Resistance furnace for silicon carbide micro powder production and using method thereof

A silicon carbide powder, resistance furnace technology, applied in the direction of silicon carbide, carbide, furnace, etc., can solve the problems of environmental pollution, generation of harmful gas, poor use effect of resistance furnace, etc., to avoid damage, purify emissions, The effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

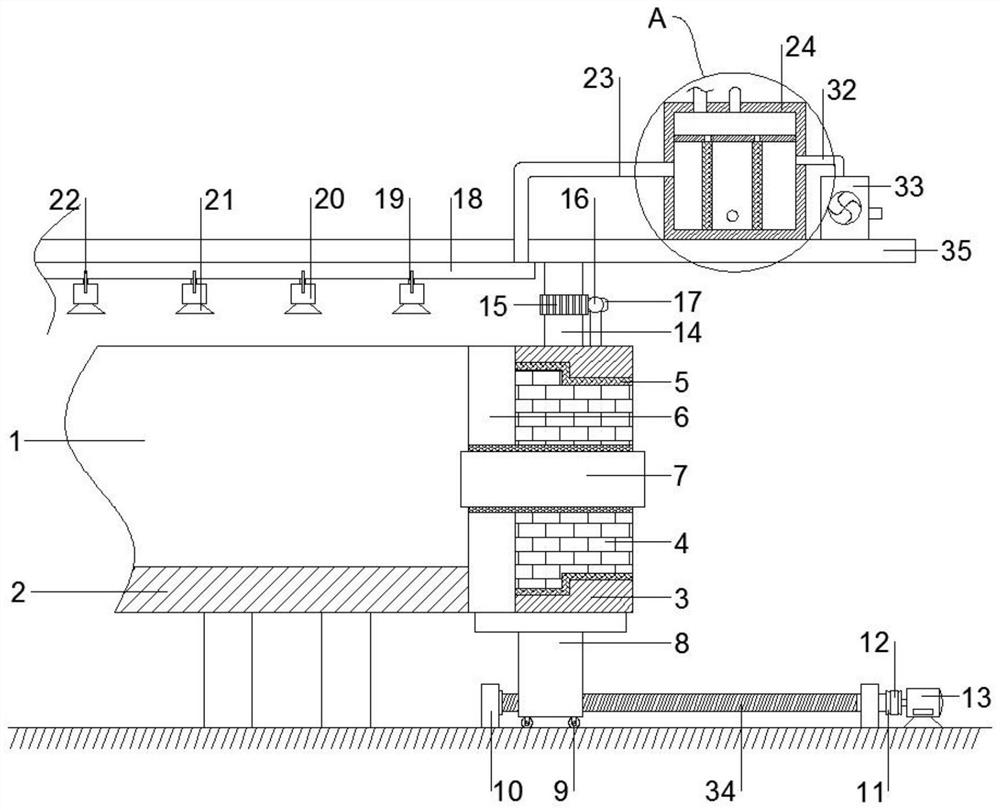

[0034] see Figure 1-5 , the present invention provides a technical solution: a resistance furnace for silicon carbide powder production, comprising a furnace wall plate 1 and a furnace bottom support 2, the furnace wall plate 1 is located on the upper side of the furnace bottom support 2, and the right end of the furnace wall plate 1 A reinforced concrete frame 3 is detachably installed, and a refractory brick layer 4 is installed on the inner wall of the reinforced concrete frame 3, and a thermal insulation layer 6 is fixed on the outer wall of the reinforced concrete frame 3 and the refractory brick layer 4, and the thermal insulation 6 is closely attached to the furnace wall plate 1, the right end of the furnace wall plate 1 is provided with an electrode 7, the electrode 7 penetrates the heat insulation layer 6 and the refractory brick layer 4, and the outer wall of the electrode 7 is fixed with a sealing protection ring, and the reinforced concrete frame 3 The bottom end ...

Embodiment 2

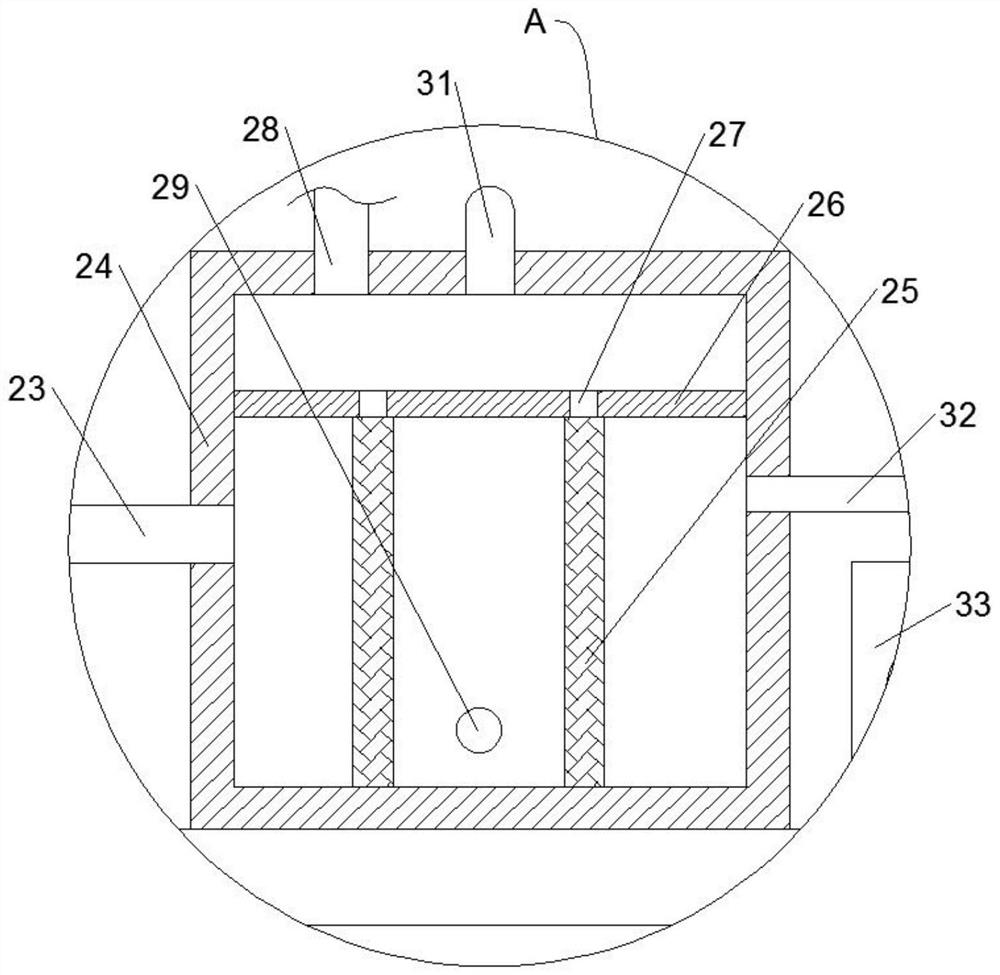

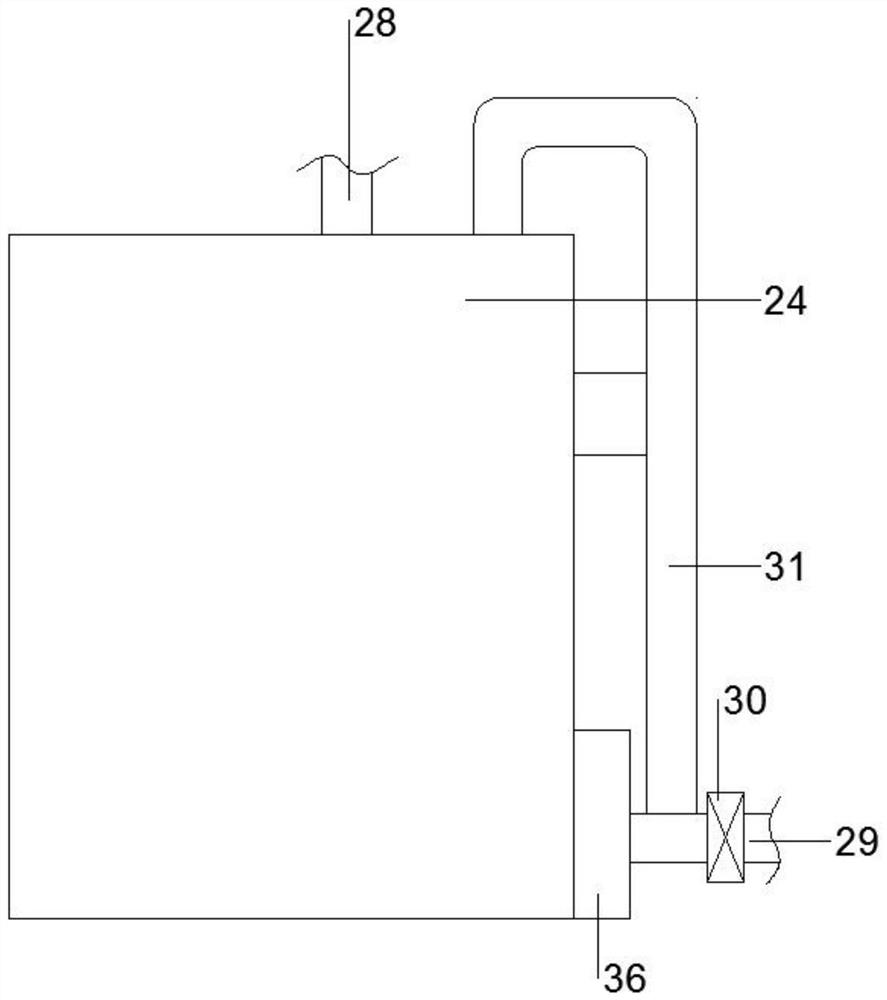

[0042] On the basis of Embodiment 1, the top of the reinforced concrete frame 3 is rotatably connected with a rotating column 14, and the rotating column 14 is correspondingly connected with a second motor 17, and the top of the rotating column 14 is fixed with a support plate 35, and the bottom end of the support plate 35 The position corresponding to the left side of the rotating column 14 is fixed with a shunt pipe 18, and the bottom end of the shunt pipe 18 is connected with a plurality of suction pipes 20 through the connecting pipe 19. The suction pipe 20 is fixed with the support plate 35 by the fixed rod 22, and the suction The bottom end of the pipe 20 is evenly connected with a plurality of suction hoods 21, and the top of the support plate 35 is fixed with a purification box 24 corresponding to the right side of the rotating column 14. The left end of the purification box 24 is connected with an air intake pipe 23, and the air intake pipe 23 is far away from the purif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com