Size-controllable sodium alginate/polylysine self-assembled fiber

A technology of polylysine and sodium alginate, which is applied in fiber processing, fiber chemical characteristics, filament/thread forming, etc., can solve the problems that cannot meet the requirements of industrialization, poor mechanical properties of materials, and expensive equipment and equipment, and achieve Satisfy the effects of large-scale industrial production, high production efficiency, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing a size-controllable sodium alginate / polylysine self-assembled fiber, comprising the steps of:

[0046] (1) Prepare sodium alginate solution:

[0047] Weigh a certain amount of sodium alginate and add it into water, stir well until the sodium alginate is completely dissolved, prepare a 1wt% sodium alginate solution, perform ultrasonic treatment to remove air bubbles, and set aside;

[0048] (2) Preparation of polylysine solution: Weigh a certain amount of polylysine and add it to deionized water, stir and dissolve to prepare a 2wt% polylysine solution for later use;

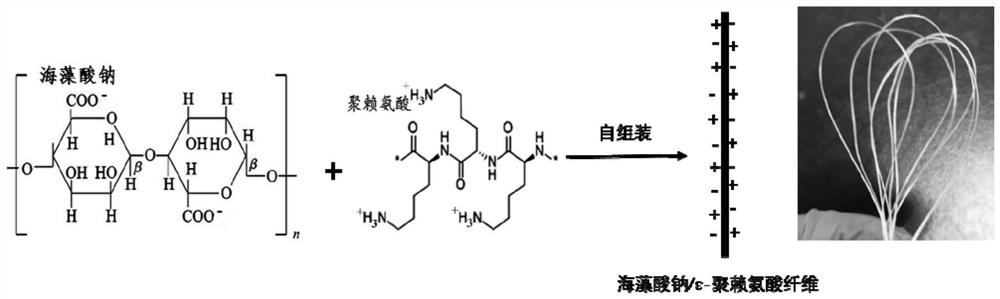

[0049] (3) Mixing of sodium alginate / polylysine: add the 1wt% sodium alginate and 2wt% polylysine solution prepared above into a beaker with an inner diameter of 35.1 mm at a ratio of 3:1, and mix them within 0.5 minutes. A self-assembled polymer film is formed at the interface of the two solutions;

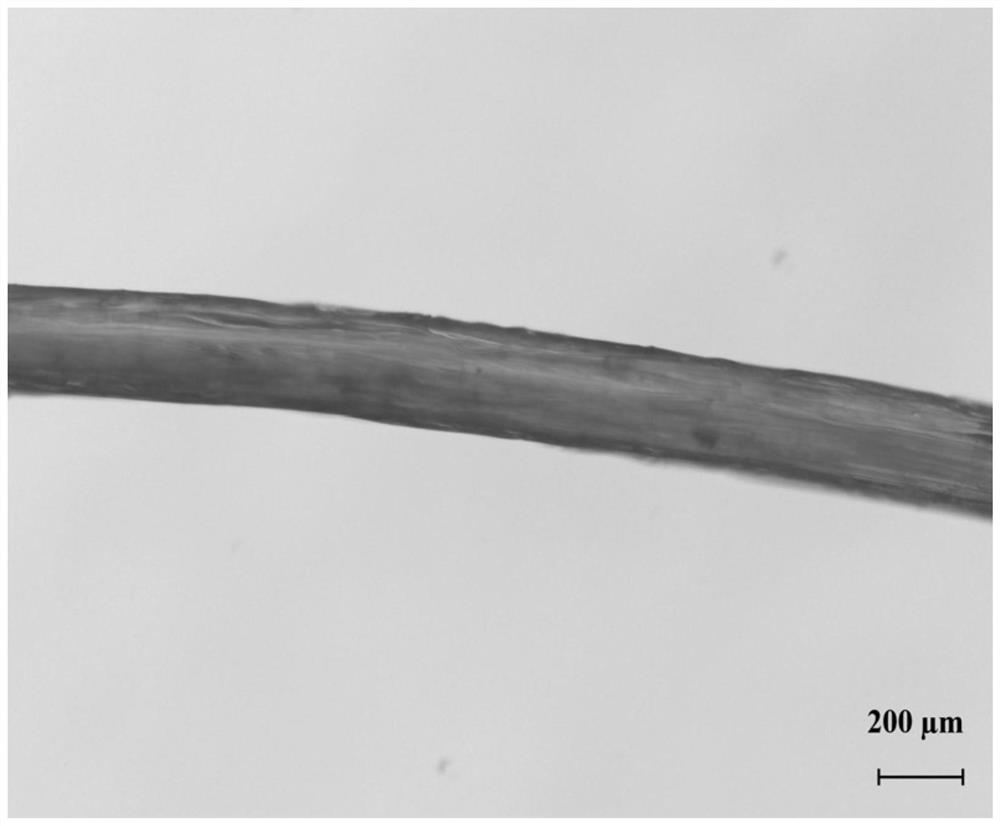

[0050] (4) Preparation of fibers: the above-mentioned self-assembled polymer film wa...

Embodiment 2

[0053] A kind of preparation method of sodium alginate / polylysine self-assembled fiber with controllable size, such as figure 1 shown, including the following steps:

[0054] (1) Preparation of sodium alginate solution: Weigh a certain amount of sodium alginate and add it to water, fully stir until the sodium alginate is completely dissolved, prepare a 2wt% sodium alginate solution, perform ultrasonic treatment to remove air bubbles, and set aside;

[0055] (2) Preparation of polylysine solution: Weigh a certain amount of polylysine into water, stir and dissolve to prepare 1wt% polylysine solution, and set aside;

[0056] (3) Sodium alginate / polylysine mixing: add the above-mentioned 2wt% sodium alginate and 1wt% polylysine solution into a beaker with an inner diameter of 15.6 mm at a ratio of 1:5, and within 10 seconds A self-assembled polymer film is formed at the interface of the two solutions;

[0057] (4) Preparation of fibers: the above-mentioned self-assembled polymer...

Embodiment 3

[0062] A method for preparing a size-controllable sodium alginate / polylysine self-assembled fiber, comprising the steps of:

[0063] (1) Preparation of sodium alginate solution: Weigh a certain amount of sodium alginate and add it to water, fully stir until the sodium alginate is completely dissolved, prepare a 2wt% sodium alginate solution, perform ultrasonic treatment to remove air bubbles, and set aside;

[0064] (2) Preparation of polylysine solution: Weigh a certain amount of polylysine and add it to water, stir and dissolve to prepare a 5wt% polylysine solution for subsequent use;

[0065] (3) Mixing of sodium alginate / polylysine: add the 2wt% sodium alginate and 5wt% polylysine solution prepared above into a beaker with an inner diameter of 6.2 mm at a ratio of 5:1, and dissolve the two mixtures within 0.5 minutes. A self-assembled polymer film is formed at the interface of the two solutions;

[0066] (4) Preparation of fibers: the above-mentioned self-assembled polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com