Silicon dioxide microsphere surface loaded ferrous sulfide nanocrystal, and preparation method and application thereof

A technology of silicon dioxide and ferrous sulfide, which is applied in the field of nanomaterials, can solve the problems of insufficient performance improvement, complex raw materials, and cumbersome steps of amorphous structure sulfurized nano-zero-valent iron, and achieve good application prospects, high reactivity, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

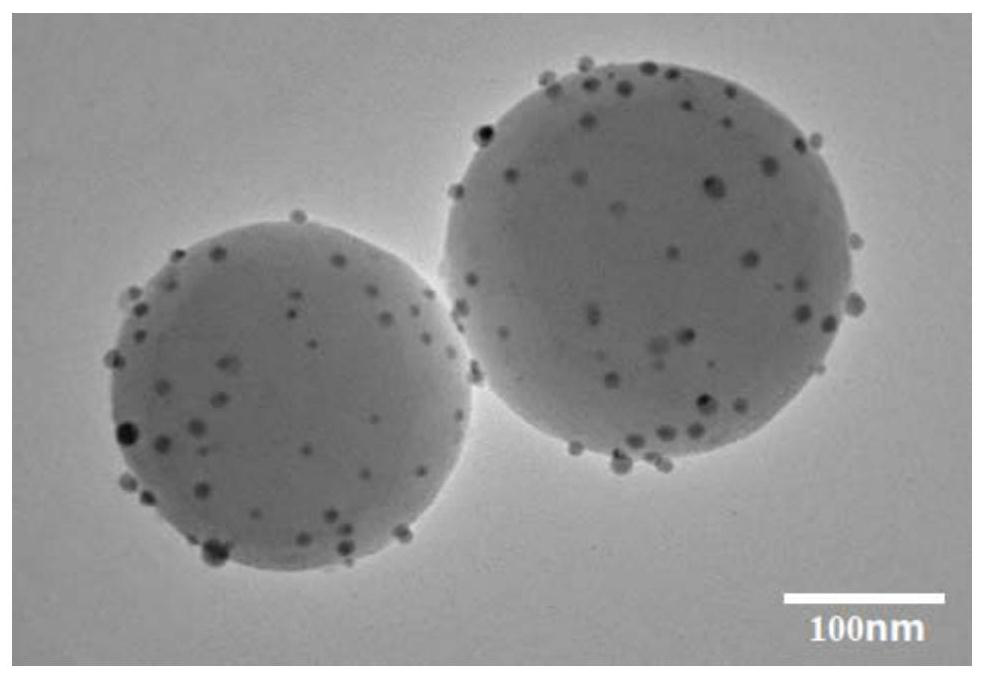

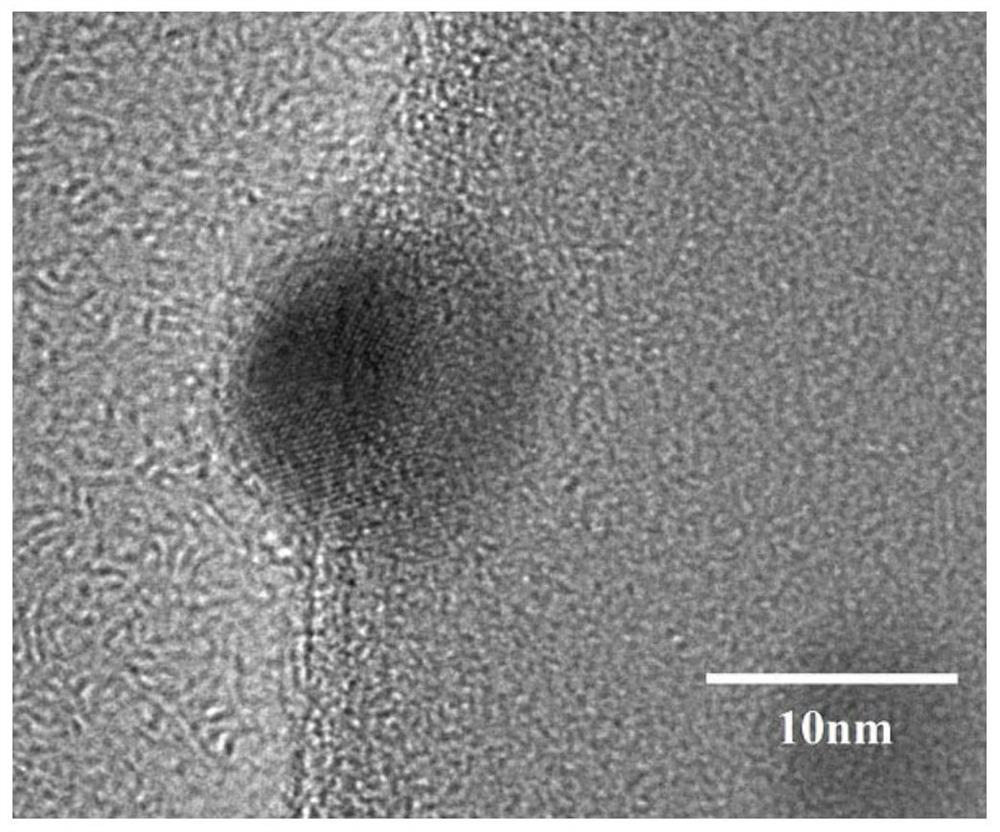

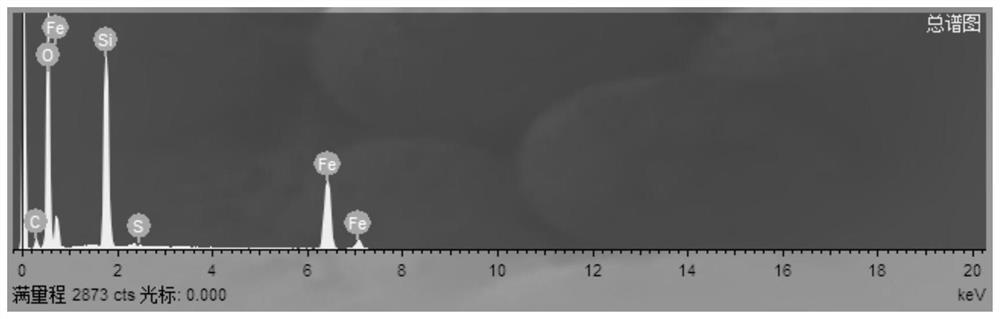

[0038] In the second aspect, the present invention provides a method for preparing a ferrous sulfide nanocrystalline composite material supported on the surface of silica microspheres. The preparation method comprises: (1) preparing solid silica microspheres; (2) modifying the surface of the solid silica microspheres with mercapto groups to obtain mercapto-modified silica microspheres; (3) preparing silica microspheres modified with mercapto groups; Ferrous sulfide crystals loaded on the surface of silica microspheres.

[0039] In one embodiment, the preparation method of the silicon dioxide microsphere surface loading ferrous sulfide nanocrystalline composite material of the present invention comprises:

[0040] (1) Prepare silica solid microspheres under the condition of no template

[0041] Mix 5 to 20 parts by volume of absolute ethanol, 3 to 10 parts by volume of deionized water and 0.5 to 2 parts by volume of ammonia water, stir in a constant temperature water bath at 2...

Embodiment 1

[0064] (1) Mix 50mL of absolute ethanol, 15mL of deionized water and 5mL of ammonia water, and stir in a constant temperature water bath at 35°C for 10min to mix all components evenly; Continue to stir at a constant speed in the constant temperature water bath, add 0.5mL 3-(mercaptopropyl)triethoxysilane to the system after 12 hours of reaction, and ultrasonically disperse the surface mercapto-modified silica solid microspheres after continuing the reaction for 12 hours.

[0065] (2) Under the condition of nitrogen protection, disperse the product obtained in step (1) into 60mL water, then mix with 5mL of 15mmol / L ferrous sulfate solution, and drop 5mmol / L of ferrous sulfate solution at a speed of 2mL / min Thioacetamide solution 4.2mL, reacted at 35°C for 2h.

[0066] (3) Centrifuge the obtained dispersion at room temperature at 10,000 r / min for 5 minutes, wash the separated solid with water twice, and dry it in a constant temperature drying oven at 50°C to obtain the vulcanize...

Embodiment 2

[0073] (1) Mix 70mL of absolute ethanol, 25mL of deionized water and 5mL of ammonia water, and stir in a constant temperature water bath at 25°C for 10min to mix all components evenly; Continue stirring at a constant speed in a constant temperature water bath, add 1mL of 3-(mercaptopropyl)triethoxysilane to the system after reacting for 24 hours, and ultrasonically disperse the surface mercapto-modified silica solid microspheres after continuing the reaction for 24 hours.

[0074] (2) Under the condition of nitrogen protection, disperse the product obtained in step (1) into 60mL water, then mix with 5mL of 10mmol / L ferrous sulfate solution, and add 10mmol / L of Thioacetamide solution 3.3mL, reacted at 55°C for 0.5h.

[0075] (3) Centrifuge the obtained dispersion at room temperature at 10,000 r / min for 5 minutes, wash the separated solid with water twice, and dry it in a constant temperature drying oven at 50°C to obtain the vulcanized silica microspheres supported on the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com