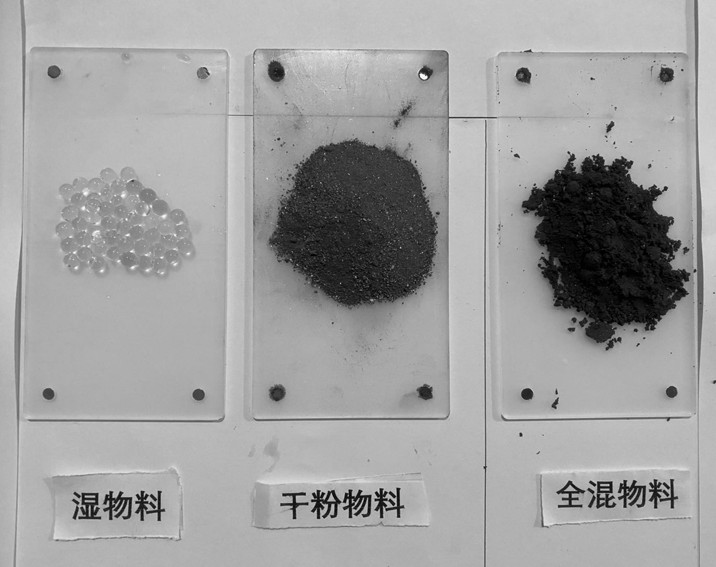

[0034] Step 1: Soak water-absorbing beads (hydrophilic superabsorbent resin) with a particle size of 2.5~3mm in a saturated saline solution, take it out after 12 hours, and let it stand for 1 hour to dry the salt solution on the surface to obtain wet materials.

[0035] Step 2: Weigh 73 parts (36.5 kg) of 200-mesh spongy reduced iron powder and 2 parts (1 kg) of ultra-high conductive flake graphite, and mix and grind them for 2 hours.

[0036] Step 3: Weigh 2 parts of anhydrous sodium chloride (1kg), 3.5 parts of anhydrous sodium sulfite (1.75kg), 0.2 parts of golden vermiculite (0.1kg), 0.2 parts of volcanic rock (0.1kg), anhydrous silica 0.2 parts (0.1 kg) were mixed with the materials in step 2 and stirred for 1 hour.

[0037] Step 4: Pack 10 parts (5kg) of the wet material in step 1 and 81.1 parts (40.55kg) of the dry powder material in step 3 through a double-tray or multi-tray packaging machine to obtain an iron system with a high oxidation rate and water-locking functio...

Embodiment 2

[0039] Step 1: Soak water-absorbing beads (hydrophilic superabsorbent resin) with a particle size of 2.5~3mm in a saturated saline solution, take it out after 12 hours, and let it stand for 1 hour to dry the salt solution on the surface to obtain wet materials.

[0040] Step 2: Weigh 65 parts (32.5kg) of 150-mesh cast iron powder and 3 parts (1.5kg) of ultra-high conductive flake graphite, and mix and grind them for 2 hours.

[0041] Step 3: Weigh 4 parts of anhydrous sodium chloride (2kg), 4 parts of anhydrous sodium sulfite (2kg), 0.1 part of golden vermiculite (0.05kg), 0.3 parts of volcanic rock (0.15kg), and 0.4 parts of anhydrous silicon dioxide Part (0.2kg) was mixed with the material in step 2 and stirred for 1 hour.

[0042] Step 4: Pack 12 parts (6kg) of the wet material in step 1 and 76.8 parts (38.4kg) of the dry powder material in step 3 through a double-tray or multi-tray packaging machine to obtain an iron system with a high oxidation rate and water-locking func...

Embodiment 3

[0044] Step 1: Soak a cellulose acetate stick with a diameter of 0.5 cm and a length of 1.5 cm in a saturated saline solution, take it out after 12 hours, let it stand for 30 minutes, and control the salt solution on the surface to dry up to obtain a wet material.

[0045] Step 2: Weigh 60 parts (30kg) of 100-mesh cast iron powder and 3 parts (1.5kg) of ultra-high conductive flake graphite, and mix and grind them for 2 hours.

[0046] Step 3: Weigh 5 parts of anhydrous sodium chloride (2.5kg), 3 parts of anhydrous sodium metabisulfite (1.5kg), 2 parts of quicklime (1kg), 0.1 part of volcanic rock (0.05kg), and 0.4 parts of anhydrous silicon dioxide Part (0.2kg) was mixed with the material in step 2 and stirred for 1 hour.

[0047] Step 4: Pack 11 parts (5.5kg) of the wet material in step 1 and 73.7 parts (36.85kg) of the dry powder material in step 3 through a double-tray or multi-tray packaging machine to obtain iron with high oxidation rate and water-locking function. Depar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com