Inorganic modified starch fluid loss reducer for drilling fluid and preparation method thereof

A filtrate reducer and inorganic modification technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of environmental protection performance advantage decline, biodegradability, drilling fluid viscosity increase, etc., to meet production requirements Environmental protection requirements, improved thermal stability, and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

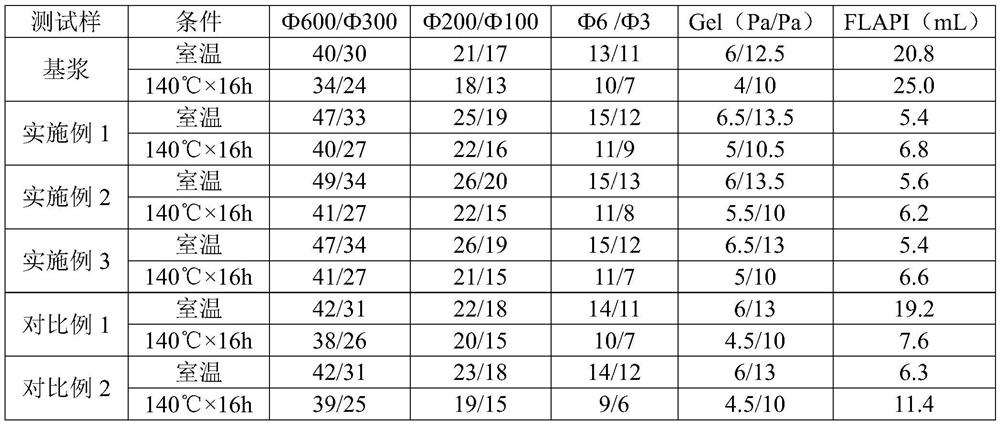

Examples

Embodiment 1

[0024] A preparation method of inorganic modified starch fluid loss reducer for drilling fluid, the steps are as follows:

[0025] S1. Dispersing 100 parts by weight of cornstarch into 200 parts by weight of deionized water to obtain a starch suspension, adding sodium hydroxide to adjust the pH of the starch suspension to 7;

[0026] S2. Warm up the starch suspension to 40°C, add 1.5 parts by weight of sodium trimetaphosphate, and react at 40°C for 4 hours while stirring;

[0027] S3. Continue to add 3 parts by weight of acetic anhydride to the reaction solution obtained in step S2, and continue to react at 40° C. for 4 hours while stirring; and add sodium hydroxide after the reaction to adjust the pH of the reaction solution to 7;

[0028] S4, rotary evaporation removes the solvent in the reaction product liquid, and the obtained solid product is dried and pulverized;

[0029] S5, add the deionized water that weight is 3% of solid particle weight to the solid particle obtain...

Embodiment 2

[0031] A preparation method of inorganic modified starch fluid loss reducer for drilling fluid, the steps are as follows:

[0032] S1. Dispersing 100 parts by weight of cornstarch into 200 parts by weight of deionized water to obtain a starch suspension, adding sodium hydroxide to adjust the pH of the starch suspension to 7;

[0033] S2. Warming the starch suspension to 40°C, adding 2 parts by weight of sodium trimetaphosphate, and reacting at 40°C for 4 hours while stirring;

[0034] S3. Continue to add 5 parts by weight of acetic anhydride to the reaction solution obtained in step S2, and continue to react at 40° C. for 4 hours under stirring; and add sodium hydroxide after the reaction to adjust the pH of the reaction product to 7;

[0035] S4, rotary evaporation removes the solvent in the reaction product liquid, and the obtained solid product is dried and pulverized;

[0036] S5, add the deionized water that weight is 3% of solid particle weight to the solid particle obt...

Embodiment 3

[0038] A preparation method of inorganic modified starch fluid loss reducer for drilling fluid, the steps are as follows:

[0039] S1. Dispersing 100 parts by weight of cassava flour into 200 parts by weight of deionized water to obtain a starch suspension, adding sodium hydroxide to adjust the pH of the starch suspension to 7;

[0040] S2. Warm up the starch suspension to 40°C, add 1.8 parts by weight of sodium trimetaphosphate, and react at 40°C for 4 hours while stirring;

[0041] S3. Continue to add 4 parts by weight of acetic anhydride to the reaction solution obtained in step S2, and continue to react at 40° C. for 4 hours while stirring; and add sodium hydroxide after the reaction to adjust the pH of the reaction product to 7;

[0042] S4, rotary evaporation removes the solvent in the reaction product liquid, and the obtained solid product is dried and pulverized;

[0043] S5, add the deionized water that weight is 3% of solid particle weight to the solid particle obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com